Method for preparing 2-amino-4, 6-dimethoxypyrimidine

A technology of dimethoxypyrimidine and dimethyl cyanomalonimide, which is applied in organic chemistry and other fields, can solve problems such as high cost of malononitrile, easy decomposition and polymerization, and unstable temperature, and achieve less waste , simple operation, easy solvent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

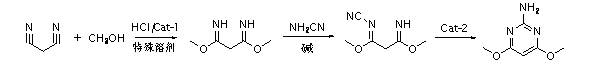

[0038] (1) Synthesis of Dimethoxypropanediamidine (ADMP01)

[0039]At room temperature, add malononitrile (132.0g / 2.0mol) methanol solution (1000ml) and solid titanium tetrachloride (2.6g) into a 2L four-neck flask, stir and mix well, pass dry hydrogen chloride into the system Gas, keep the pressure of 0.1 ~ 0.5MPa, heat the reaction at 25 ~ 35 ℃ and stir for 4 hours, stop the reaction, degas, filter, and obtain the solution of dimethoxypropanediamidine, which can be directly used in the next reaction.

[0040] (2) Synthesis of Dimethyl Cyanomalonimide (ADMP02)

[0041] Add 600ml of buffer solution prepared by mixing disodium hydrogen phosphate (71.0g / 0.5mol) and sodium bicarbonate (25.2g / 0.3mol) into a 2L four-neck flask, stir, cool down to below 0°C in an ice-salt bath, add 50 % NH 2 CN aqueous solution (214.2g / 2.55mol), add the solution of dimethoxypropanediamidine (ADMP01), the pH value of the reaction solution is maintained at 8~9 during the dropwise addition, after the...

Embodiment 2

[0046] (1) Synthesis of Dimethoxypropanediamidine (ADMP01)

[0047] Add malononitrile (132.0g / 2.0mol) and methyl acetate solution (1000ml) of methanol (320.0g / 10.0mol) and zirconia (3.0g) into a 2L four-necked flask, cool to 0~ Stir and mix well at 10°C, pass dry hydrogen chloride gas into the system, keep the pressure of 0.1~0.5MPa, stir for 7 hours, stop the reaction, degas, filter, and obtain the solution of dimethoxypropanediamidine, which can be used directly react in the next step.

[0048] (2) Synthesis of Dimethyl Cyanomalonimide (ADMP02)

[0049] Add 600ml of buffer solution prepared by disodium hydrogen phosphate (28.4g / 0.2mol) and ammonium bicarbonate (39.5g / 0.5mol) into a 2L four-neck flask, stir, cool down in an ice-salt bath to below 0°C, add 50% NH 2 CN aqueous solution (214.2g / 2.55mol), add the solution of dimethoxypropanediamidine (ADMP01), the pH value of the reaction solution is maintained at 8~9 during the dropwise addition process, after the addition is...

Embodiment 3

[0054] (1) Synthesis of Dimethoxypropanediamidine (ADMP01)

[0055] At room temperature, add malononitrile (132.0g / 2.0mol) and methyl tert-butyl ether solution (1000ml) and cobalt chloride (1.5g) of methanol (320.0g / 10.0mol) in a 2L four-necked flask, Stir and mix well, pass dry hydrogen chloride gas into the system, keep the pressure of 0.1-0.5MPa, keep warm at 25-35°C and stir for 4 hours, stop the reaction, degas, filter, and obtain the solution of dimethoxypropanediamidine , which can be directly used in the next reaction.

[0056] (2) Synthesis of Dimethyl Cyanomalonimide (ADMP02)

[0057] Add 3% ammonia water (566.7g / 1.0mol) into a 2L four-neck flask, cool down in an ice-salt bath to below 0°C, add 50% NH 2 CN aqueous solution (214.2g / 2.55mol), add the solution of dimethoxypropanediamidine (ADMP01), and control the feeding speed by detecting the pH value of the system. During the dropping process, the pH value of the reaction solution is maintained at 8-9. After the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com