Method and device for treating wastewater by intensified micro-electrolysis-Fenton oxidation method

A technology for wastewater treatment and micro-electrolysis, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of toxic intermediate products, high treatment costs, secondary pollution, etc. Reach the effect of shortening the reaction time, simplifying the technological process and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

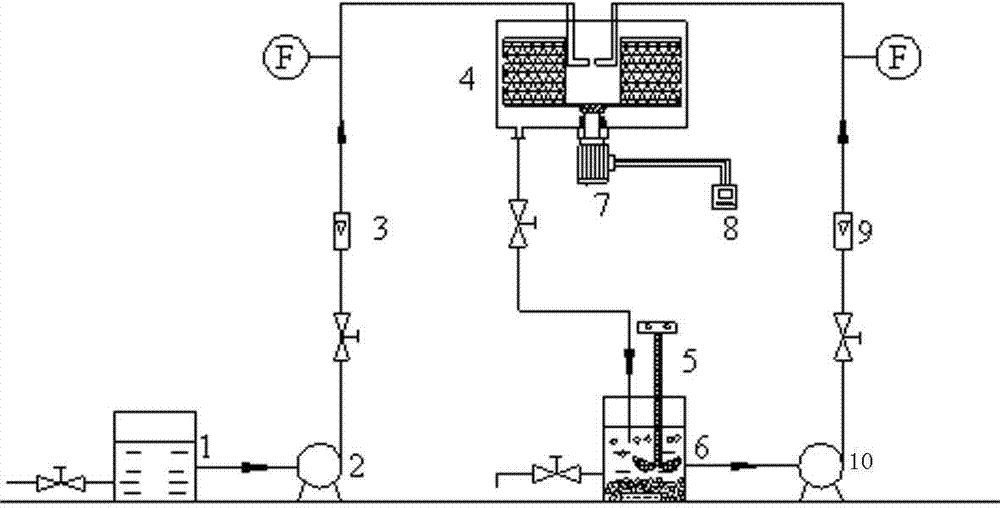

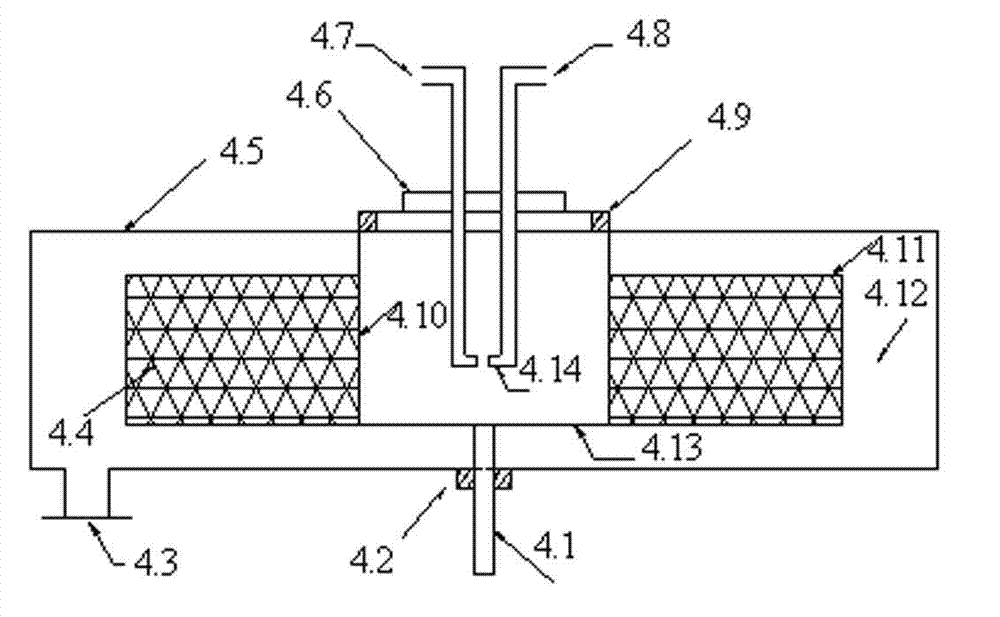

Method used

Image

Examples

Embodiment 1

[0052] Example 1: Treatment of high-concentration printing and dyeing wastewater in a printing and dyeing factory. Wastewater is dark brown, pH is 2.5, color is 1200~1500 times, COD Cr 15000~32000mg / L. Micro-electrolysis was used to pretreat 1.5L of wastewater, the amount of iron powder added was 10g / L, the mass ratio of iron to carbon was Fe:C=0.5:1, the reaction time was 1.5h, and the stirring speed of the stirrer was 400r / min. , COD Cr Reduced by 30~50%, chromaticity decreased by about 20%; adjust the volume flow rate of micro-electrolyzed water and hydrogen peroxide to 5:1, the added H 2 o 2 The amount is about 0.05mol / L, COD after 2 hours of reaction Cr The removal rate reaches 60~70%, and the chroma removal rate reaches more than 95%. However, using the impingement flow-rotating packed bed (IS-RPB) as the liquid-liquid contact and reaction device, the two fluids of hydrogen peroxide and waste water collide with each other at an initial velocity of 0.5m / s, using corr...

Embodiment 2

[0053] Example 2: Treatment of dinitrotoluene (DNT) in waste water from a propellant and explosive factory. The initial concentration of dinitrotoluene in wastewater is 400mg / L, and the biochemical coefficient is only 0.1. Micro-electrolysis is used to treat 2.0L of wastewater. At pH=3, the amount of iron powder added is 20g / L, and the mass ratio of iron to carbon Fe: C=1.5:1, the reaction time is 2h, and the stirring speed of the stirrer is 200r / min, more than 80% of the nitro compounds are converted into aniline substances, and the flow meter is adjusted so that the volume flow ratio of the micro-electrolyzed water and hydrogen peroxide is 8 :1,H 2 o 2 The concentration is 0.03mol / L, the speed of impinging flow-rotating packed bed (IS-RPB) is 1500rpm, and the initial velocity of the two fluids of hydrogen peroxide and wastewater colliding is 3m / s. After 40min of degradation, the pollutant removal rate reaches 95% % or more; while the waste water that has not been pretreate...

Embodiment 3

[0054] Embodiment 3: Treatment of TNT wastewater. The concentration of trinitrotoluene in the wastewater is 100 mg / L, and the pH value is adjusted to 2.0 with dilute sulfuric acid. Take 2L of water sample, and use micro-electrolysis to pretreat the wastewater. The amount of iron powder added is 30g / L, the mass ratio of iron to carbon is 3:1, the stirring speed is 800r / min, and the reaction time is 1.5h. More than % of nitro compounds are converted into aniline substances, adjust the volume flow ratio of micro-electrolysis water and hydrogen peroxide to 10:1, the concentration of hydrogen peroxide is 0.01mol / L, and the speed of impinging flow-rotating packed bed device (IS-RPB) is 300rpm , Hydrogen peroxide and waste water collide with each other at an initial velocity of 10m / s. Stainless steel porous corrugated plate is used as filler. After 50 minutes of reaction, the removal rate of organic pollutants in waste water reaches 97%. The biochemical coefficient is above 0.5; whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com