Oxidation-reduction resin film oxygen removal equipment and oxygen removal method thereof

A technology for deoxidizing equipment and resin membranes, which can be used in reduction water/sewage treatment, oxidized water/sewage treatment, degassed water/sewage treatment, etc., and can solve the problems of high manufacturing cost, high operating cost and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1—5

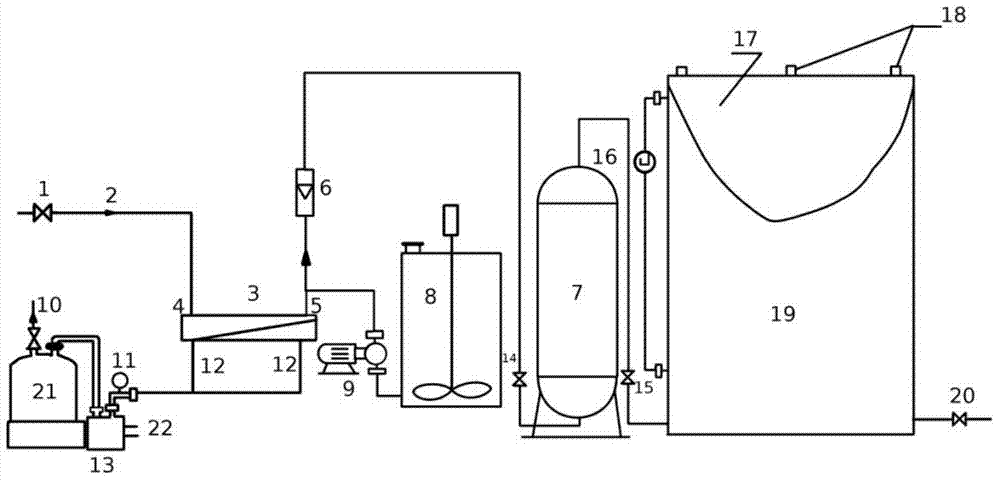

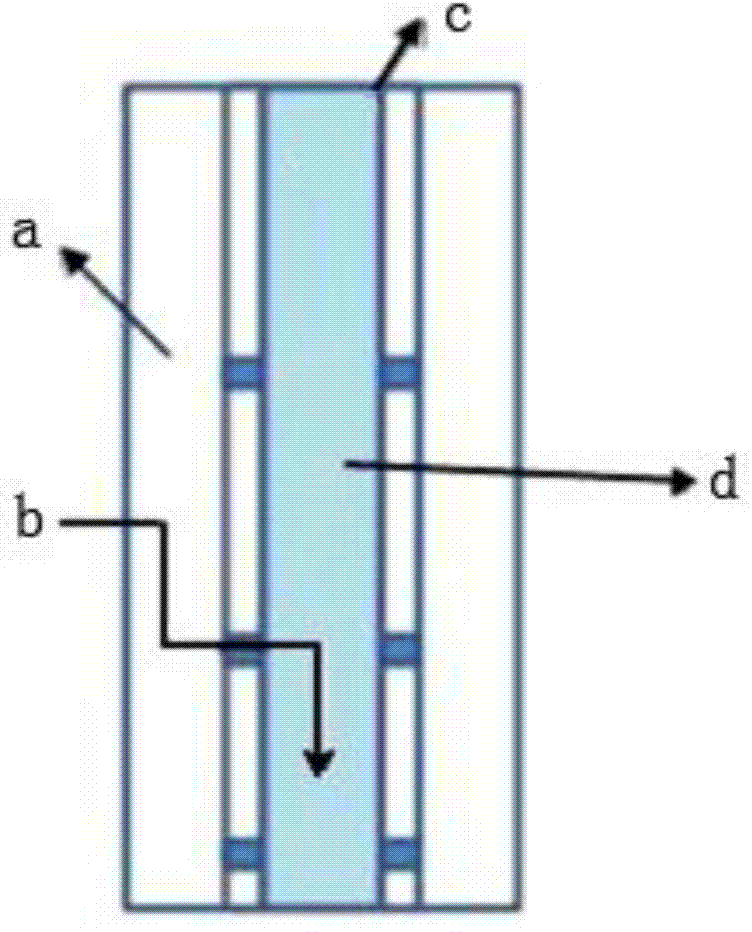

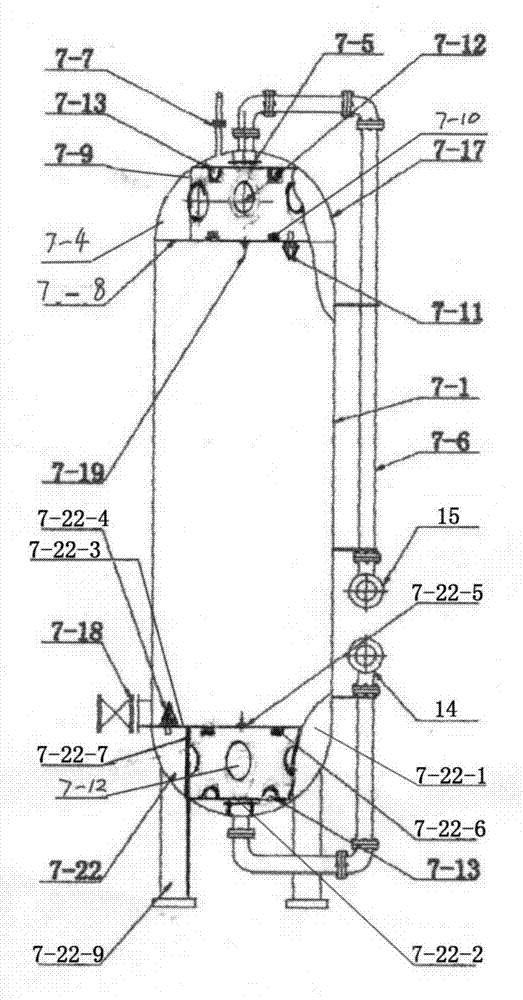

[0047] In redox resin membrane deoxygenation equipment of the present invention ( figure 1 ), where the membrane separation deaerator is 150×800mm. It consists of water inlet valve 1, membrane separation module 3, membrane separation module inlet pipe 4, membrane separation module outlet pipe 5, vacuum pump exhaust valve 10, vacuum pressure gauge 11, vacuum pump suction pipe and membrane separator air chamber suction pipe 12, The water ring vacuum pump 13 and the circulating cooling water inlet and outlet pipes 22 are composed: the water inlet valve 1 is connected to the membrane separation module 3 through the membrane separation module inlet pipe 4, and the membrane separation module outlet pipe 5 is connected to the bottom of the downstream redox resin deaerator 7 through the pipeline connected to each other, and a flow meter 6 and a floating bed resin deaerator water inlet valve 14 are arranged on the connected pipeline, the vacuum pump exhaust valve 10 is set on the top o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com