A preparation method of fish egg glycoprotein with anti-osteoporosis effect

A technology for osteoporosis and glycoproteins, applied in food preparation, hydrolyzed protein components, applications, etc., to achieve strong anti-osteoporosis activity, no environmental pollution, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

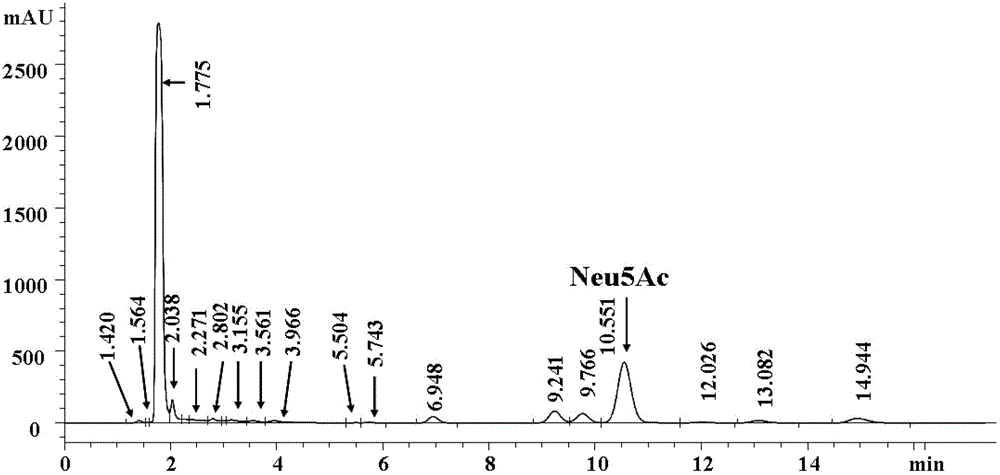

Image

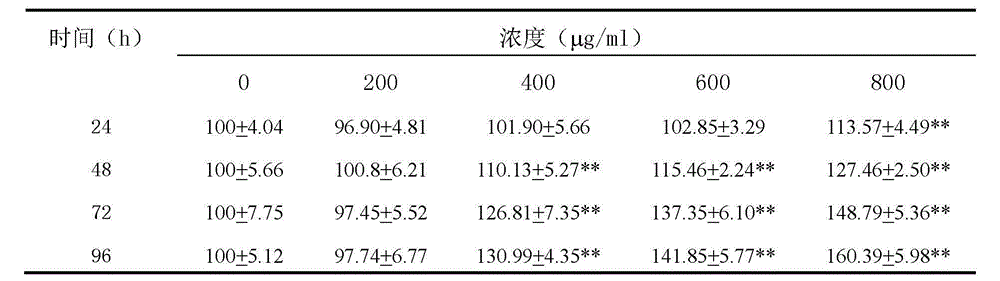

Examples

Embodiment 1

[0018] Take 2.0 kg of fresh or thawed crucian carp roe at room temperature, remove impurities, wash 3 times, colloid mill homogenate, and freeze-dry, add 3L of 95% ethanol to degrease for 15 hours, and change ethanol 4 times during this period. Centrifuge at 3500 rpm for 10 minutes, remove the supernatant, and the precipitate is defatted roe protein. Freeze-dry the defatted fish egg protein, add 6L of distilled water and preheat to 50°C. Under constant temperature stirring, add 3g of neutral protease and 3g of alkaline protease for hydrolysis for 5 hours, and the pH is 7.0. Then inactivate the enzyme activity at 100°C for 7 minutes. The enzymatic solution was cooled to room temperature and centrifuged at 5000 rpm for 5 min. The supernatant was taken, subjected to ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 10KD, and the filtrate was freeze-dried to obtain a fish egg glycopeptide sample.

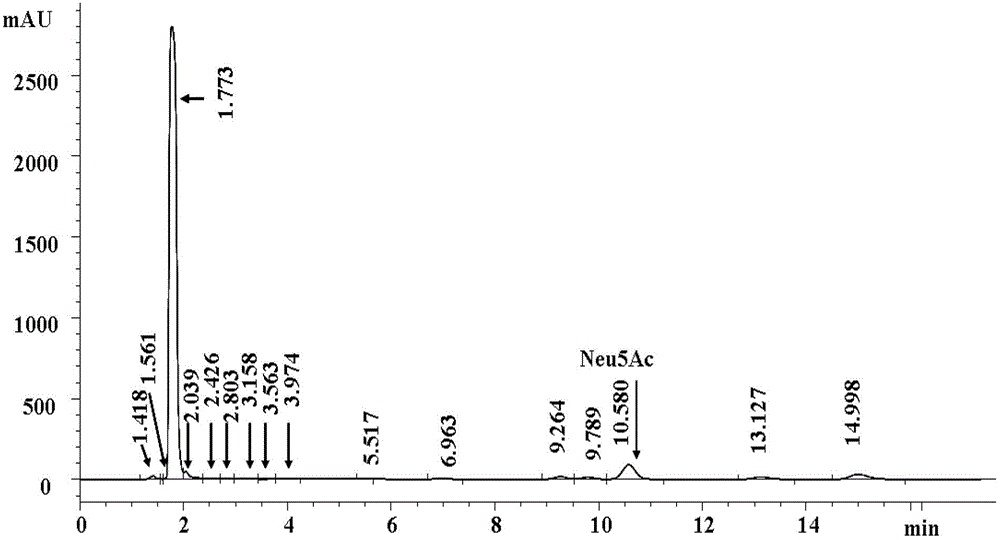

Embodiment 2

[0020] Take 2.0 kg of fresh cod roe or thawed at room temperature, remove impurities, wash 3 times, colloid mill homogenate, freeze-dry, add 3L of 95% ethanol to degrease for 18 hours, and change ethanol 3 times during this period. Centrifuge at 3500 rpm for 10 minutes, remove the supernatant, and the precipitate is defatted roe protein. Freeze-dry the defatted fish egg protein, add 6L of distilled water and preheat to 50°C. Under constant temperature stirring, add 4g of neutral protease and 4g of alkaline protease for hydrolysis for 4 hours, and the pH is 7.0. Then inactivate the enzyme activity at 100°C for 7 minutes. The enzymatic solution was cooled to room temperature and centrifuged at 5000 rpm for 5 min. The supernatant was taken, subjected to ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 10KD, and the filtrate was freeze-dried to obtain a fish egg glycopeptide sample.

[0021] The 95% ethanol degreasing 15h described in the prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com