Method and device for increasing concentration of iron ions in artificial rutile mother solution

A technology of artificial rutile and mother liquor, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Due to the complex process flow and other problems, the effect of reducing the heating and concentration time, completing the reaction and improving the heat transfer can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

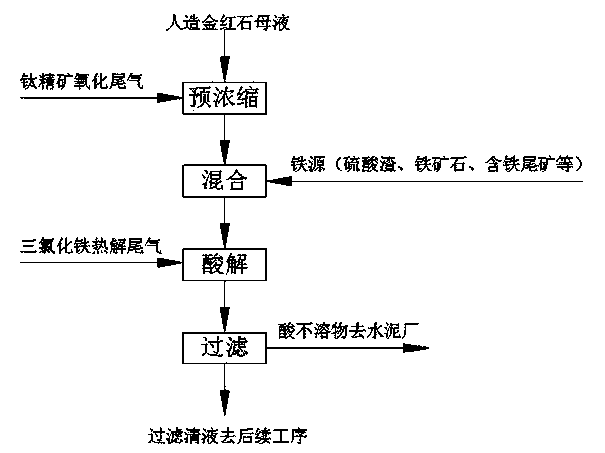

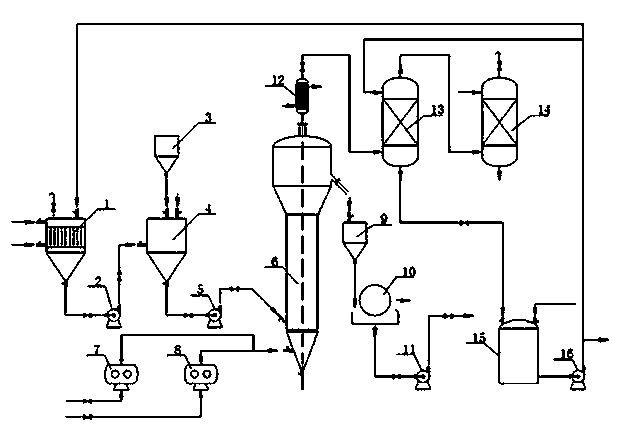

[0055] (1) Pass the tail gas from the titanium concentrate oxidation tower into the pre-evaporator 1 to heat and pre-concentrate the artificial rutile mother liquor, and the Fe in the mother liquor 3+ The concentration is increased to above 150g / L, and at the same time, the temperature of the mother liquor is raised to 85-110°C.

[0056] (2) The pre-concentrated mother liquor enters the premixing tank 4 through the hydrochloric acid pump 2, and is mixed with the sulfuric acid slag provided by the iron source silo 3 in the premixing tank 4 to form a solid-liquid mixed slurry;

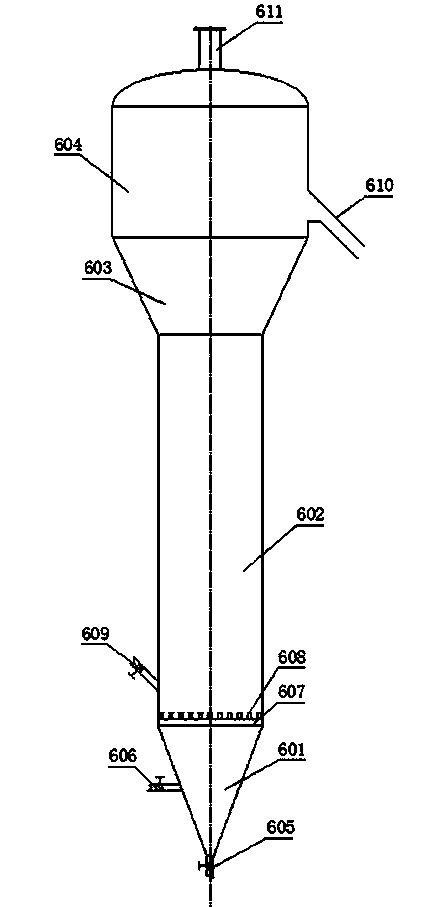

[0057] (3) Add the solid-liquid mixed slurry into the fluidized bed reactor 6 through the anticorrosion slurry pump 5, and the gas feed port 606 of the fluidized bed reactor is fed with the mixed gas of hydrogen chloride gas and compressed air, wherein the hydrogen chloride gas is The hydrogen chloride tail gas produced by the pyrolysis of ferric chloride keeps the acid concentration in the slurry consta...

Embodiment 2

[0061] The same operation as in Example 1, the difference is that the hydrogen chloride gas fed into the gas feed port 606 is other by-product hydrogen chloride or hydrogen chloride generated by the combustion of hydrogen chloride, rather than the hydrogen chloride tail gas generated by the pyrolysis of ferric chloride.

[0062] The above steps process 1 m 3 The mother liquor consumes a total of 400,000 kcal of heat energy, which is provided by the waste heat of the titanium concentrate oxidation tail gas and external heat.

Embodiment 3

[0064] The same operation as in Example 1, the difference is that the iron source provided by the iron source silo 3 is iron-containing tailings or iron concentrate, not sulfuric acid slag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com