High voltage and ultrahigh voltage flexible direct current transmission optical fiber composite extrusion insulation submarine cable

A flexible DC power transmission and optical fiber composite technology, which is applied in the direction of submarine cables, power cables, and power cables with shielding layers/conductive layers, etc., can solve problems such as pollution, prevent environmental pollution, reduce cable costs, and prevent heavy metal pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

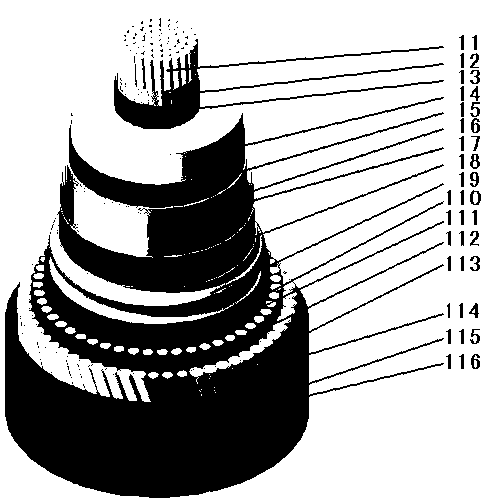

[0020] This embodiment is a rated voltage ±320 kV flexible direct current transmission optical fiber compound extruded insulated submarine cable.

[0021] (1) The water-blocking conductor 11 is made of pure aluminum with a cross-sectional area of 1400 mm 2 , using a stranded circular compact conductor structure or a split conductor structure, and the gap between the conductors is filled with water-blocking materials;

[0022] (2) Semi-conductive Tetoron wrapping tape 12, thickness 0.18 mm;

[0023] (3) Semi-conductive inner shield 13 with a thickness of 1.5 mm;

[0024] (4) The extruded insulating layer 14 is an ultra-clean PE cross-linked material added with a space charge inhibitor, the working temperature is 90°C, the dielectric constant is 2.3, the DC breakdown field strength is greater than 45 kV / mm, and the insulating layer thickness (22~ 24) mm; the mixture of ultra-clean PE crosslinking material and space charge inhibitor is made by melt mixing method;

[0025] (5...

Embodiment 2

[0038] This embodiment is a rated voltage ±200 kV flexible direct current transmission optical fiber compound extruded insulation submarine cable.

[0039] (1) Water-blocking conductor 11, made of aluminum alloy or copper for cable conductors, with a cross-sectional area of 1000 mm 2 , using a twisted circular compact conductor structure, the gap between the conductors is filled with water-blocking materials;

[0040] (2) Semi-conductive Tetoron wrapping tape 12, thickness 0.18 mm;

[0041] (3) Semi-conductive inner shield 13 with a thickness of 1.5 mm;

[0042] (4) The extruded insulating layer 14 is an ultra-clean PE cross-linked material added with a space charge inhibitor, the working temperature is 90°C, the dielectric constant is 2.3, the DC breakdown field strength is greater than 45 kV / mm, and the insulating layer thickness (12~ 14) mm; the mixture of ultra-clean PE crosslinking material and space charge inhibitor is made by melt mixing method;

[0043] (5) Semi-c...

Embodiment 3

[0056] This embodiment is a rated voltage ±160 kV flexible direct current transmission optical fiber compound extruded insulation submarine cable.

[0057] (1) Water-blocking conductor 11, made of copper, with a cross-sectional area of 500 mm 2 , using a twisted circular compact conductor structure, the gap between the conductors is filled with water-blocking materials;

[0058] (2) Semi-conductive nylon wrapping tape 12, thickness 0.1 mm;

[0059] (3) Semi-conductive inner shield 13, thickness (1.2-1.5) mm;

[0060] (4) The extruded insulating layer 14 is an ultra-clean PE crosslinking material added with a space charge inhibitor, the working temperature is 90°C, the dielectric constant is 2.3, the DC breakdown field strength is greater than 45 kV / mm, and the insulating layer thickness (11~ 13) mm; the mixture of ultra-clean PE crosslinking material and space charge inhibitor is made by melt mixing method;

[0061] (5) Semi-conductive outer shield 15, thickness 1 mm;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com