Semi-submersible underwater rotary magnetized double-shaft-shoulder friction stir welding tool and mounting method

A technology of friction stir welding and underwater rotation, used in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of easy growth into coarse grains, reduction of strength and plasticity of welded joints, and achieve good welding effect. , The effect of reducing welding load and improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

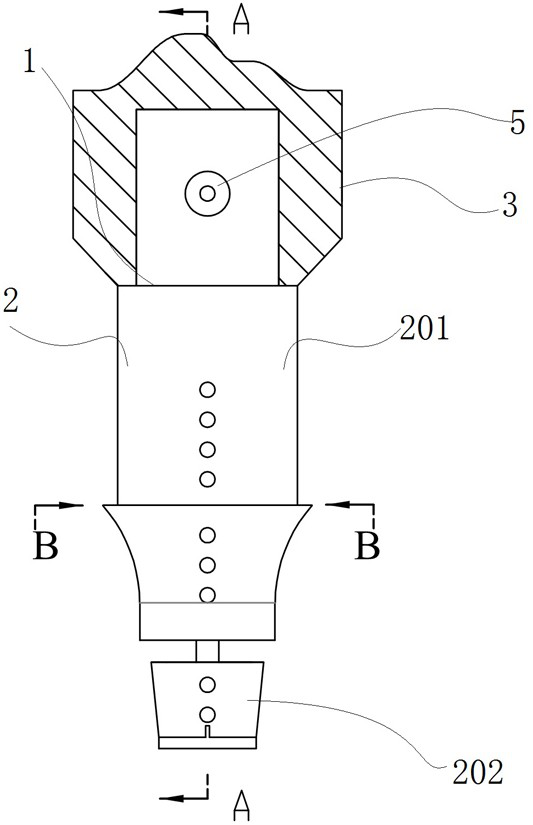

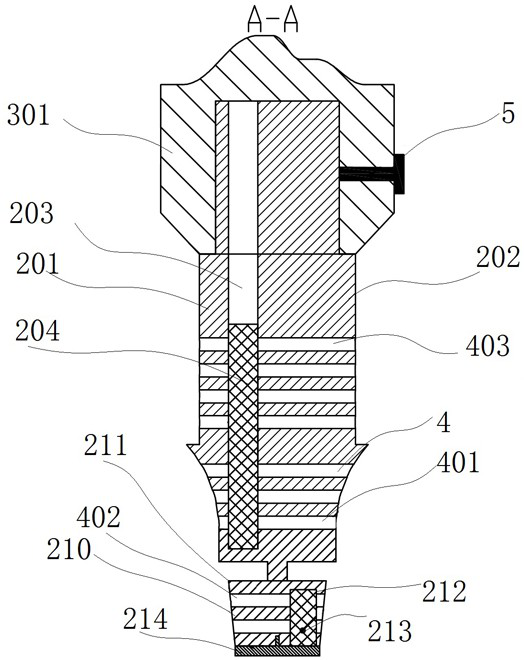

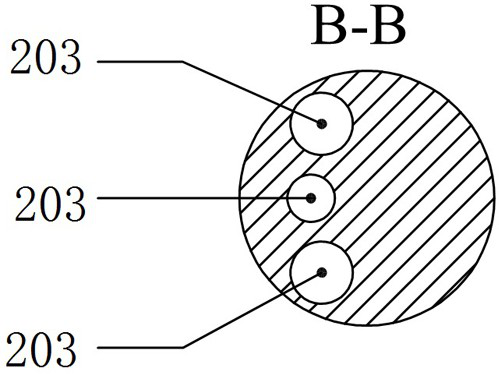

[0029] Such as figure 1 , figure 2 , image 3 As shown, a semi-submersible underwater rotary magnetization friction stir welding tool includes a stirring head body 1, and the stirring head body 1 includes a magnet bias device 2, a clamping assembly 3 and a water cooling assembly 4, and the magnet bias One end of the device 2 is sleeved in the clamping assembly 3, and the magnet bias device 2 is provided with a water-cooling assembly 4; the magnet bias device 2 includes a shaft shoulder assembly 201 on the stirring head and a shaft connected to the stirring head by a motor. The lower shoulder assembly 210 of the stirring head connected to the shoulder assembly 201 and the magnet bias device 2 greatly reduce the welding load and prolong the service life of the stirring head; when a strong rotating magnetic field is applied in the welding process, an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com