Weakly alkaline tin-base lead-free solder composite plating solution and application thereof

A technology of composite plating solution and lead-free solder, which is applied in the direction of electrolytic coating, coating, etc., can solve the problems of failure of plating solution and failure to obtain tin composite coating, and achieve the effects of low corrosion, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

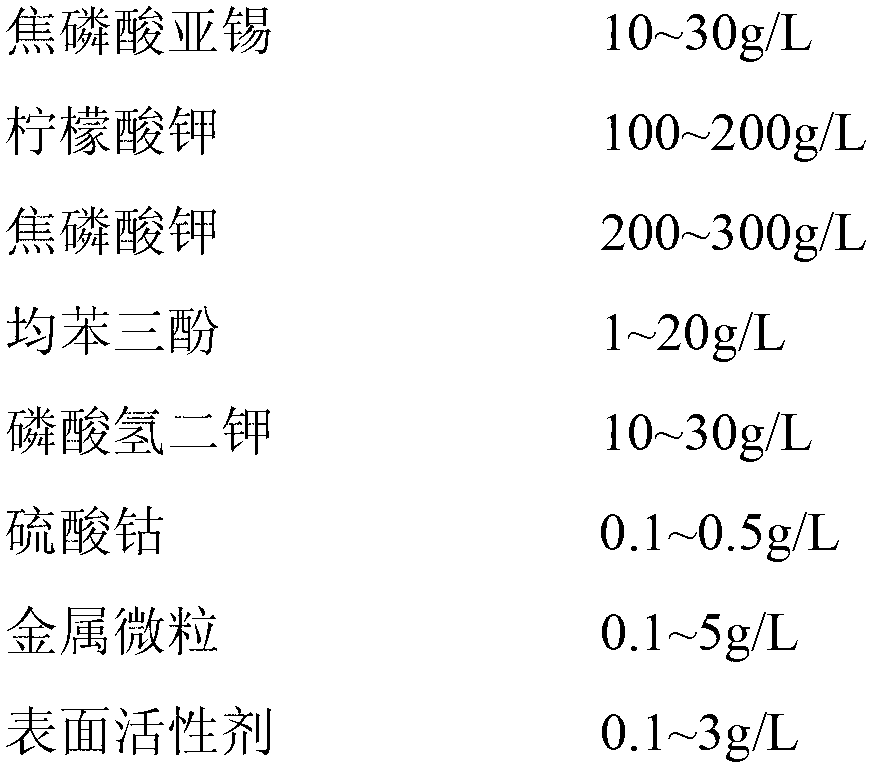

Embodiment 1

[0036]

[0037]

[0038] Solution movement mode Magnetic stirring

[0039] According to this electroplating process, a 99.3wt%Sn-0.7wt%Cu composite coating is obtained, the coating is dense, the copper particles are evenly distributed, and the porosity of the coating is 0.58 / cm 2 , the measured melting point of the coating is 230.8°C, which is slightly higher than the melting point of 99.3wt%Sn-0.7wt%Cu bulk solder, and is welded to the nickel substrate after electroplating a 50μm thick 99.3wt%Sn-0.7wt%Cu composite coating on the copper substrate , Good adhesion after welding.

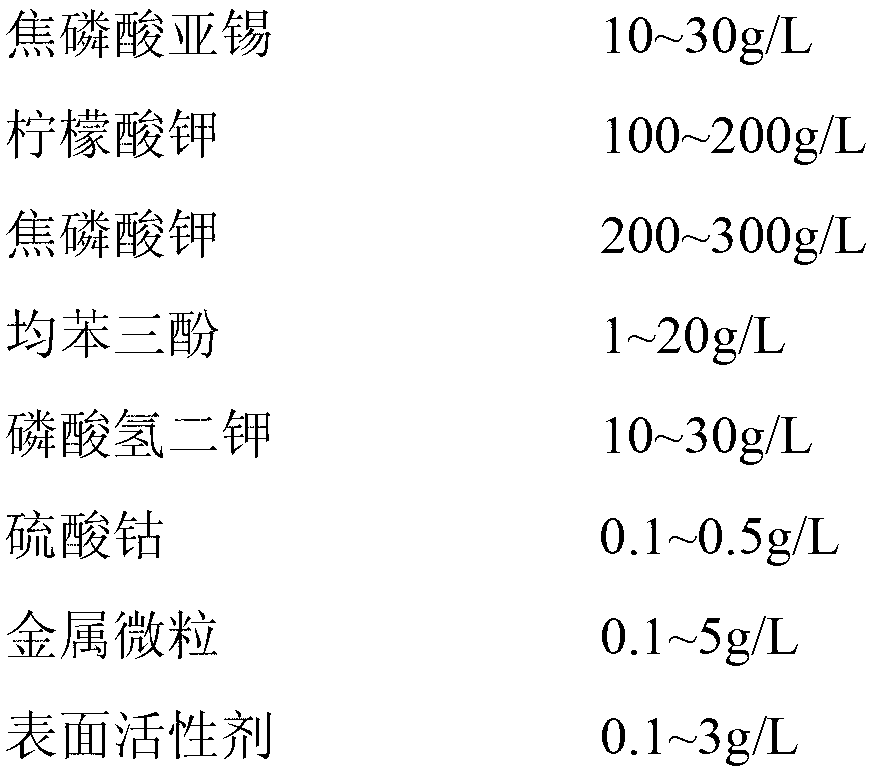

Embodiment 2

[0041]

[0042] Solution Movement Mode Ultrasonic Vibration

[0043] According to this electroplating process, a 99wt%Sn-0.3wt%Ag-0.7wt%Cu composite coating is obtained, the coating is dense, the silver and copper particles are evenly distributed, and the porosity of the coating is 1.28 / cm 2 , the melting point of the measured coating is 228.6 ° C, slightly lower than the melting point of 99wt%Sn-0.3wt%Ag-0.7wt%Cu bulk solder, and 99wt%Sn-0.3wt%Ag-0.7wt%Cu is electroplated on a copper substrate with a thickness of 50 μm After the composite coating is welded with the nickel substrate, the bonding force is good after welding.

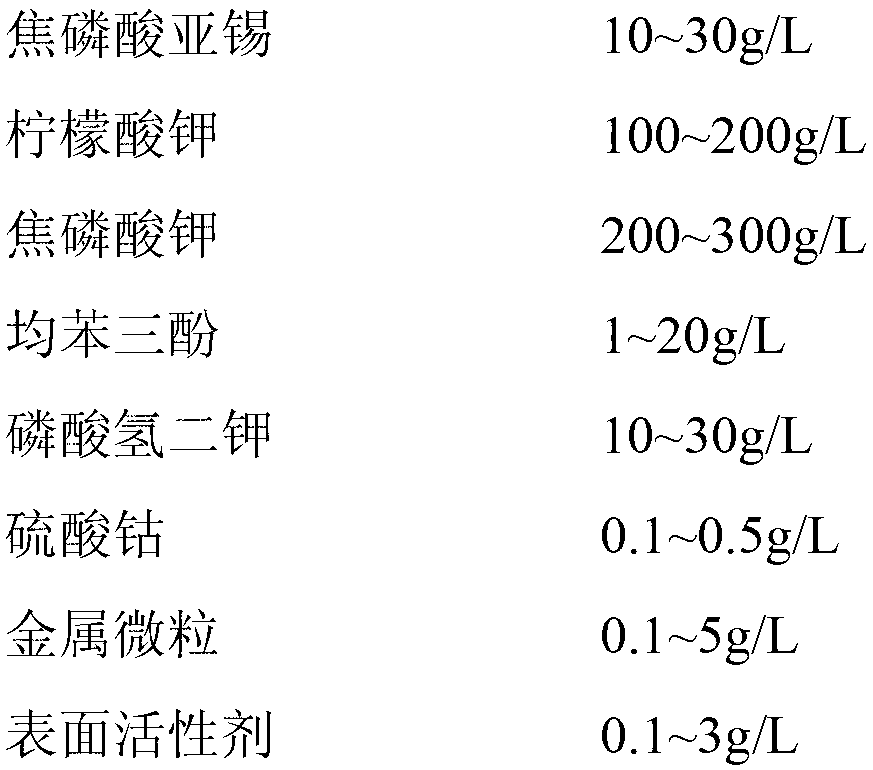

Embodiment 3

[0045]

[0046] Solution Movement Mode Ultrasonic Vibration

[0047] According to this electroplating process, a 95wt%Sn-4wt%Zn-0.5wt%Al-0.5wt%Ag composite coating is obtained, the coating is dense, the metal particles are evenly distributed, and the porosity of the coating is 0.87 / cm 2 , the melting point of the coating was measured to be 209.8°C, and the composite coating of 95wt%Sn-4wt%Zn-0.5wt%Al-0.5wt%Ag was electroplated on the copper substrate with a thickness of 50 μm and then welded to the aluminum substrate, and the bonding was good after welding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com