Glass fiber reinforced hydrolysis-resistant nylon pa6/pa66 composite material and preparation method thereof

A technology of glass fiber and PA66, which is applied in the field of preparation of glass fiber reinforced hydrolysis-resistant nylon PA6/PA66 composite materials, which can solve the problems of high cost and large amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

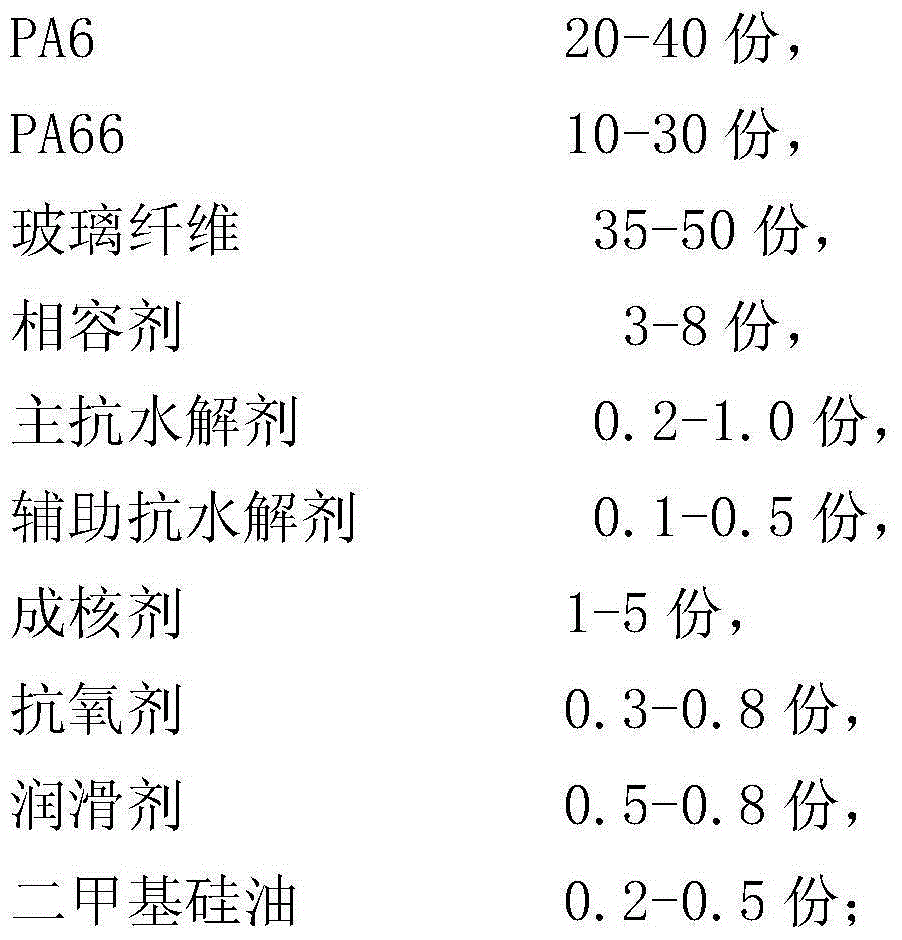

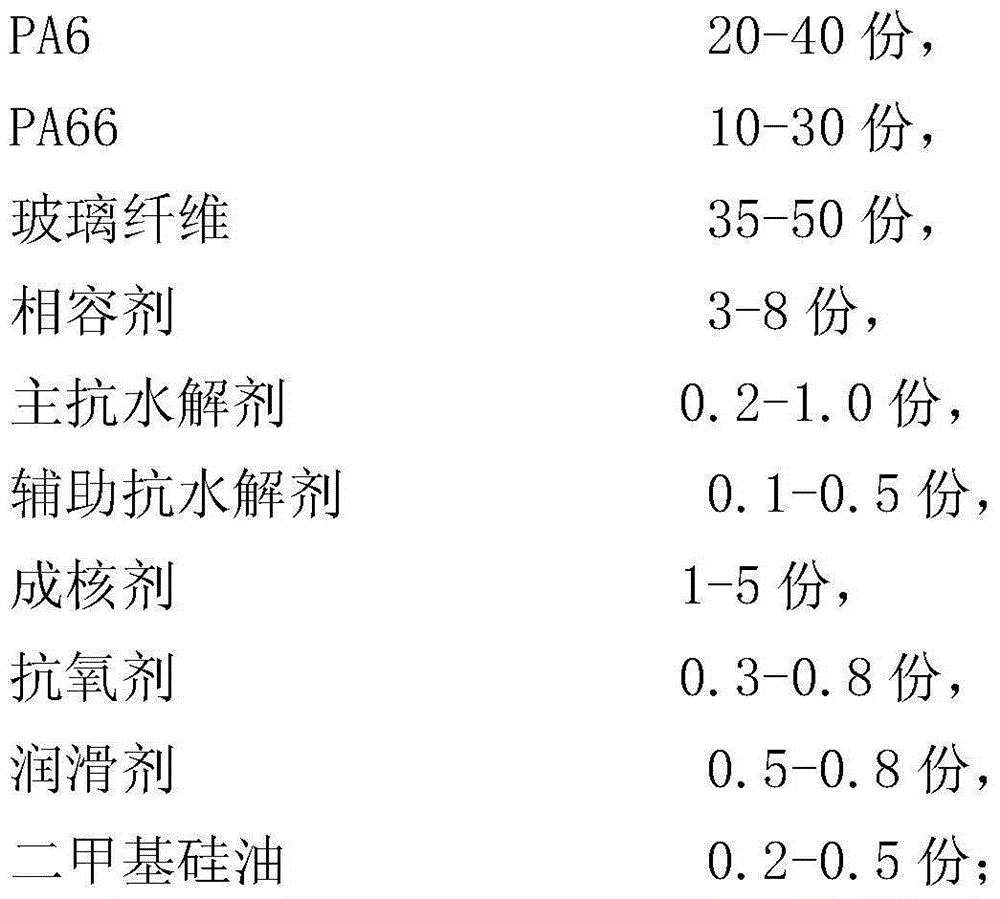

[0084] Glass fiber reinforced anti-hydrolysis nylon PA6 / PA66 composite material and its preparation method, the composition ratio according to the mass parts is as follows:

[0085] PA620-40 copies,

[0086] PA6610-30 copies,

[0087] 35-50 parts of glass fiber,

[0088] 3-8 parts of compatibilizer,

[0089] 0.2-1.0 parts of main anti-hydrolysis agent,

[0090] 0.1-0.5 parts of auxiliary anti-hydrolysis agent,

[0091] 1-5 parts of nucleating agent,

[0092] 0.3-0.8 parts of antioxidant,

[0093] 0.5-0.8 parts of lubricant,

[0094] 0.2-0.5 parts of dimethyl silicone oil.

[0095] The antioxidant described in the above composition is a compound of hindered phenolic antioxidant 1010 and phosphite antioxidant 168, and the ratio of antioxidant 1010 to 168 is 2:1; The anti-hydrolysis agent short glass fiber is 2-oxazoline or 3-oxazoline or 4-oxazoline or their mixture; the auxiliary anti-hydrolysis agent is epoxy compound which is phenyl glycidyl ether or bisphenol A One of bisglycidyl ether, t...

Embodiment 2

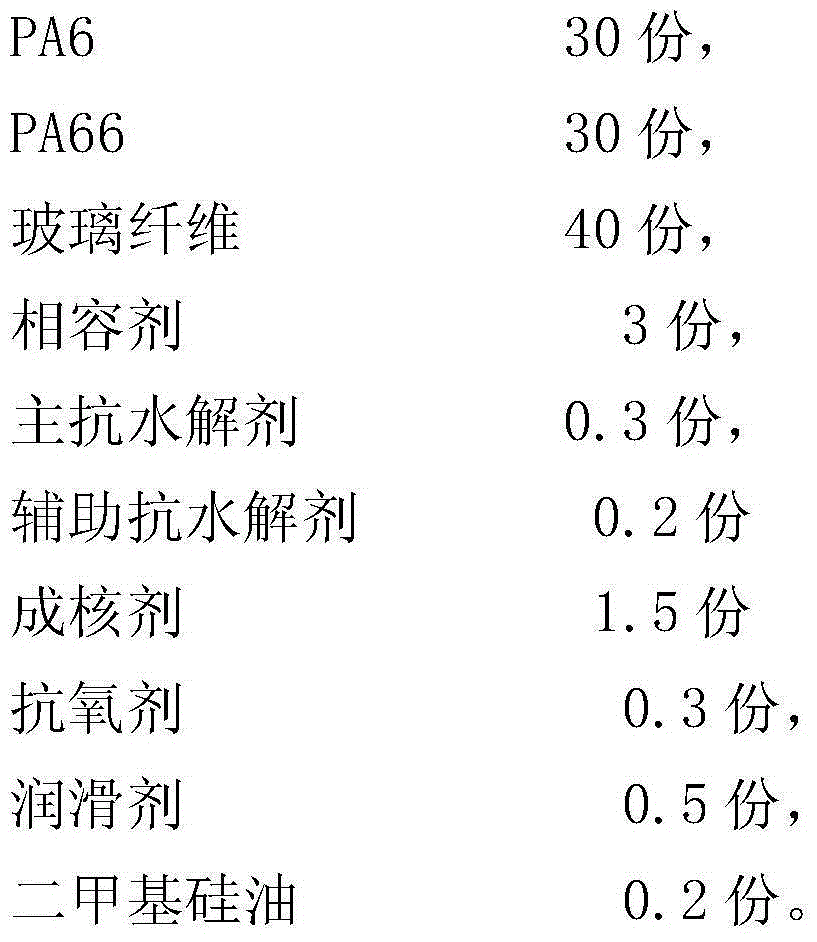

[0104] Glass fiber reinforced anti-hydrolysis nylon PA6 / PA66 composite material and its preparation method, the composition ratio according to the mass parts is as follows:

[0105] PA630 copies,

[0106] PA6630 copies,

[0107] 40 parts of glass fiber,

[0108] 3 parts of compatibilizer,

[0109] 0.3 parts of main anti-hydrolysis agent,

[0110] Auxiliary anti-hydrolysis agent 0.2 parts

[0111] 1.5 parts of nucleating agent

[0112] 0.3 parts of antioxidant,

[0113] 0.5 parts of lubricant,

[0114] 0.2 parts of dimethyl silicone oil.

[0115] The antioxidant described in the above composition is a compound of hindered phenolic antioxidant 1010 and phosphite antioxidant 168, and the ratio of antioxidant 1010 to 168 is 2:1; The anti-hydrolysis agent short glass fiber is 2-oxazoline or 3-oxazoline or 4-oxazoline or their mixture; the auxiliary anti-hydrolysis agent is epoxy compound which is phenyl glycidyl ether or bisphenol A One of bisglycidyl ether, tetrakis (phenyl glycidyl ether) etha...

Embodiment 3

[0118] Glass fiber reinforced anti-hydrolysis nylon PA6 / PA66 composite material and its preparation method, the composition ratio according to the mass parts is as follows:

[0119] PA620 copies,

[0120] PA6635 copies,

[0121] 45 parts of glass fiber,

[0122] 5 parts of compatibilizer,

[0123] 0.4 parts of main anti-hydrolysis agent,

[0124] 0.3 parts of auxiliary anti-hydrolysis agent,

[0125] 2 parts of nucleating agent,

[0126] 0.5 part of antioxidant,

[0127] 0.8 parts of lubricant,

[0128] 0.4 parts of dimethyl silicone oil,

[0129] The antioxidant described in the above composition is a compound of hindered phenolic antioxidant 1010 and phosphite antioxidant 168, and the ratio of antioxidant 1010 to 168 is 2:1; The anti-hydrolysis agent short glass fiber is 2-oxazoline or 3-oxazoline or 4-oxazoline or their mixture; the auxiliary anti-hydrolysis agent is epoxy compound which is phenyl glycidyl ether or bisphenol A One of bisglycidyl ether, tetrakis (phenyl glycidyl ether) et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com