A medium forming method for improving the formability of thick-walled metal pipe fittings

A technology for metal pipe fittings and forming performance, which is applied in the field of medium forming to improve the forming performance of thick-walled metal pipe fittings, can solve the problems of poor working environment, complicated filling process, long production cycle, etc. Make simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

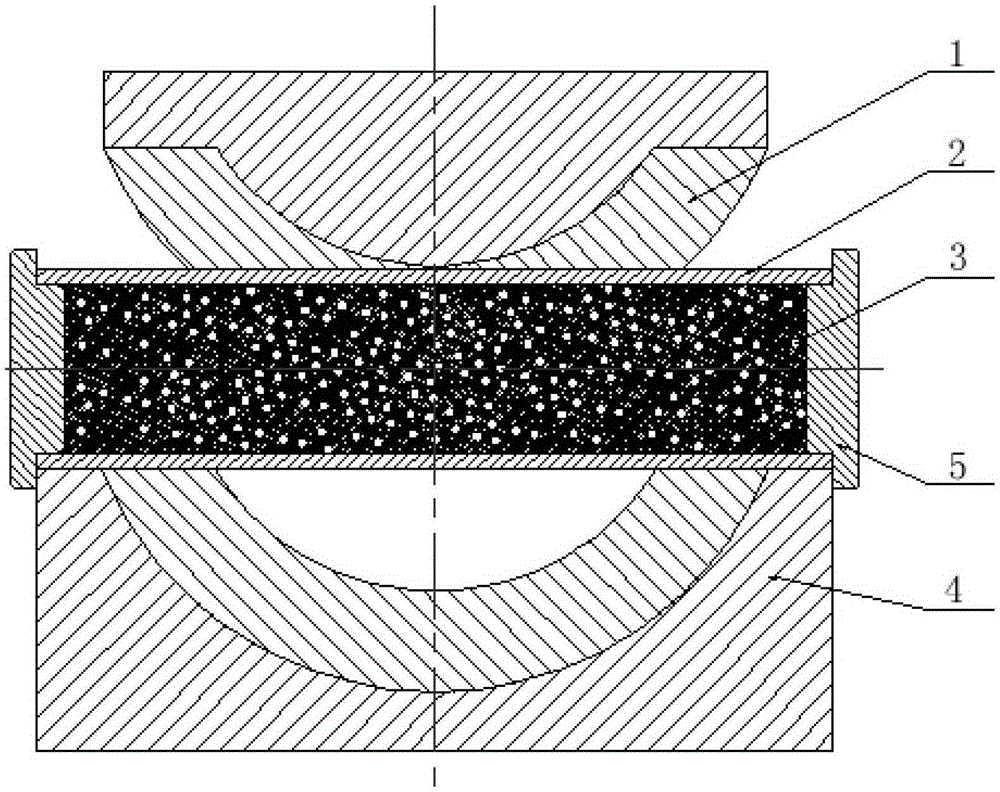

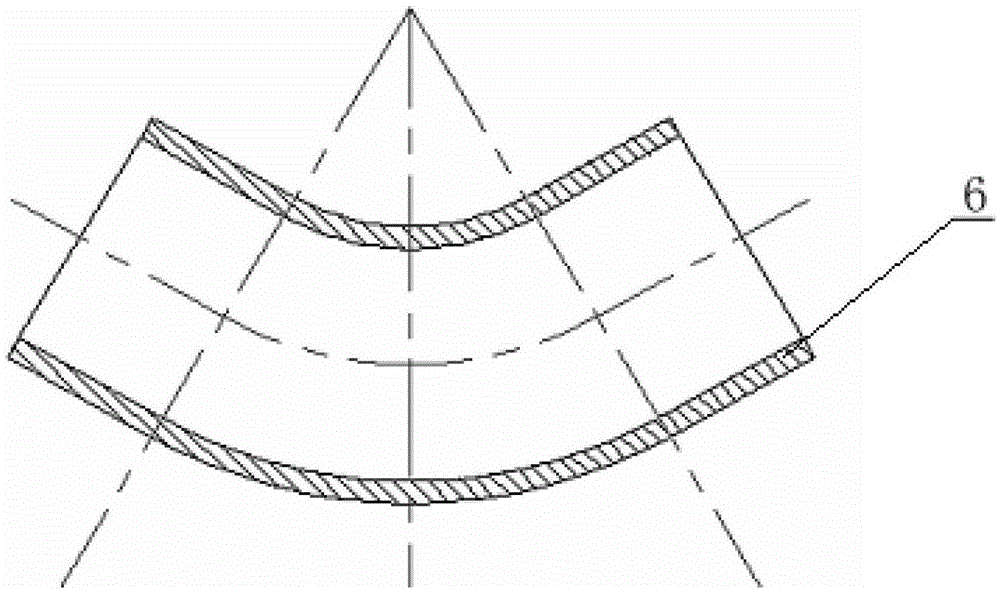

[0041] Combine below figure 1 and figure 2 This embodiment will be specifically described. This embodiment is to figure 1 The shown straight tube blank 2 is pressed and formed as figure 2 As shown in the bent pipe fitting 6, the straight pipe blank 2 in this embodiment is an aluminum alloy 6061-T651 with a yield strength of 275MPa, a melting point range of 580-650°C, a diameter of the pipe blank 2 of 76mm, and a wall thickness of 6mm.

[0042] For thick-walled metal pipes such as aluminum alloys and magnesium alloys with low strength, the requirements for the compression resistance of the composite medium 3 filled in the pipes are not high, and bismuth-based or tin-based low-melting point alloys can be used as fusible alloys. The bismuth-based low melting point alloy includes 50.6% Bi, 26.9% Pb, 12.5% Sn, and 10% Cd, with a strength of 42.1MPa and a melting point of 70°C. The tin-based low melting point alloy includes 85.4% Sn, 14.6% Bi, its strength is 85MPa, and its ...

Embodiment approach 2

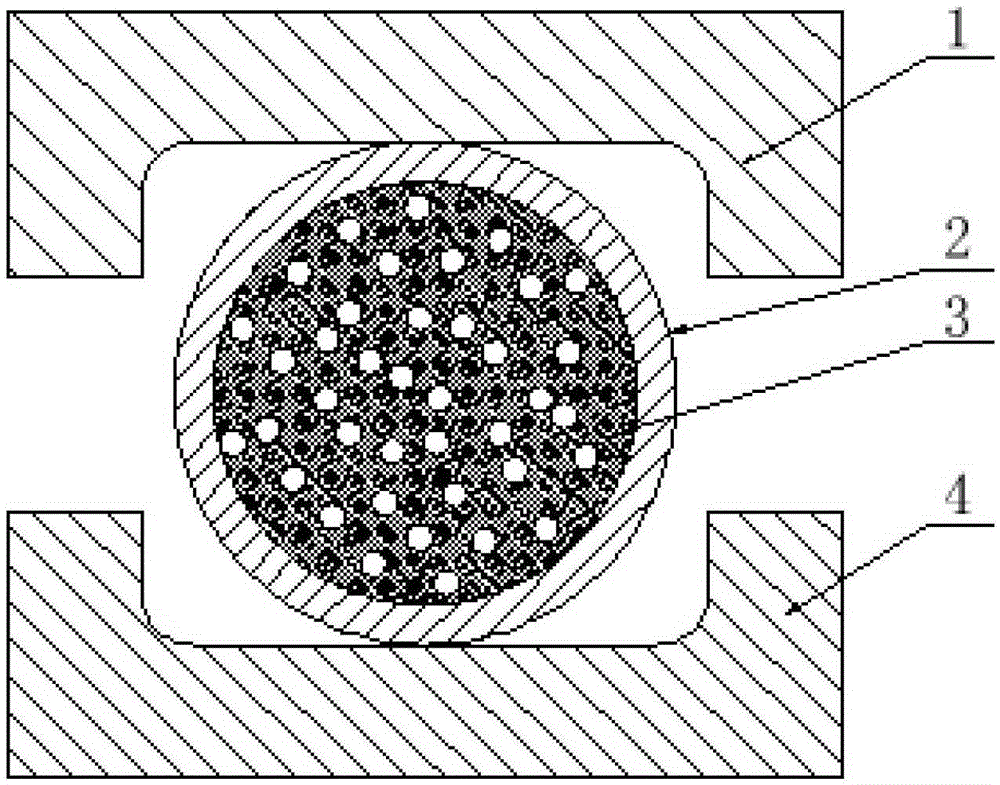

[0052] Combine below image 3 and Figure 4 This embodiment will be specifically described. In this embodiment, the 35# carbon steel pipe with high strength is used, the yield strength is 315MPa, the diameter-thickness ratio is 12.8, and the steel pipe with the diameter-thickness ratio less than 20 is called a thick-walled pipe, which requires a composite medium that can withstand relatively high pressure. .

[0053] In this embodiment, steel balls with a diameter of 4 mm are solidified with a zinc-based low-melting point alloy, and the two are uniformly mixed at a ratio of 1:1. The zinc-based low melting point alloy includes 92.4%Zn, 4%Al, 3.5%Cu, 0.1%Mg, with a strength of 194MPa and a melting point of 380°C.

[0054] This embodiment is to image 3 The shown straight tube blank 2 is pressed and formed as Figure 4 As shown in the square pipe fitting 6 , the forming device includes an upper mold cavity 1 , a lower mold cavity 4 , a tube blank 2 and a composite medium 3 ....

Embodiment approach 3

[0061] Combine below Figure 5 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the processing steps of the parts are reduced, that is, two bendings and partial flattening are completed at one time, and the manufactured pipe fitting 6 is a special-shaped cross-section pipe, and the cross-sectional shape includes: Round, square and oval. The method of the present invention is applicable to any pipe 6 whose cross-section is a closed curve profile shape. In this embodiment, the properties of the material of the tube blank 2 and the composite medium 3 filled therein are the same as those in the first embodiment. refer to Figure 5 , The forming device includes a tube blank 2, an upper mold cavity 1, a lower mold cavity 4, a composite medium 3 and a sealing plug 5.

[0062] The forming steps are as follows:

[0063] S1, uniformly mixing fusible alloy and steel ball at a ratio of 1:1 to form composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com