Shaft motion control method based on double feedbacks of motor and machine tool location

A motion control, dual feedback technology, applied in the direction of electrical program control, digital control, etc., can solve the problems of accelerated wear of the machine tool transmission, unstable speed of the servo motor, and inability to apply well, to avoid abnormal axis motion or even speeding. , high speed smoothness, avoid unstable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

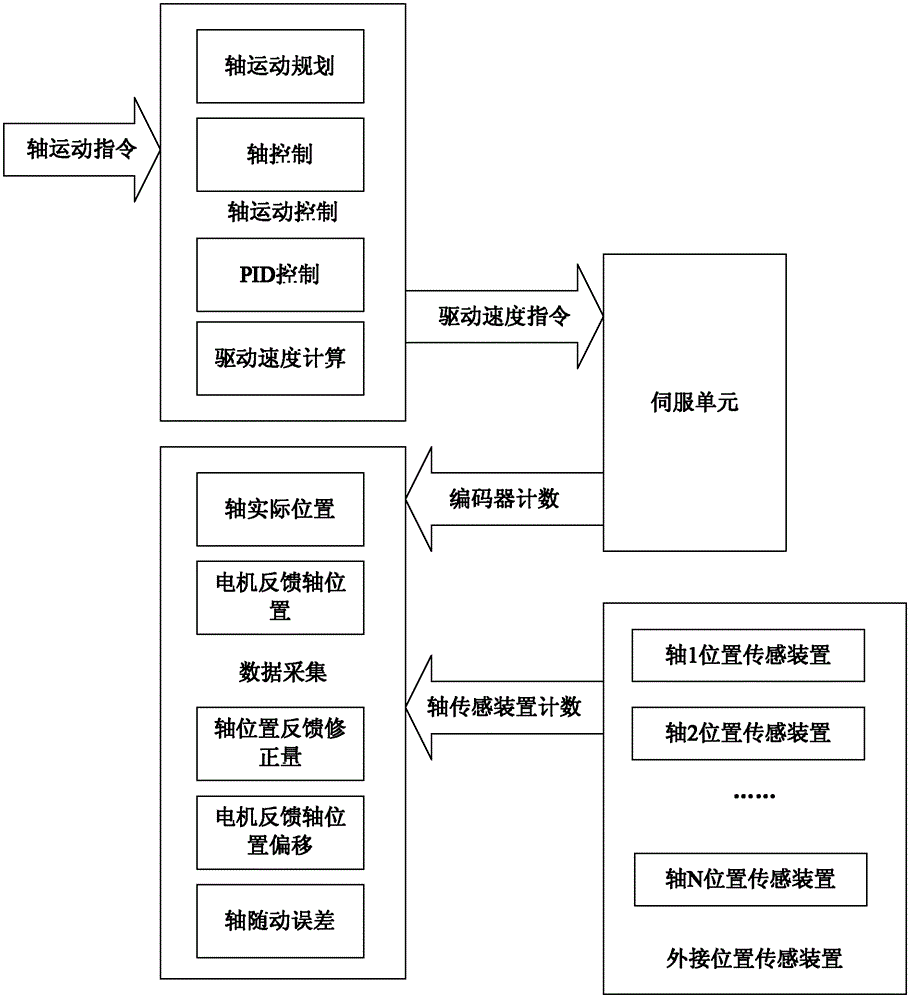

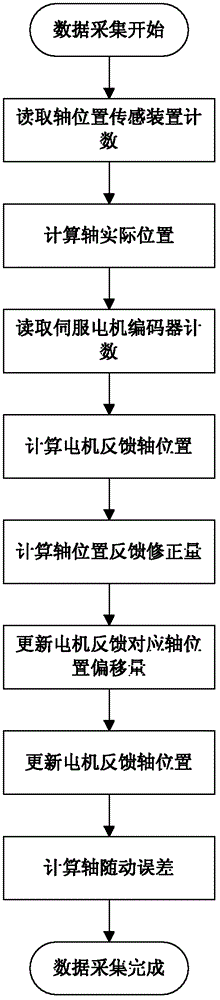

[0025] Axis motion control includes three parts: axis motion planning, axis control and PID control. Among them, the axis motion planning adopts the axis dynamic planning processing method of dual position feedback, and the axis motion planning is carried out for the axis motion command to form the axis speed setting value in the processing process. The control realizes the smooth rotation of the servo motor in the shaft transmission device.

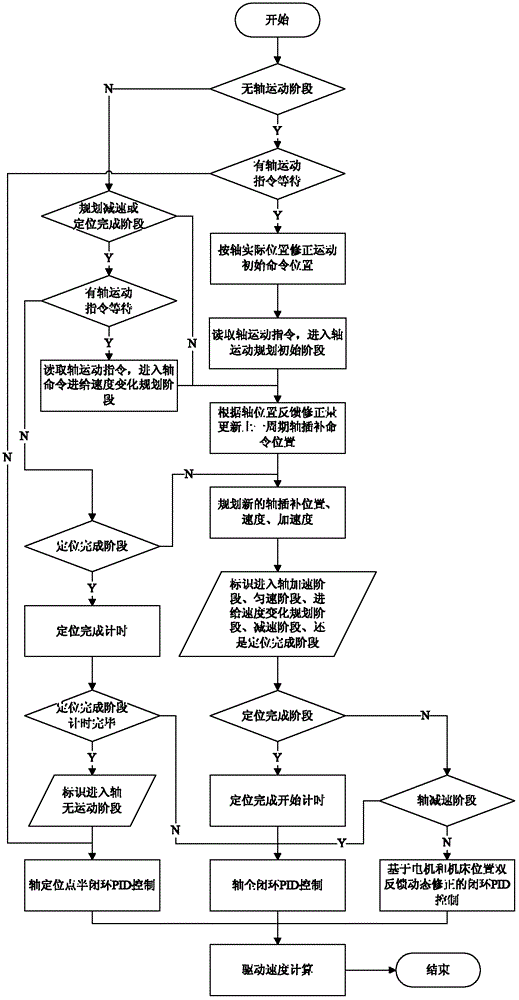

[0026] The axis motion planning includes 6 stages: 1) planning acceleration stage; 2) planning constant speed stage; 3) planning deceleration stage; 4) axis command feed speed change planning stage; 5) positioning completion stage; exercise phase. For different motion planning stages, the axis motion control method based on dual feedback of motor and machine tool position can be divided into different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com