Preparation method of heating type thermocouple liquid level measurement sensor

A technology of liquid level measurement and thermocouple, applied in liquid level indicators for physical variable measurement, etc., can solve the problem that armored cables cannot distinguish the gas-liquid interface, and armored cables cannot distinguish the gas-liquid interface, which restricts the development of liquid level measurement technology and other issues to achieve the effect of ensuring sensitivity and accuracy, high resolution, good accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the heating type thermocouple liquid level measuring sensor is characterized in that it has the following steps, see figure 1 :

[0031] Production of heating elements:

[0032] 1) Take heating wire 7, straighten and wipe clean. Fold the heating wire in half and fix one end of the folded half on the ceramic tube 8, and clamp the other end on the bobbin, wind the heating wire on the ceramic tube at equal distances in a clockwise direction, and then merge the two ends of the heating wire on the ceramic tube. Fix one end of the tube. The heating wire is made of Cr20Ni80 material with melting point of 1400℃, density of 8.4g / mm3, elongation ≥20, resistivity of 1.09±0.05μΩ.m, thermal conductivity of 60.3 kj / mh℃ and linear expansion coefficient of 18, heating The diameter of the wire is 0.18~0.22mm; the diameter of the ceramic tube is 1.8~2.2mm, and the thickness is 0.2~0.3mm.

[0033] 2) Apply a layer of glaze powder on the outer surface of the ceramic t...

Embodiment 1

[0048] The heating type thermocouple liquid level measuring sensor is prepared by adopting the above preparation method. In order to further verify the reproducibility of the sensor, in this embodiment, a nickel lead with a low resistivity is selected as the lead wire of the heating element, and for reliable and stable resistance, Ni20Cr80 is selected as the heating wire. For accurate and reliable measurement, choose Alumel as the negative thermocouple wire, Chromel as the positive thermocouple wire, and select N7 for the nickel lead.

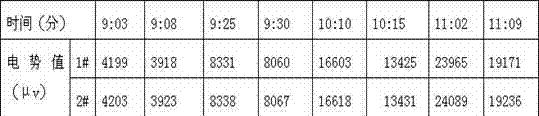

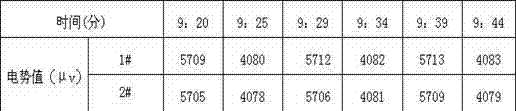

[0049] When working, the heating element is supplied with a DC constant current or constant voltage power supply. After its working voltage or current is stable, its potential value is measured and converted into the corresponding temperature value; then the sensor that is still heating and in a stable state Immerse into a liquid with higher thermal conductivity, observe the change of its potential value, and convert it to the corresponding temper...

Embodiment 2

[0062] The specific steps for manufacturing a heated thermocouple level measurement sensor are as follows:

[0063] Prepare the heating element:

[0064] 1) Fold the heating wire in half, and fix one end of the folded end on the ceramic tube, and double-wind the other end on the ceramic tube at an equal distance, and then gather the two ends of the heating wire on one end of the ceramic tube and fix it. The heating wire is made of Cr20Ni80 material with melting point of 1400℃, density of 8.4g / mm3, elongation ≥20, resistivity of 1.09±0.05μΩ.m, thermal conductivity of 60.3 kj / mh℃ and linear expansion coefficient of 18, heating The diameter of the wire is 0.18~0.22mm; the diameter of the ceramic tube is 1.8~2.2mm, and the thickness is 0.2~0.3mm.

[0065] 2) Coating a layer of glaze powder on the outer surface of the ceramic tube wrapped with heating wire described in step 1), sintering at a high temperature of 800°C for 10 minutes, and cooling to room temperature to obtain a heating el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com