Continuous reactive distillation equipment for synthesising methoxylamine hydrochloride and process thereof

A technology of methoxyamine hydrochloride and reactive distillation, which is applied in the field of continuous reactive distillation, can solve the problems of low equipment production capacity, large consumption of process raw materials, long production cycle, etc., and achieve stable product quality, good product quality, The effect of reducing production energy consumption and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

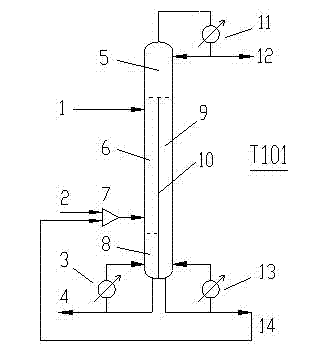

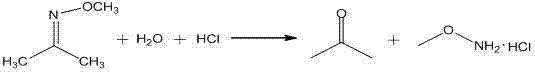

[0040] Attached figure 1 The schematic diagram of the equipment structure is shown. After the raw material oxime methyl ether is preheated, the temperature is 50°C, the flow rate is 300kg / h, and it enters the lower part of the reaction section of the reactive distillation dividing wall tower; the raw material hydrochloric acid with a mass concentration of 30% has a temperature of 25°C, the flow rate is 336kg / h, and it enters the reactive rectification dividing wall tower from the upper part of the reaction section; the molar ratio of hydrogen chloride and methyl oximide in hydrochloric acid is 0.8:1, and the two raw materials undergo acidic hydrolysis reaction of methyl oximide in the reaction section and Carry out vapor-liquid mass transfer separation and realize the process of continuous reactive distillation.

[0041] The material of the reactive distillation dividing wall tower is carbon steel lined with enamel. The reaction section of the reactive distillation dividing wa...

Embodiment 2

[0044] Attached figure 1 The schematic diagram of the equipment structure is shown. After the raw material oxime methyl ether is preheated, the temperature is 40°C, the flow rate is 240kg / h, and it enters the lower part of the reaction section of the reactive distillation dividing wall column; the raw material hydrochloric acid with a mass concentration of 30% has a temperature of 25°C, the flow rate is 638kg / h, it enters the reactive rectification dividing wall tower from the upper part of the reaction section; the molar ratio of hydrogen chloride and methyl oximide in hydrochloric acid is 1.9:1, and the two raw materials undergo acidic hydrolysis reaction of methyl oximide in the reaction section and Carry out vapor-liquid mass transfer separation and realize the process of continuous reactive distillation.

[0045] The material of the reactive distillation dividing wall tower is carbon steel lined with enamel. The reaction section of the reactive distillation dividing w...

Embodiment 3

[0048] Attached figure 1 The schematic diagram of the equipment structure is shown. After the raw material oxime methyl ether is preheated, the temperature is 50°C, the flow rate is 300kg / h, and it enters the lower part of the reaction section of the reactive distillation dividing wall column; the raw material hydrochloric acid with a mass concentration of 20% has a temperature of 25°C, the flow rate is 755kg / h, it enters the reactive rectification dividing wall tower from the upper part of the reaction section; the molar ratio of hydrogen chloride and methyl oximide in hydrochloric acid is 1.2:1, and the two raw materials undergo acidic hydrolysis reaction of methyl oximide in the reaction section and Carry out vapor-liquid mass transfer separation and realize the process of continuous reactive distillation.

[0049] The material of the reactive distillation dividing wall tower is carbon steel lined with enamel. The reaction section of the reactive distillation dividing wall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com