Computer numerically controlled (CNC) camshaft grinding machine

A technology for camshafts and grinding machines, which is applied to abrasive belt grinders, grinding machine parts, grinding/polishing equipment, etc. It can solve the problems of low grinding efficiency of grinding machines, reduce tool clearance, improve rough grinding efficiency, The effect of strengthening machine tool strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

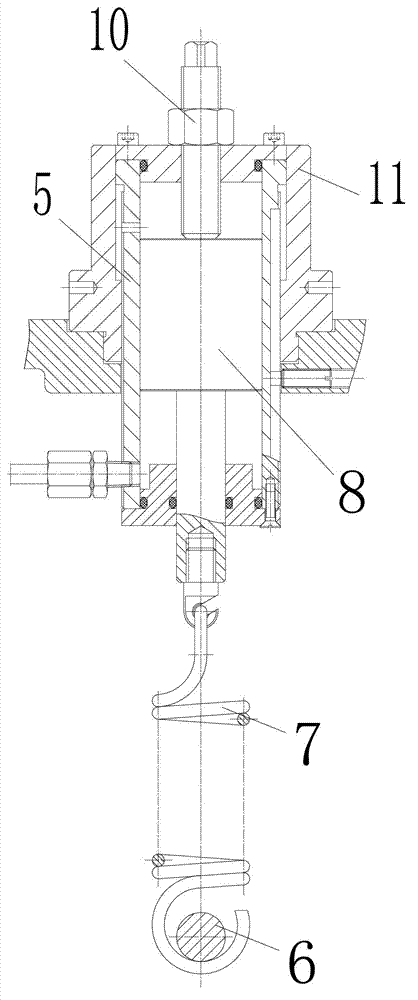

[0031] see Figure 1 to Figure 5 , CNC camshaft grinding machine, including machine tool 1 and electric spindle 2, the electric spindle is an electric spindle with an external planar joint hydrostatic bearing, and its outer box body adopts a closed cavity structure without leaving a window for oil pipe installation to enhance its integrity .

[0032] When using a high-speed CBN grinding wheel, the grinding wheel spindle can use a φ100mm high-rigidity, high-strength nitride steel spindle, and the bearing adopts an external plane gap throttling. The dynamic and static pressure oil chamber structure makes the grinding wheel spindle bearing stiffness up to 150 kg / micron.

[0033] The main shaft bearings include the main shaft front bearing 3 and the main shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com