Ink slab with grinding layer and preparing method thereof

A grinding layer and inkstone technology, which is applied in the direction of inkstands, printing, office supplies, etc., can solve the problems of limited product scope, limited raw materials, low practicability, etc., and achieve the goals of improving performance, fineness, and prolonging service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

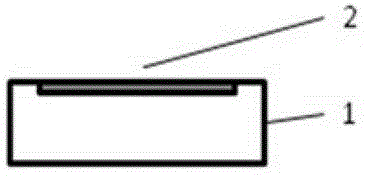

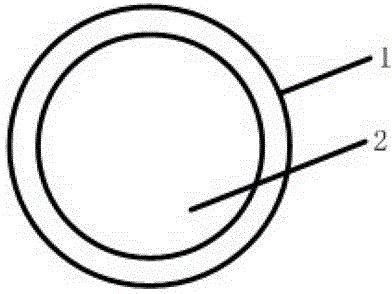

[0035] This embodiment relates to an inkstone provided with a grinding layer. The inkstone in this embodiment is round or square, such as figure 1 , 2 , 3, and 4, the grinding area of the inkstone 1 is the inkstone hall 2 of the inkstone, and the inkstone hall 2 includes a grinding layer and an inkstone hall matrix, and the grinding layer and the inkstone hall matrix are integrated, which increases firmness and prolongs the Product performance and lifespan.

[0036] This embodiment also relates to a method for preparing the aforementioned inkstone provided with an abrasive layer, comprising the following steps:

[0037] Step 1: preparing the grinding layer material;

[0038] Step 2: Prepare the matrix of the inkstone hall;

[0039] Step 3: Process the abrasive layer material on the surface of the inkstone base by thermal spraying or high-temperature firing to form an abrasive layer;

[0040] Step 4: Grinding the grinding layer.

[0041] In this embodiment, the abrasive ...

Embodiment 2

[0051] This embodiment relates to an inkstone provided with a grinding layer. The inkstone in this embodiment is round or square, such as figure 1 , 2 , 3, and 4, the grinding area of the inkstone 1 is the inkstone hall 2 of the inkstone, and the inkstone hall 2 includes a grinding layer and an inkstone hall matrix, and the grinding layer and the inkstone hall matrix are integrated, which increases firmness and prolongs the Product performance and lifespan.

[0052] This embodiment also relates to a method for preparing the aforementioned inkstone provided with an abrasive layer, comprising the following steps:

[0053] Step 1: preparing the grinding layer material;

[0054] Step 2: Prepare the matrix of the inkstone hall;

[0055] Step 3: Process the abrasive layer material on the surface of the inkstone base by thermal spraying or high-temperature firing to form an abrasive layer;

[0056] Step 4: Grinding the grinding layer.

[0057] In this embodiment, the abrasive ...

Embodiment 3

[0067] This embodiment relates to an inkstone provided with a grinding layer. The inkstone in this embodiment is round or square, such as figure 1 , 2 , 3, and 4, the grinding area of the inkstone 1 is the inkstone hall 2 of the inkstone, and the inkstone hall 2 includes a grinding layer and an inkstone hall matrix, and the grinding layer and the inkstone hall matrix are integrated, which increases firmness and prolongs the Product performance and lifespan.

[0068]This embodiment also relates to a method for preparing the aforementioned inkstone provided with an abrasive layer, comprising the following steps:

[0069] Step 1: Prepare grinding layer material;

[0070] Step 2: Prepare the matrix of the inkstone hall;

[0071] Step 3: Process the abrasive layer material on the surface of the inkstone base by thermal spraying or high-temperature firing to form an abrasive layer;

[0072] Step 4: Grinding the grinding layer.

[0073] In this embodiment, the abrasive layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com