Waterproof treatment method for magnesium refractory bricks

A processing method and technology for refractory bricks are applied in the waterproof field of magnesia refractory bricks, which can solve the problems of narrow application range and unsuitable refractory bricks, etc., and achieve the effects of improving service life, high hydration resistance and compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The waterproof treatment of magnesia-chrome bricks used in RH refining furnace, the dipping pipe of RH refining furnace widely adopts double-layer structure: the inner lining is built with magnesia-chrome bricks, and the outer layer is made of high-alumina castables. Due to the large amount of moisture carried by the latter, it will cause hydration damage to the magnesia-chrome bricks of the working layer under high temperature conditions. Therefore, it is necessary to waterproof the magnesia-chrome bricks used in the RH refining furnace:

[0021] The chemical indicators of magnesia-chrome bricks are shown in Table 1.

[0022] Table 1

[0023] Element

burn reduction

SiO 2

Al 2 o 3

Fe 2 o 3

CaO

MgO

Cr 2 o 3

Percentage (%)

0.16

1.59

4.54

5.34

1.21

75.64

11.52

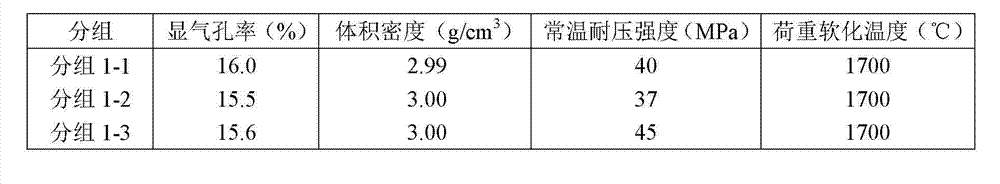

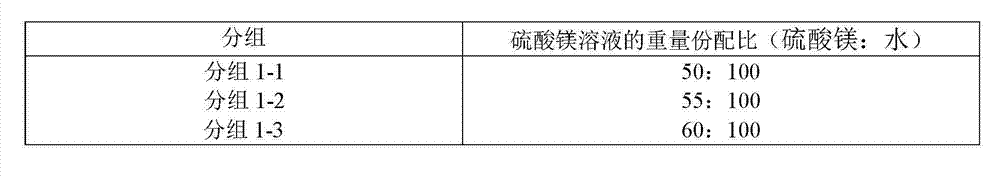

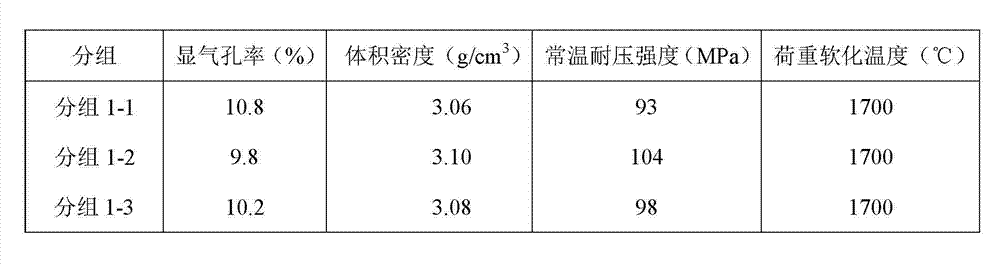

[0024] The physical indicators of magnesia-chrome bricks before impregnation are shown in Table 2.

[0025] Table 2 ...

Embodiment 2

[0040] Waterproof treatment of burnt magnesia bricks for metallurgical converters. Most metallurgical converters use double-layer masonry structures. The working layer uses magnesia-carbon bricks. Water enters the interior of the permanent layer from the furnace mouth along the furnace shell, and the formation of water vapor at high temperature will cause hydration of the permanent layer magnesia bricks, resulting in pulverization and damage of the magnesia bricks.

[0041] The chemical indicators of burnt magnesia bricks are shown in Table 5.

[0042] table 5

[0043] Burnt magnesia brick

burn reduction

SiO 2

Al 2 o 3

Fe 2 o 3

CaO

MgO

Chemical indicators

0.2

3.77

0.66

0.88

1.75

92.74

[0044] The physical indicators of the burnt magnesia bricks before impregnation are shown in Table 6.

[0045] Table 6

[0046]

[0047] Table 7

[0048]

[0049] The specific operation steps of embodimen...

Embodiment 3

[0059] Waterproof treatment of magnesia-alumina spinel bricks for parallel flow regenerative Maerz active lime kiln, most of the refractory bricks for the working layer of parallel flow regenerative Maerz active lime kiln are magnesia-alumina spinel bricks, and more fuel is used Water gas and natural gas, etc., a large amount of water brought in during combustion will condense on the upper wall of the shaft kiln and flow downward, causing hydration of the magnesia refractory bricks in the working layer; when limestone raw materials stored in the open air enter the kiln, rainwater and Ice and snow, fire clay, castables and concrete used in the masonry process will also bring additional moisture to the kiln, which will cause hydration of the magnesia-aluminum spinel bricks in the working layer during use. Therefore, the magnesia-aluminum spinel bricks used in the parallel flow regenerative Maerz active lime kiln need to be soaked in salt and waterproofed:

[0060] The chemical i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com