Light-emitting diode (LED) array packaging light source module based on lead frame

A technology of LED array and lead frame, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of LED chip heat dissipation and mechanical protection, and achieve the effects of improving life, simplifying the manufacturing process, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

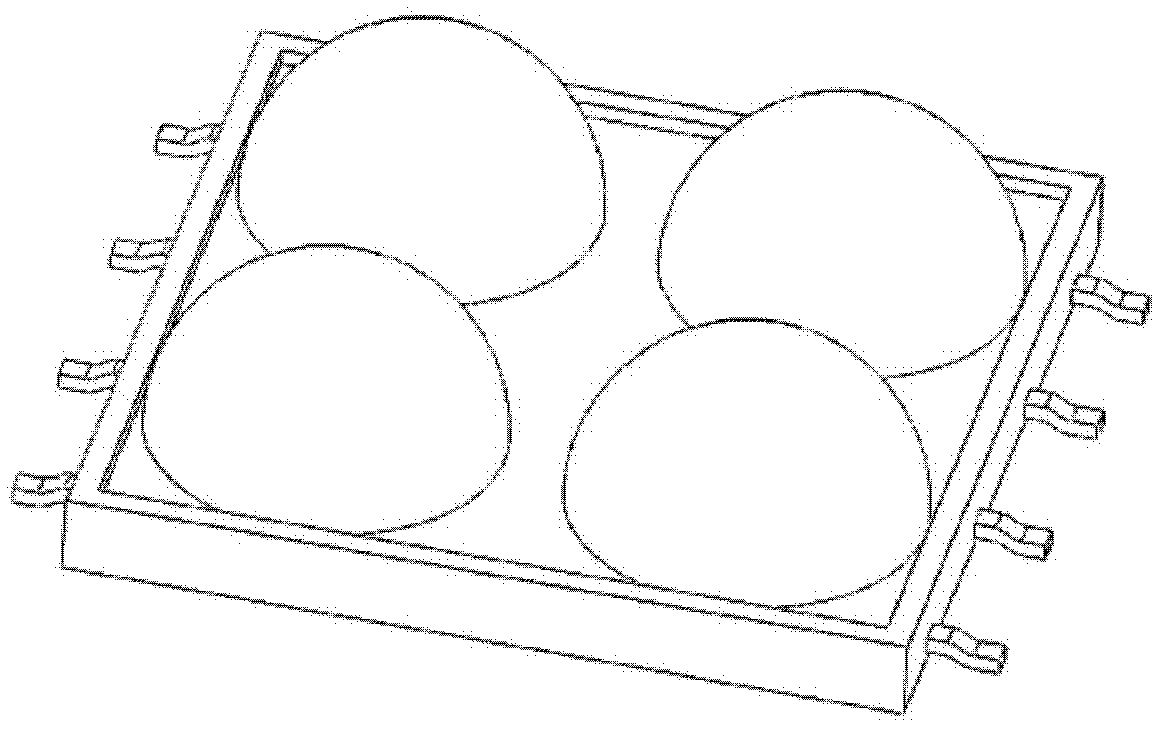

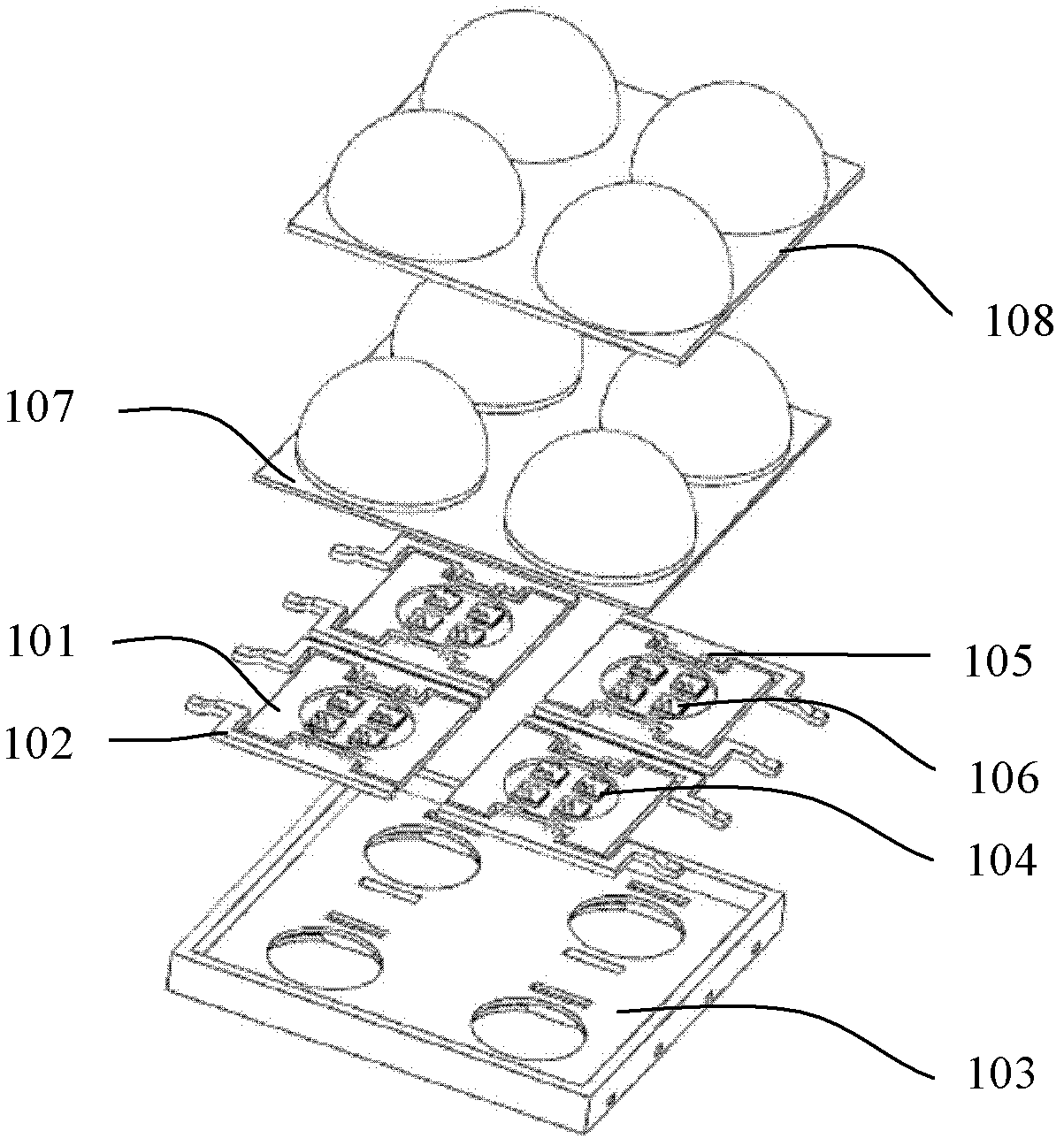

[0036] see Figure 1 to Figure 13 , this embodiment includes: a plate-shaped heat dissipation substrate 101, a lead frame 102, a molding compound 103 for insulating and providing structural support, an LED chip array 104, metal leads 105, a fluorescent powder silica gel mixture 106, silica gel 107, and an integral lens Array 108 .

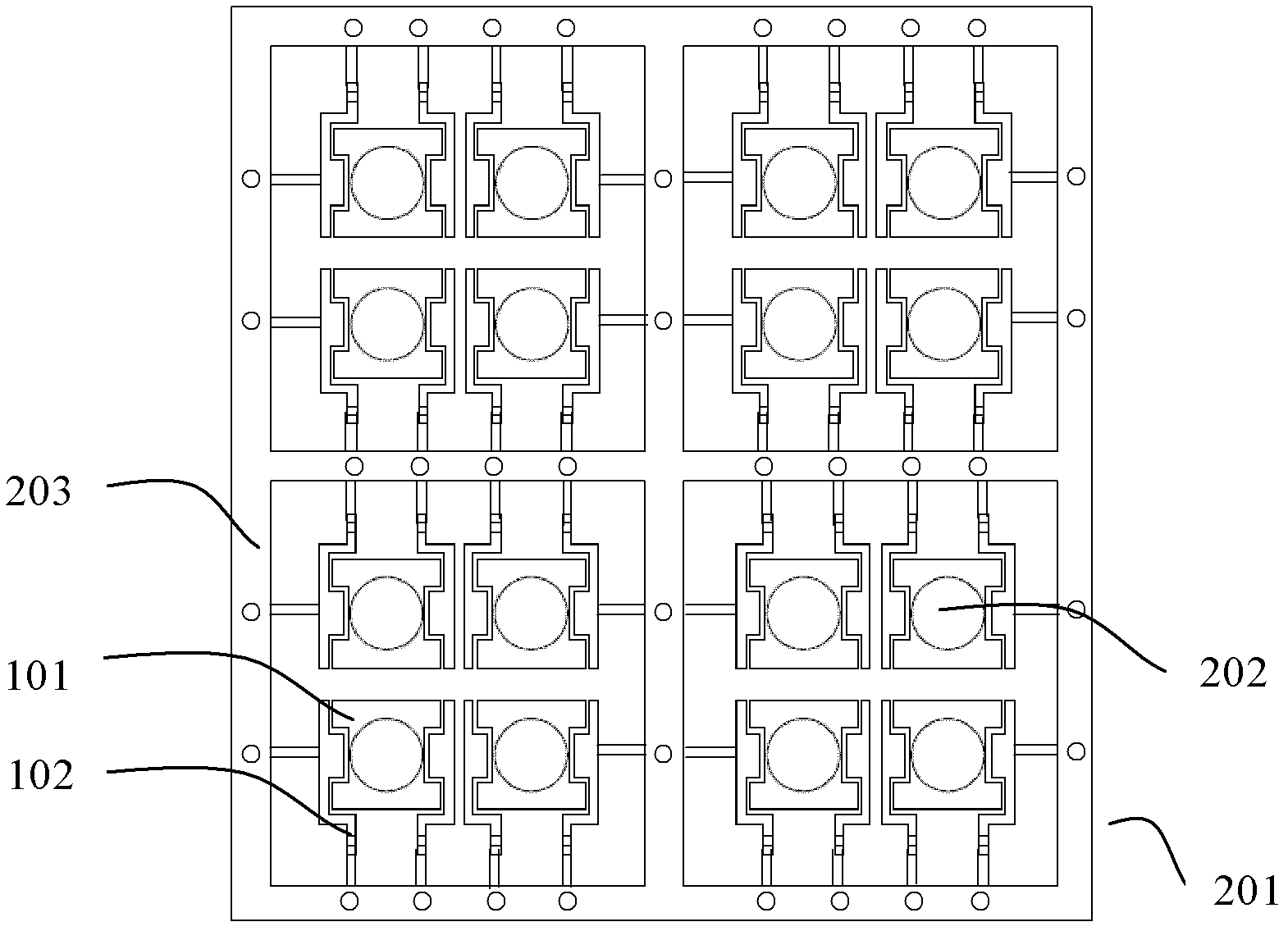

[0037] The plate-shaped heat dissipation substrate 101 and the lead frame 102 are made by stamping process. The process is as follows: take a thin metal plate with a thickness of 0.1-5 mm, and make a stamping die that meets the requirements. The stamping process is carried out in two steps. The first step is to punch out a circular groove 202, and the depth of the groove is 0 -0.3 mm, the second step is stamping to separate the heat dissipation substrate 101, the lead frame 102 and the support 203. After the stamping is complet...

Embodiment 2

[0043] Embodiment 2 is the same as Embodiment 1, except that the silica gel phosphor mixture is filled into the circular groove 202 for mounting the LED chip array 104. Since the depth of the circular groove 202 is between 0-0.3 mm During this time, a uniform phosphor layer 106 is coated on the surface of the LED chip by this simple dispensing method to convert the blue light emitted by the blue LED chip into white light. It is between 20 degrees and 90 degrees.

Embodiment 3

[0045] Embodiment 3 is the same as Embodiment 1, except that the shape of the lens fixing slot is an inverted trapezoid, and the edge of the lens array 108 is an inverted trapezoid matched with it, as Figure 14 shown. The fixing of the lens array 108 is ensured through the cooperation of the inverted trapezoidal fixing slot 303, and the reliability of the LED packaging module is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com