Polyvinylidene-fluoride-based composite fibrous membrane, preparation method and application thereof

A technology of polyvinylidene fluoride and composite fiber membrane, which is applied in the direction of textiles and papermaking, structural parts, electrical components, etc. It can solve the problems of difficult control of diaphragm pore size and porosity, elongation rate should not be too high, diaphragm perforation, etc., to achieve Improve high current charge and discharge performance, cheap raw materials and equipment, good lyophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

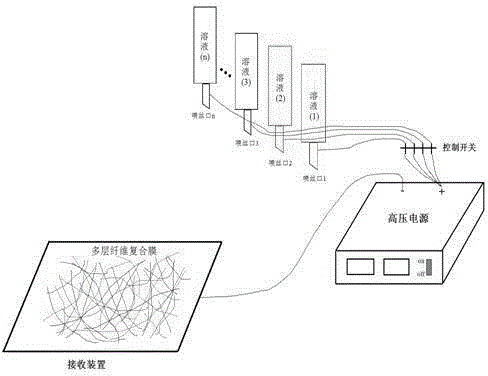

Method used

Image

Examples

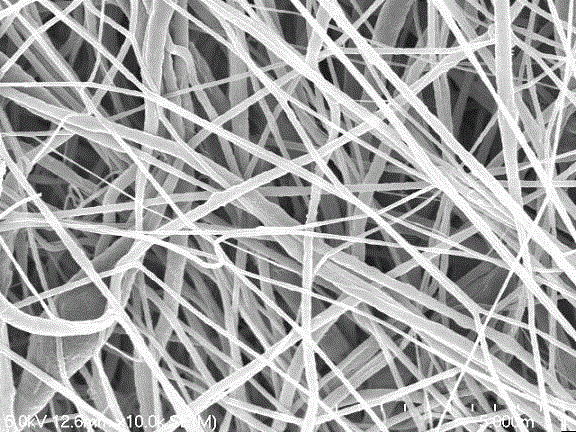

Embodiment 1

[0040] 1.5g PVDF was dissolved in a mixed solvent of 8mL DMF and 2mL acetone, and stirred for 20 hours under 60°C water bath conditions to obtain a 15% PVDF spinning solution. The spinning solution was poured into a container connected to the spinneret for electrospinning. The spinning conditions were as follows: the spinning voltage was 20kV, the inner diameter of the spinneret needle was 0.45mm, the distance between the needle and the collecting device was 15cm, an aluminum plate was used to collect the fibers, and the spinning process was carried out for 1 h to obtain a PVDF fiber membrane. SEM photos such as figure 2 As shown, the product has a fiber morphology with nodes on the fibers, and the fiber diameter is uneven, with an average diameter of 195 nm. The mean diameter in the context of the present invention refers to the overall average of the diameters of the fibers, which are measured at the locations of non-protrusions in the fibers.

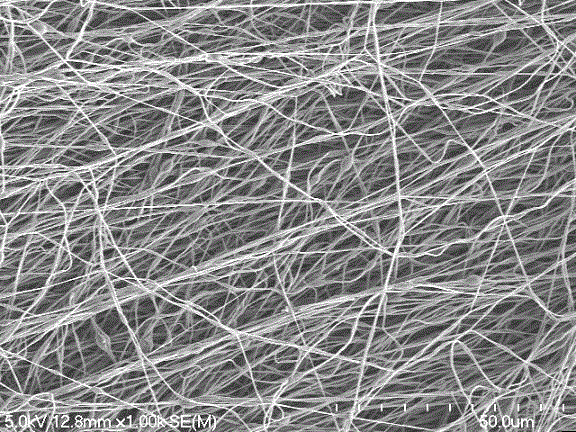

Embodiment 2

[0042] Dissolve 0.8 g PVDF and 0.4 g PAN in 10 mL of DMF solvent, and stir in a water bath at 60° C. for 20 hours to obtain a mixed solution of 8% PVDF-4% PAN. The mixed solution was poured into a container connected to the spinneret for electrospinning. The spinning conditions are: the spinning voltage is 20kV, the inner diameter of the spinneret needle is 0.45mm, the distance between the needle and the collecting device is 15cm, an aluminum plate is used to collect the fibers, and the spinning process is carried out for 1h to obtain a PVDF-PAN composite fiber membrane . SEM photos such as image 3 As shown, the product has a fibrous morphology with nodes on the fibers and an average fiber diameter of 452 nm.

Embodiment 3

[0044] 1.6g PVDF and 0.4gPMMA were dissolved in 7.5mL DMF and 2.5mL acetone solvent, and stirred for 20 hours under 60°C water bath condition to obtain a 16%PVDF-4%PMMA mixed solution. The mixed solution was poured into a container connected to the spinneret for electrospinning. The spinning conditions are: the spinning voltage is 15kV, the inner diameter of the spinneret needle is 0.45mm, the distance between the needle and the collecting device is 15cm, an aluminum plate is used to collect the fibers, and the spinning process is carried out for 1h to obtain a PVDF-PMMA composite fiber membrane . SEM photos such as Figure 4 As shown, the product has a fibrous morphology with an average fiber diameter of 728 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com