Asymmetric polyimide film for separating methyl cyclopentadiene and cyclopentadiene

A technology of methylcyclopentadiene and polyimide membrane, which is applied in the fields of semi-permeable membrane separation, membrane purification/separation, membrane technology, etc., and can solve the problem of complex vacuum distillation process, complex process flow and large equipment investment etc. to achieve the effect of good selective permeability, high separation rate and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

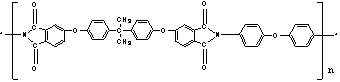

[0035] Dissolve an appropriate amount of dried 4,4-diaminodiphenyl ether (ODA) in N, N-dimethylacetamide (DMAc), stir to fully dissolve the ODA, and add an appropriate amount of bisphenol-A diether in three batches Dianhydride (BPADA), N 2Stir under protection, slowly add equimolar equivalents of acetic anhydride and triethylamine dropwise, and raise the temperature to 60 °C for chemical imidization, then pour the mixture quickly into stirring ethanol to precipitate a polymer, wash with deionized water Afterwards, place in a vacuum oven to prepare polyimide solids.

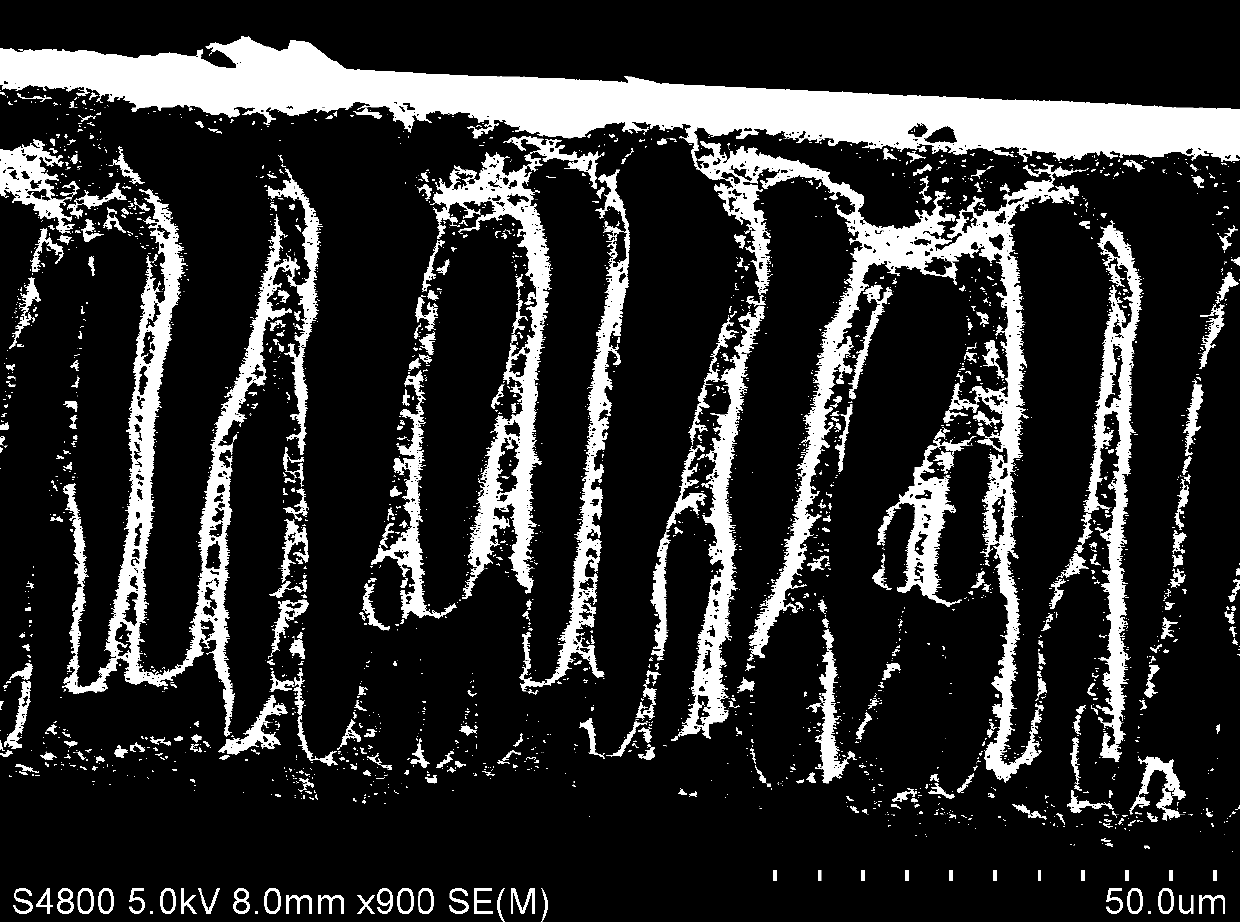

[0036] The above-mentioned polyimide solid is dissolved in N-methylpyrrolidone (NMP) according to a certain mass ratio, N 2 Add acetone with a mass ratio of 15% under protection, oscillate to dissolve, filter the casting solution through a stainless steel wire mesh to remove impurities, let it stand to remove air bubbles, and evenly drool on a glass plate, control different solvent volatilization times, scrape to...

Embodiment 2

[0041] Take the polyimide solids prepared by different amounts of example 1 according to the polyimide solid content as 16%, 17%, 18%, and 20%, and dissolve them in N-methylpyrrolidone (NMP), N 2 Add acetone with a mass ratio of 15% under protection, oscillate to dissolve, filter the casting film solution through stainless steel wire mesh to remove impurities, let it stand to remove air bubbles, and evenly drool on a glass plate. The solvent volatilization time is 60s, scrape to form a film, and place Precipitate in a deionized hydrogel bath at 20 ℃, soak in deionized water and glycerin to replace the solvent, prepare polyimide asymmetric membranes with different solid contents, and use a membrane pervaporation performance evaluation device to measure its separation performance. Liquid is C 5 Fractional distillation products (the mass ratio of methylcyclopentadiene to cyclopentadiene after thermal depolymerization is about 80:20), and the through-test material is analyzed by t...

Embodiment 3

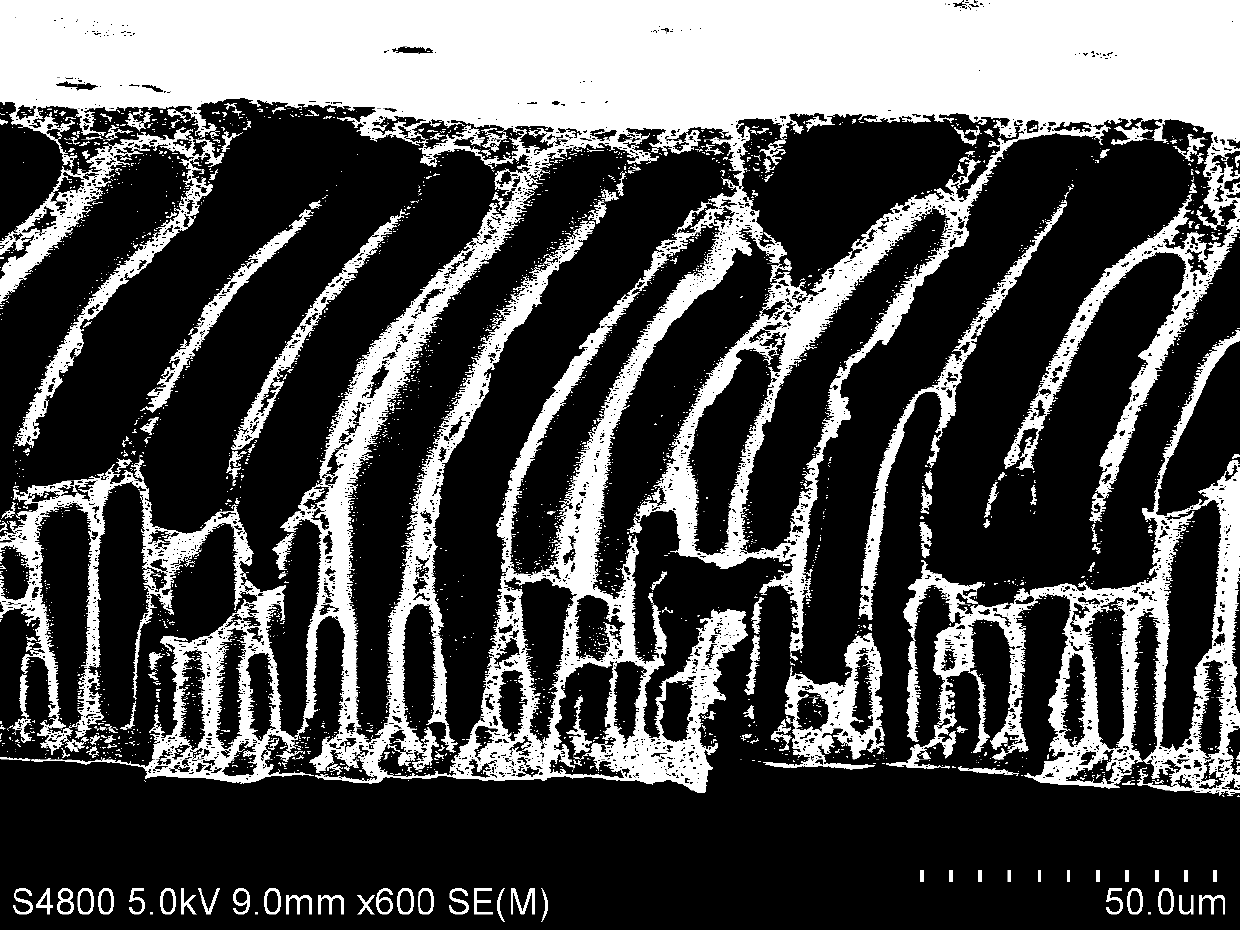

[0045] Take by weighing the polyimide solid prepared by an appropriate amount of example one, dissolve in N-methylpyrrolidone (NMP), N 2 Add acetone with a mass ratio of 15% under protection, oscillate to dissolve, filter the casting film solution through stainless steel wire mesh to remove impurities, let it stand to remove air bubbles, and evenly drool on a glass plate. The solvent volatilization time is 60s, scrape to form a film, and place Phase inversion precipitation in different gel media at 20 ℃, respectively soaked in deionized water and glycerin to replace the solvent, prepared polyimide asymmetric membranes formed under different gel media conditions, and measured their properties using a membrane pervaporation performance evaluation device Separation performance, feed liquid is C 5 Fractional distillation products (the mass ratio of methylcyclopentadiene to cyclopentadiene after thermal depolymerization is about 80:20), and the through-test material is analyzed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com