Filling glue for filling asphalt pavement crack and preparation method thereof

A technology of asphalt pavement and caulking adhesive, which is applied in the direction of roads, roads, adhesives, etc., can solve the problems of oily surface repairs, etc., and achieve the effects of improving leveling, shortening traffic opening time, and excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] By weight, put 100 parts of 106 silicone rubber emulsion, 15 parts of barium sulfate and 1.5 parts of carbon black into the mixer, stir at 80°C at a speed of 1000rpm for 90min, vacuumize and cool at 60°C, and then add 40 parts of 107 silicone Rubber emulsion, 0.1 part of dibutyltin dilaurate, 30 parts of MQ silicone resin, and continue vacuuming for 50 minutes, and after mixing evenly, component A is prepared; 2 parts of ethyl orthosilicate, 2 parts of γ-aminopropyl tri Mix and stir Ethoxysilane and 1 part of Methyltributanoximinosilane to form Part B. When using, by weight, according to the ratio of component B: component A: 2.5: 100, slowly add component B to component A which is stirred at a slow speed, then stir at a speed of 300rpm for 20 minutes, and prepare after mixing evenly A caulking compound for repairing cracks in asphalt pavements.

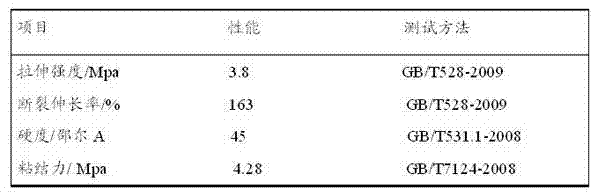

[0037] Place the obtained gap filler on the polytetrafluoroethylene mold for 5.5 hours to completely cure to form a...

Embodiment 2

[0041] In terms of weight, put 100 parts of 106 silicone rubber emulsion, 25 parts of calcium carbonate and 3 parts of carbon black into the mixer, stir at 80°C at a speed of 1100rpm for 90min, vacuumize and cool at 60°C, and then add 30 parts of 107 silicone Rubber emulsion and 10 parts of polyurethane 101 component A, 0.2 parts of tin maleate, 35 parts of MQ silicone resin, and continue vacuuming for 50 minutes, and after mixing evenly, component A is prepared; 3 parts of ethyl orthosilicate, 2 parts Mix and stir 1 part of anilinomethyltriethoxysilane and 1 part of methyltributylketoximosilane to form component B. When in use, by weight, according to the ratio of component B: component A 3.5: 100, slowly add component B to component A which is stirred at a slow speed, then stir at a speed of 300rpm for 20 minutes, and prepare after mixing evenly A caulking compound for repairing cracks in asphalt pavements.

[0042] Place the obtained gap filler on the polytetrafluo...

Embodiment 3

[0046] By weight, put 100 parts of 106 silicone rubber emulsion, 20 parts of barium sulfate, 10 parts of calcium carbonate and 3 parts of carbon black into the mixer, stir at 1100rpm at 80°C for 90min, evacuate and cool at 60°C, and then add 40 107 parts of silicone rubber emulsion, 15 parts of polyurethane 101 component A, 0.2 parts of tin maleate, 40 parts of MQ silicone resin, and continue vacuuming for 50 minutes, and make A component after mixing uniformly; 4 parts of orthosilicic acid Ethyl ester, 3 parts of γ-glycidyl etheroxypropyl trimethoxysilane and 1 part of methyl tributanoximino silane were mixed and stirred to form component B. When using, by weight, according to the ratio of component B: component A 4:100, slowly add component B to component A which is stirred at a slow speed, then stir at a speed of 300rpm for 20min, and prepare after mixing evenly A caulking compound for repairing cracks in asphalt pavements.

[0047] Place the obtained gap filler on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com