PdNiW/C ternary alloy nano catalyst and preparation method thereof

A nano-catalyst, ternary alloy technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of limited research on direct ethanol fuel cells and no basic research. Problems such as invention reports, to avoid concentrated growth, avoid agglomeration, and have good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

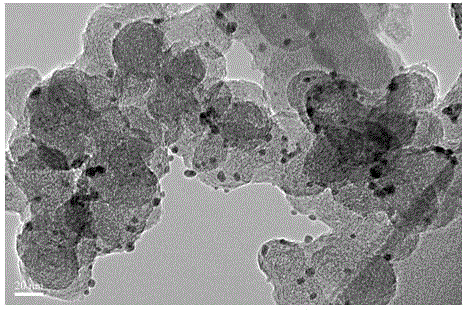

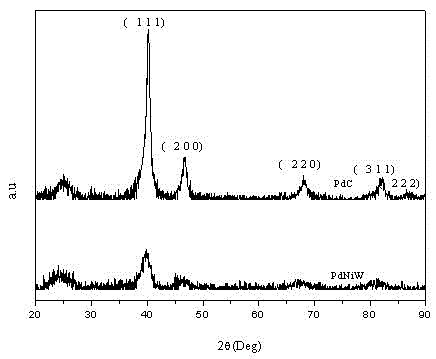

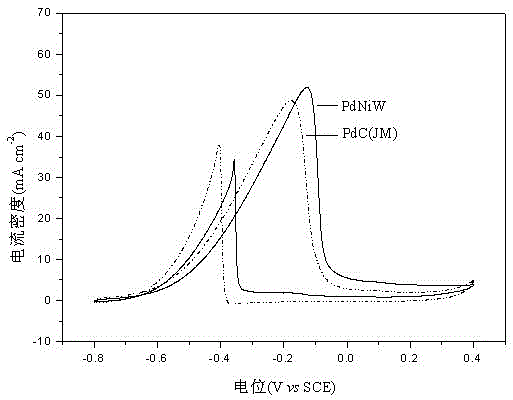

[0059] A PdNiW / C ternary alloy nano catalyst is a PdNiW / C ternary alloy nano catalyst formed with Pd, Ni and W as active centers and XC-72 activated carbon as a carrier;

[0060] The amount of the active center of the PdNiW / C ternary alloy nanocatalyst and the carrier XC-72 activated carbon is calculated according to the mass ratio, that is, the quality of the XC-72 activated carbon: the total mass of Pd, Ni and W is 4:1;

[0061] In the active center of the PdNiW / C ternary alloy nanocatalyst, calculated by molar ratio, Pd:Ni:W is 7:2:1.

[0062] The preparation method of above-mentioned a kind of PdNiW / C ternary alloy nano-catalyst, concrete steps are as follows:

[0063] (1), 11.86mgPdCl 2 Dissolve in 50ml ethylene glycol solution, ultrasonic for 1h to form solution 1;

[0064] (2), add 0.5g L successively to the solution 1 formed in step (1) -1 NiCl 2 ·6H 2 O in ethylene glycol solution 9.1ml, 1g L -1 Na 2 WO 4 2.8ml of ethylene glycol solution, adjust the pH value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com