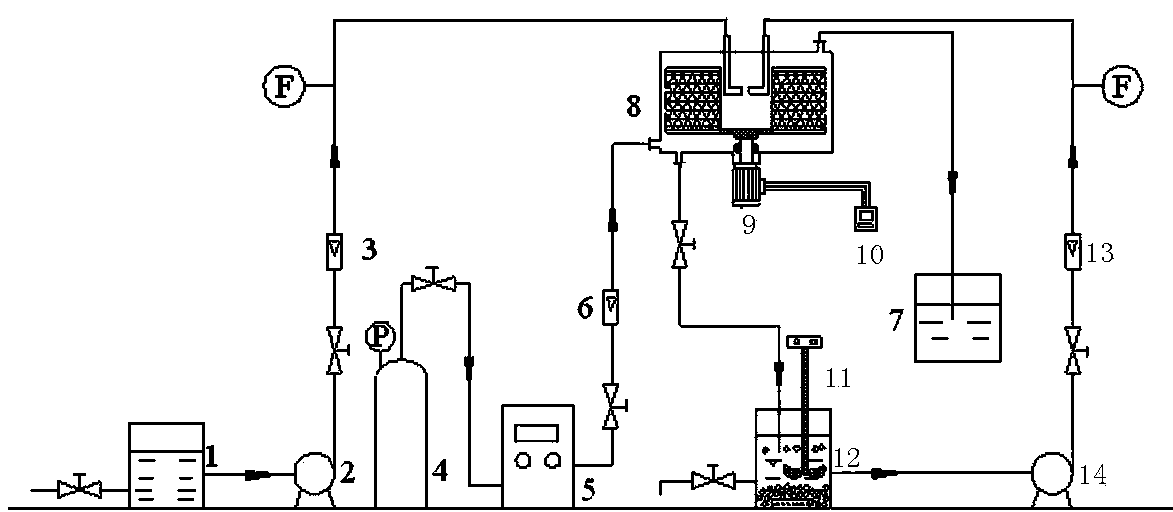

Method and device for treating wastewater by advanced oxidation process

A technology for wastewater treatment and advanced oxidation, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. It can solve the problems of low utilization rate, large power consumption, and high treatment cost, and achieve The effects of improved ozone utilization rate, improved treatment efficiency, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

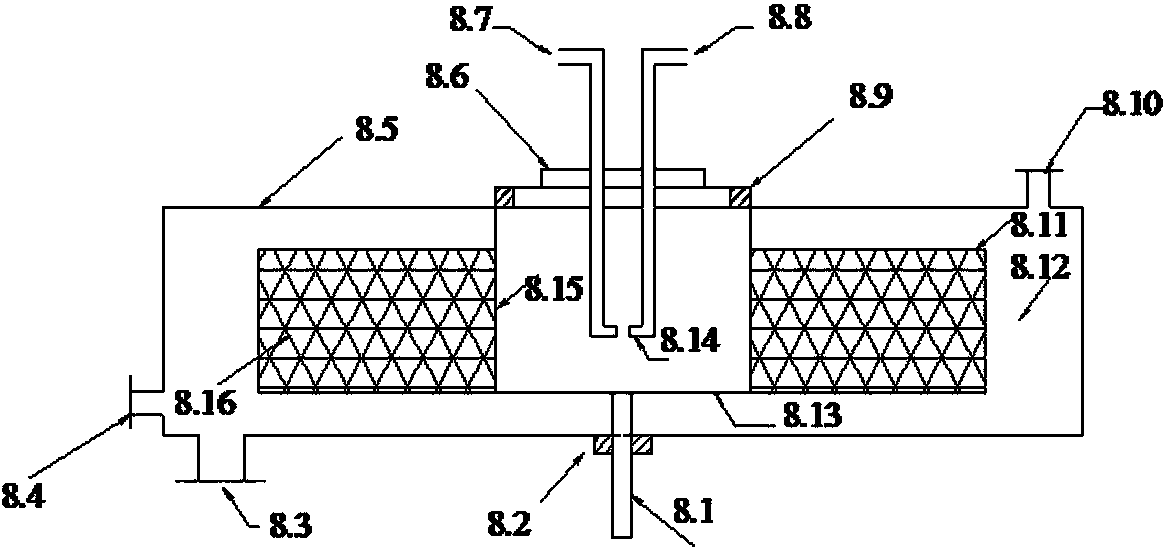

[0050] Example 1: Treatment of high-concentration printing and dyeing wastewater in a printing and dyeing factory. Wastewater is dark brown, chromaticity 1200~1500 times, COD Cr 15000~32000mg / L. Adjust the pH of the wastewater to 2. Micro-electrolysis was used to pretreat 15L of wastewater, the amount of iron powder added was 30g / L, the mass ratio of iron to carbon was Fe:C=1:1, the reaction time was 1.5h, and the stirring speed of the agitator was 800r / min. COD Cr Reduced by 30~50%, chromaticity decreased by about 20%; adjust the volume flow rate of micro-electrolyzed water and hydrogen peroxide to 5:1, the added H 2 o 2 The amount is about 0.05mol / L, and the liquid-gas ratio of micro-electrolysis water and ozone is adjusted to 50L / m 3 , the ozone concentration is 10mg / L, COD after 2 hours of reaction Cr The removal rate reaches 60%, and the chroma removal rate reaches more than 95%. While using IS-RPB as a wastewater treatment device, the IS-RPB device has an inner di...

Embodiment 2

[0051] Embodiment 2: Treatment of nitrobenzene wastewater. The concentration of nitrobenzene in the wastewater is 300mg / L, and the pH value is adjusted to 2.5. Take 25L of water samples, and use micro-electrolysis p-nitrobenzene wastewater to pretreat, the reaction time is 1h, the stirring speed is 200r / min, the iron powder addition is 20g / L, and the iron-carbon mass ratio is 3:1. Its reduction rate is over 90%, and the liquid-gas ratio of micro-electrolysis water and ozone is 200L / m 3 , the ozone concentration is 30mg / L, adjust the flowmeter so that the volume flow ratio of the micro-electrolyzed water and hydrogen peroxide is 8:1, H 2 o 2 The concentration is 0.03mol / L, the rotating speed of the impinging flow rotating packed bed is 1500rpm, the inner diameter of the IS-RPB device is 8cm, the initial impact velocity is 4m / s, and the distance between the outlets of the two inlet pipes is 5 / 12 of the inner diameter of the rotating packed bed, made of stainless steel Porous ...

Embodiment 3

[0052] Example 3: Treatment of nitrotoluene waste water from a propellant and explosive factory. Wherein the concentration of trinitrotoluene in the wastewater is 20mg / L, the concentration of dinitrotoluene is about 100mg / L, and the biochemical coefficient is only 0.1. Adjust the pH to 3.0 with dilute sulfuric acid. Take 200L of water samples, and use micro-electrolysis to pretreat the wastewater. The amount of iron powder added is 10g / L, the mass ratio of iron to carbon is 0.5:1, the stirring speed is 500r / min, and the reaction time is 1.5h. More than % of nitro compounds are converted into aniline substances, adjust the volume flow ratio of micro-electrolysis effluent to hydrogen peroxide to 10:1, the concentration of hydrogen peroxide is 0.01mol / L, and the liquid-gas volume ratio of micro-electrolysis effluent to ozone is 400L / m 3 , the ozone concentration is 50mg / L, the impingement flow-rotating packed bed speed is 300rpm, the inner diameter of the IS-RPB device is 10cm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com