Method for trapping low molecular volatile substances in polypropylene

A technology of volatile substances and low molecular weight, which is applied in the field of analysis of volatile substances in solids. It can solve the problems of expensive headspace sampler, poor parallelism and representativeness, unstable analysis results, etc., and achieve simple and easy analysis steps. , a large sample size, and the effect of ensuring environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

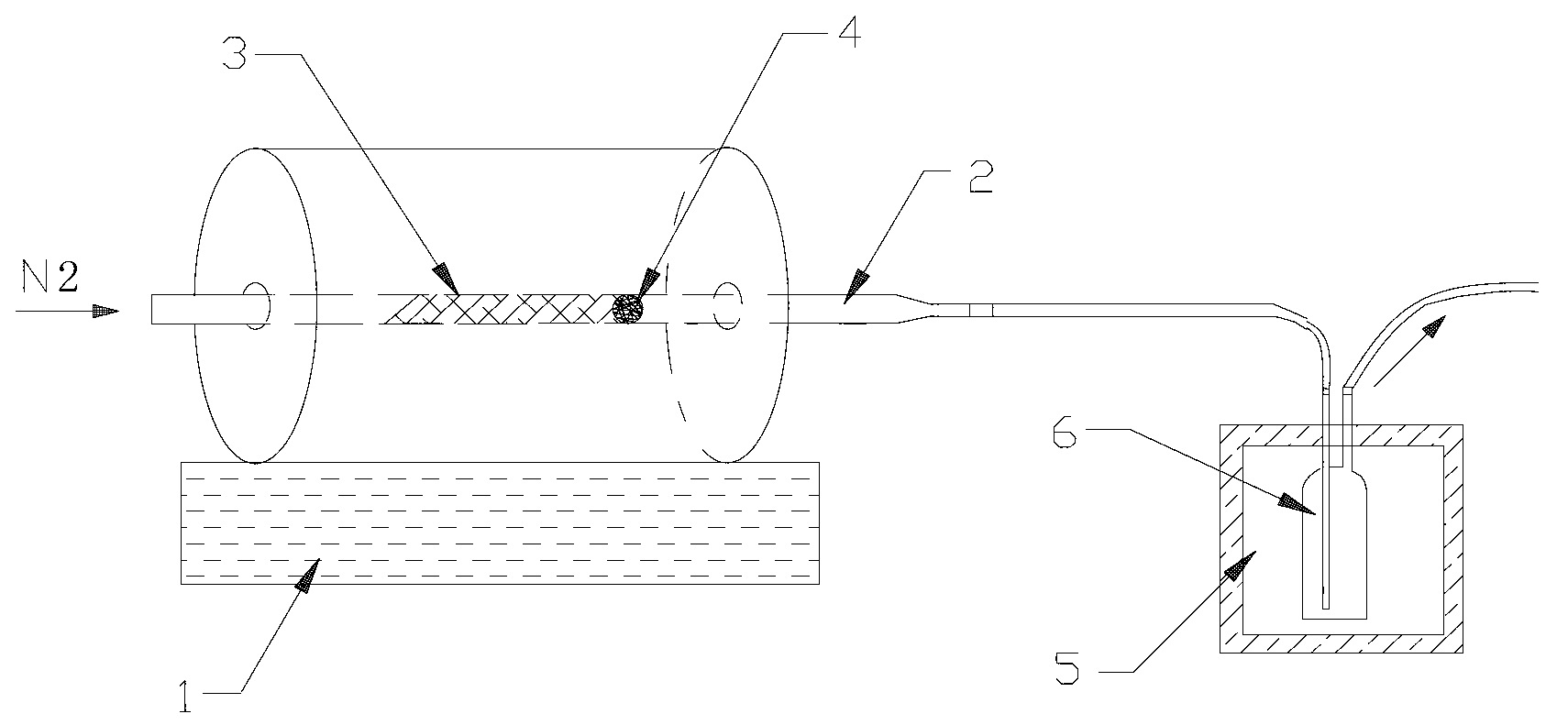

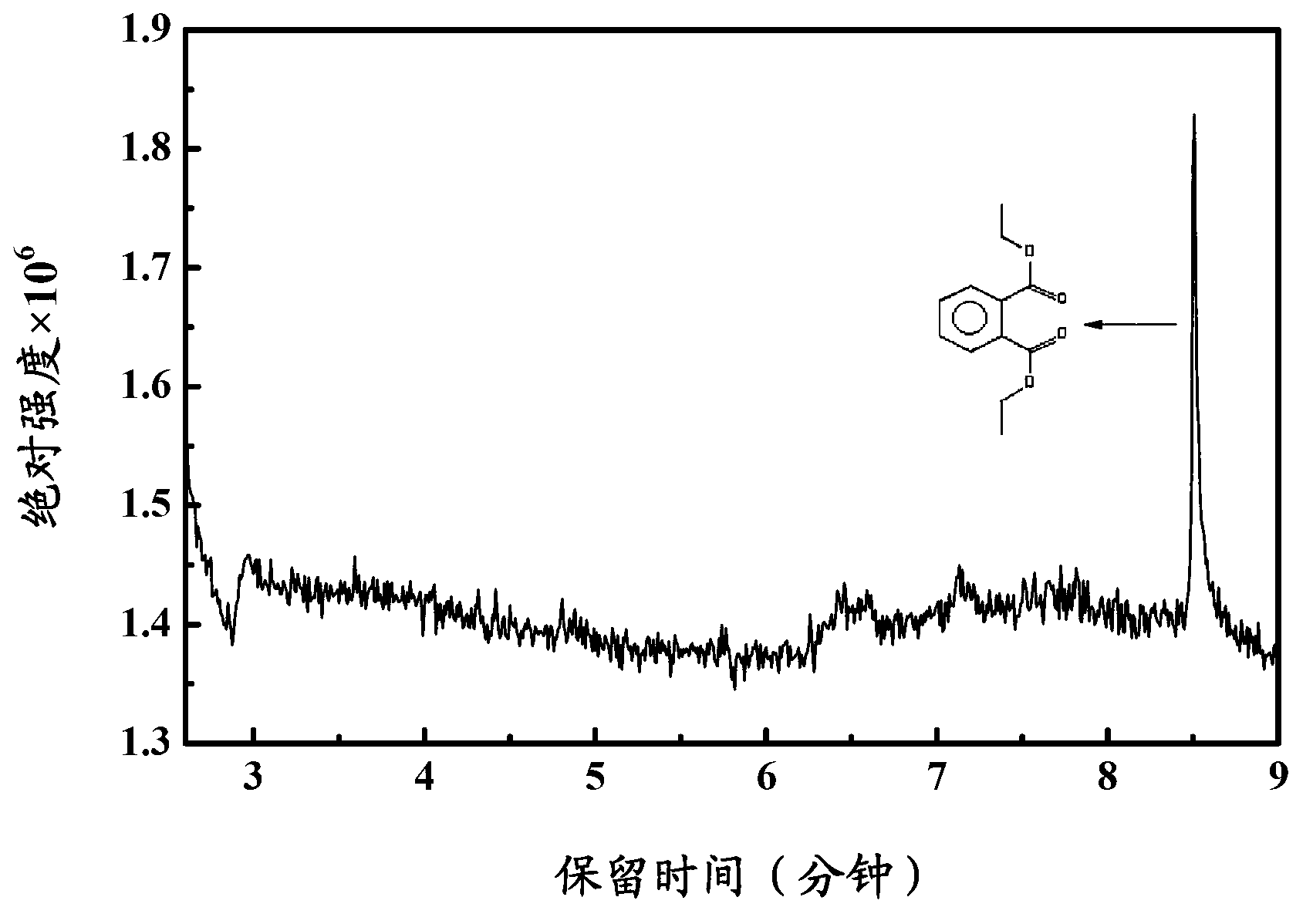

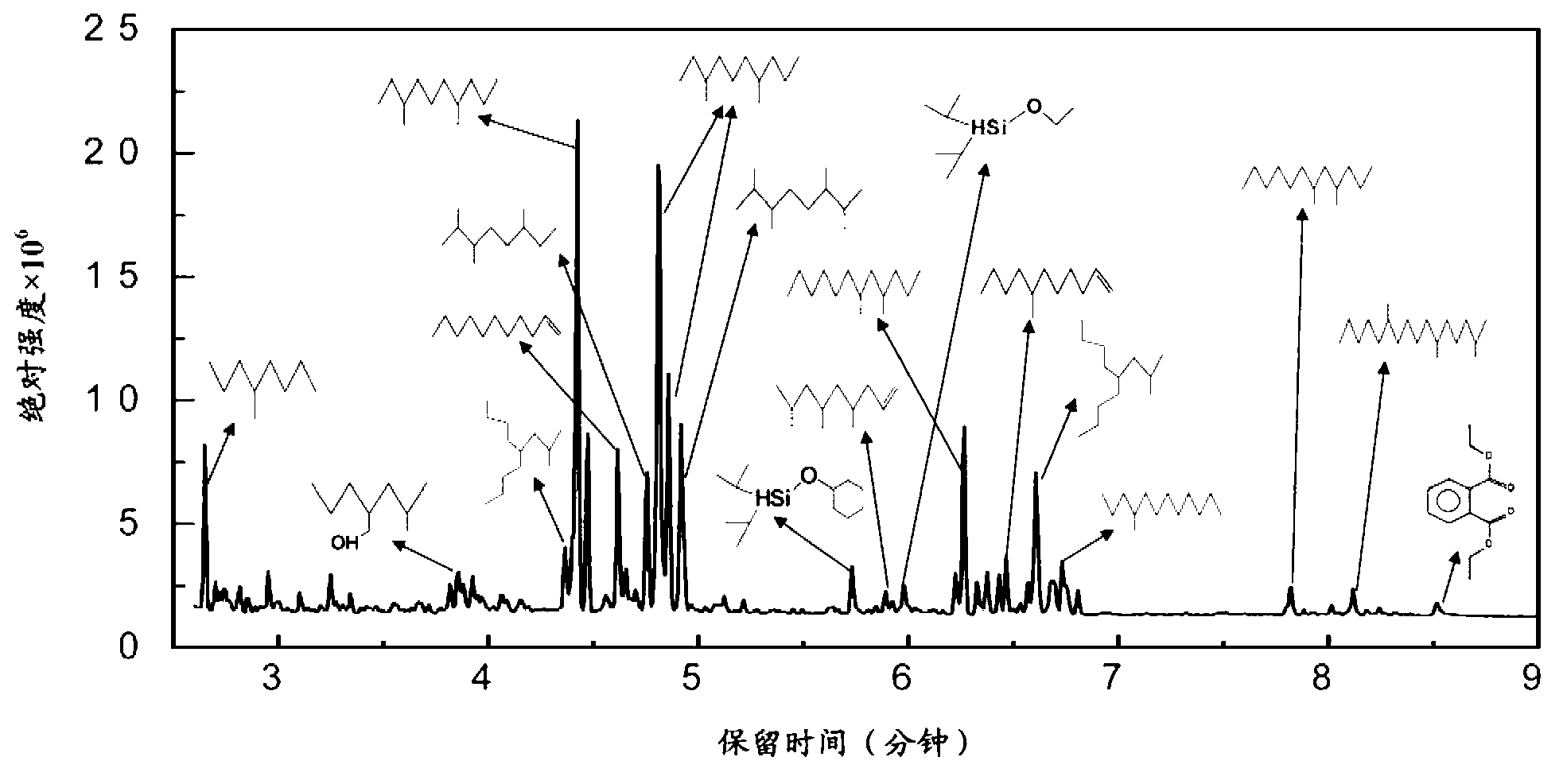

[0048] The quartz glass tube 2 is placed in the tubular heating furnace 1; Nitrogen gas is passed into the system until no air exists in the system, and then nitrogen gas is passed into one end of the quartz glass tube 2 at a constant speed of 20 mL / min, The other end of the quartz glass tube 2 is connected to the bubble counter 6 in the liquid nitrogen cold hydrazine 5; the quartz glass tube 2 is heated for 60 min under a nitrogen flow and a constant temperature of 140° C.; at the same time, the glass tube is 2. The end gas is passed into the bubble counter 6 in the liquid nitrogen cold hydrazine 5 for condensation and concentration. After the desorption-condensation and concentration is completed, the bubble counter 6 containing the concentrate is placed at room temperature. After the temperature was stabilized, the gas phase components and the residual liquid phase components were collected and analyzed respectively by gas chromatography-mass spectrometry. see results fig...

Embodiment 2

[0052] In addition to weighing 30g of polypropylene sample 1, the heating temperature of the tubular heating furnace 1 is 100°C, the thermal desorption time is 500min, the inner diameter of the quartz glass tube 2 is 15mm, and the flow rate of the carrier gas is 15mL / min , using the same steps as in Example 1 for processing. The qualitative results of GC-MS detection and analysis of gas phase components and residual liquid phase components are the same as those in Figure 3.

Embodiment 3

[0054] In addition to weighing 70g polypropylene sample 1, the heating temperature of the tubular heating furnace 1 is 150°C, the thermal desorption time is 200min, the inner diameter of the quartz glass tube 2 is 35mm, and the flow rate of the carrier gas is 25mL / min , using the same steps as in Example 1 for processing. The qualitative results of GC-MS detection and analysis of gas phase components and residual liquid phase components are the same as those in Figure 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com