Process for treating high-arsenic and high cadmium waste acid by using three-stage lime-ferric salt method

A treatment process, high arsenic and high cadmium technology, applied in the direction of neutralized water/sewage treatment, oxidized water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the problem of high cadmium content in the treatment object, and the experimental design has not reached industrial application level and other issues, to achieve considerable economic benefits, reduce the amount of slag produced, and reduce toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

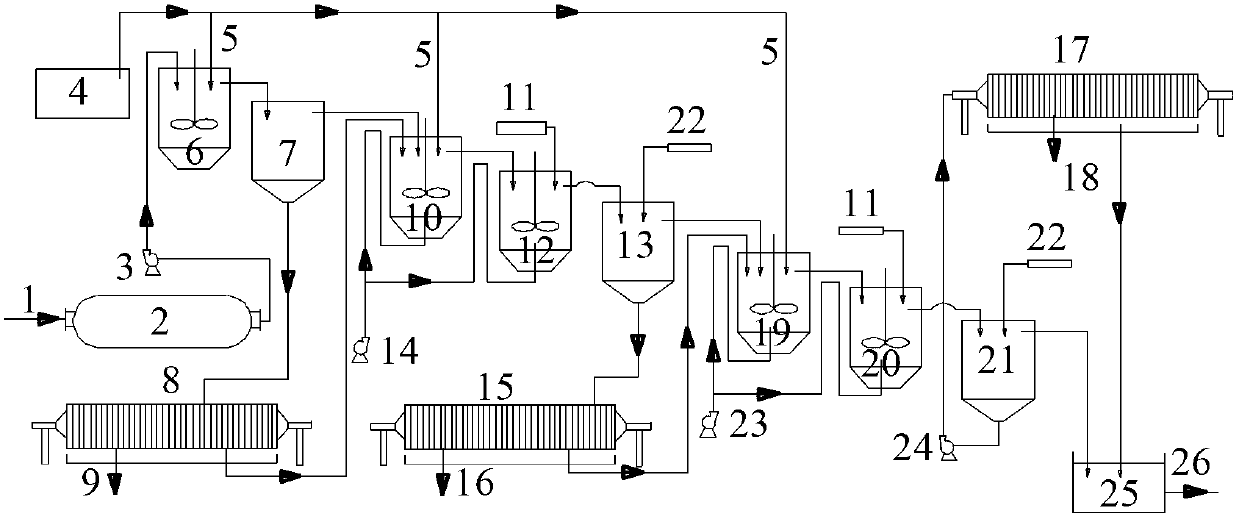

Method used

Image

Examples

Embodiment 1

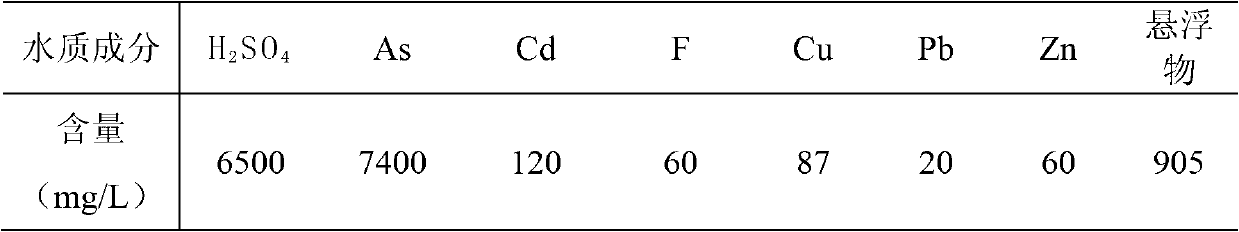

[0048] Treatment object: the sewage acid wastewater discharged from the sulfuric acid workshop of the smelter of Daye Nonferrous Metal Mining Co., Ltd., with a treatment capacity of 30m 3 .

[0049] Influent water quality table:

[0050]

[0051] The processing steps are as follows:

[0052] (1) The first gypsum manufacturing section: Put lime milk into the dirty acid, adjust the pH of the dirty acid to 2, remove most of the sulfuric acid in the dirty acid through neutralization reaction, react for 1 hour, and form calcium sulfate precipitation, settle for 1 hour Solid-liquid separation to produce gypsum, as a by-product, has passed the appraisal of Wuhan Mineral Resources Supervision and Testing Center of the Ministry of Land and Resources, and its quality is better than GB / T5483-2008 gypsum standard, which can be used as raw material for cement and other industries;

[0053] (2) The second stage neutralizes and oxidizes the arsenic precipitation section: Add milk of lim...

Embodiment 2

[0062] Treatment object: the sewage acid wastewater discharged from the sulfuric acid workshop of the smelter of Daye Nonferrous Metal Mining Co., Ltd., with a treatment capacity of 30m 3 .

[0063] Influent water quality table:

[0064]

[0065] The processing steps are as follows:

[0066] (1) The first gypsum manufacturing section: Put lime milk into the dirty acid, adjust the pH of the dirty acid to 2, remove most of the sulfuric acid in the dirty acid through neutralization reaction, react for 1 hour, and form calcium sulfate precipitation, settle for 1 hour Solid-liquid separation to produce gypsum, as a by-product, has passed the appraisal of Wuhan Mineral Resources Supervision and Testing Center of the Ministry of Land and Resources, and its quality is better than GB / T5483-2008 gypsum standard, which can be used as raw material for cement and other industries;

[0067] (2) The second stage neutralizes and oxidizes the arsenic precipitation section: Add milk of lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com