An Ultrasonic Friction Stir Welding Hybrid Welding System

A hybrid welding and ultrasonic stirring technology, which is applied in the field of ultrasonic friction stir welding composite welding system and ultrasonic friction stir composite welding system, can solve the problems of small ultrasonic amplitude, low ultrasonic energy density, and inability to obtain high-quality welds, etc., to achieve Large effective amplitude and strong load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

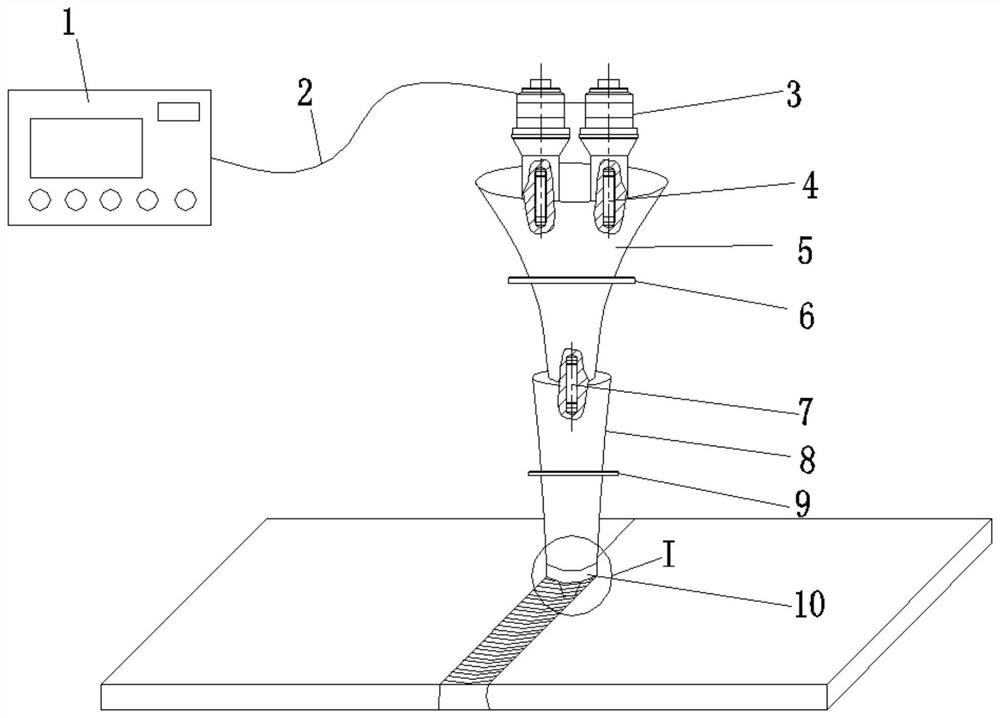

[0049] like Figures 1 to 2 As shown, an ultrasonic friction stir welding hybrid welding system includes:

[0050] A front-stage ultrasonic horn 5, the front end of the front-stage ultrasonic horn 5 is fixed with two ultrasonic transducers 3 by stud bolts I4; the ultrasonic transducer 3 is connected with the power supply 1 through the wire 2;

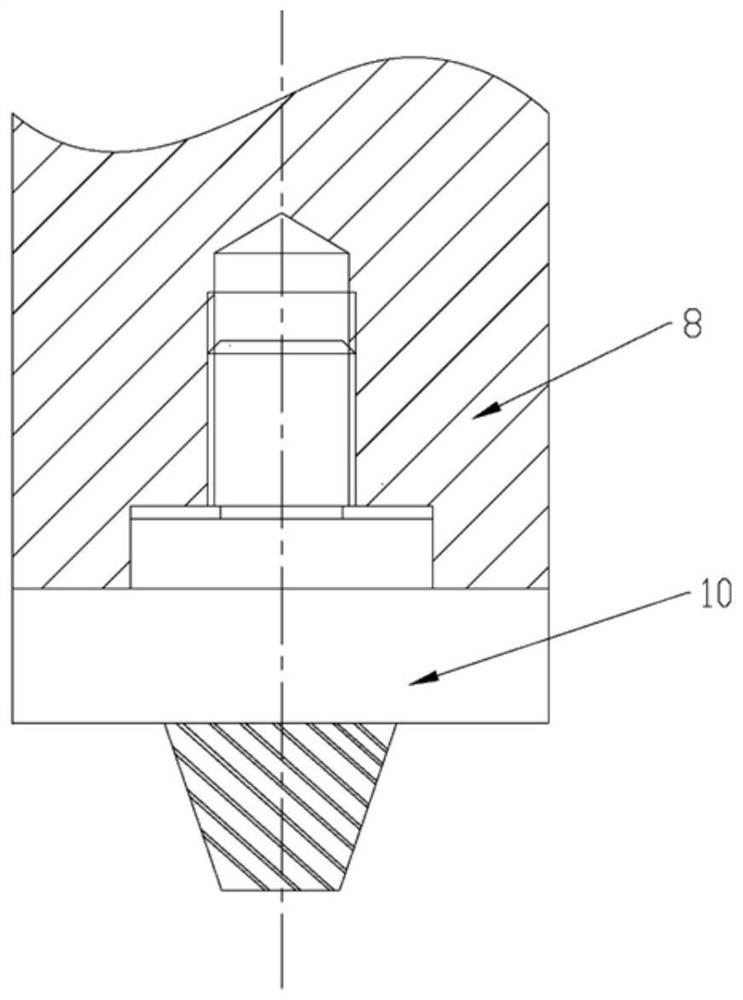

[0051] A rear-stage ultrasonic horn 8, the front end of which is tightly connected with the rear ends of all the front-stage ultrasonic horns 5 through stud bolts II7;

[0052] The stirring head 10 is fixedly connected with the rear end of the latter stage ultrasonic horn 8; the circular end face of the stirring head 10 is closely connected with the end face of the latter stage ultrasonic horn 8, and the front end of the stirring head 10 The cylindrical section of the second stage enters the shaft hole at the rear end of the ultrasonic horn 8 of the latter stage, realizes radial positioning, and is fixedly connected by bolts.

[0053]...

Embodiment 2

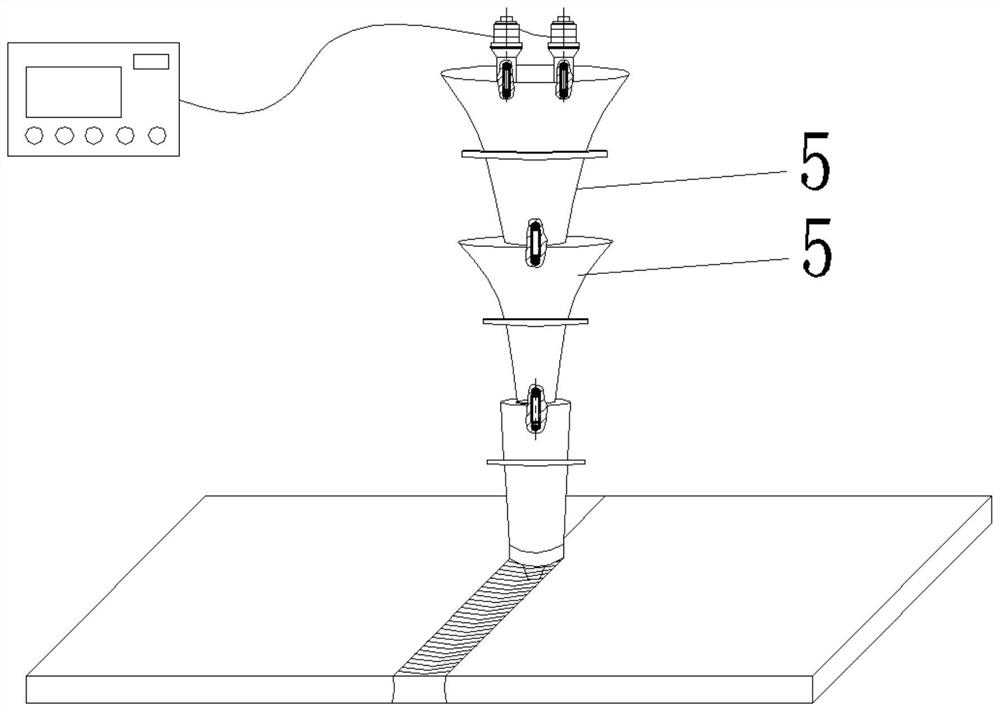

[0070] like image 3 As shown in the figure, an ultrasonic friction stir welding hybrid welding system, the difference between this embodiment and Embodiment 1 is that in this embodiment, there are two of the front-stage ultrasonic horns 5 connected in series, and all the front-end ultrasonic horns 5 are located at the front end. The front end of the front-stage ultrasonic horn 5 is fixedly connected to the ultrasonic transducer 3, and the rear end of the front-stage ultrasonic horn 5 located at the rear end is fixedly connected to the front end of the rear-stage ultrasonic horn 8. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com