Integrated process for treating heavy metal wastewater

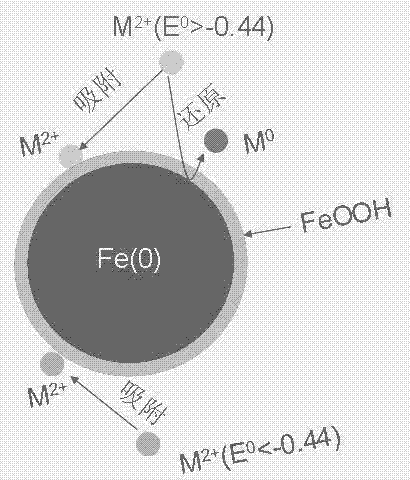

A heavy metal and wastewater technology, applied in water/sewage treatment, adsorbed water/sewage treatment, reduced water/sewage treatment, etc. It can solve the problem of reducing the concentration of nano-zero valent iron, large area of the reactor, and inability to guarantee the treatment effect, etc. problem, to achieve the effect of excellent treatment effect, low production cost, simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] At 25°C, add a certain amount of lead, copper, nickel, zinc, and zinc compounds to distilled water to prepare simulated wastewater for later use. The concentrations of heavy metal ions in the simulated wastewater are shown in Table 1.

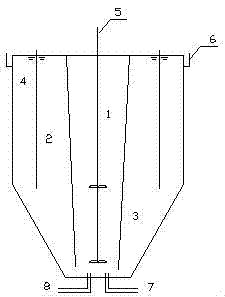

[0040] The reactor used in this example is a new type of integrated reactor. The main body of the reaction device is a similar cylindrical reactor 2, made of plexiglass, mainly including the main reaction zone 1, the reflux zone 2, the precipitation zone 3, and the water outlet zone. 4 and the agitator 5, the upper edge of the water outlet area is provided with a water guide 6, and the two ends of the bottom of the main reaction area 1 are respectively provided with a heavy metal waste water inlet 7 and a nanometer zero-valent iron inlet 8.

[0041] The simulated wastewater is fed from the water inlet of the reactor, and the nano-zero-valent iron ethanol solution to be used enters the device from the bottom inlet, so that the concent...

Embodiment 2

[0046] Take the electroplating wastewater stock solution at the exit of the electroplating workshop of an electroplating factory, first pretreat the electroplating wastewater stock solution: add a certain amount of PAM flocculant, first stir quickly for 1-2 minutes to mix the added flocculant in the solution evenly, and then reduce the stirring speed , slowly stir the electroplating wastewater for 30-60 min, so that the suspended impurities in the electroplating wastewater stock solution coagulate into flocs, stop stirring after the flocculation is completed, and let the electroplating wastewater stand for 1-3 h to settle, and filter it with filter paper after the precipitation is completed. Obtain clarified electroplating wastewater. The electroplating wastewater after pretreatment contains Zn 2+ 400~500mg / L, Cu 2+ , Pb 2+ 、Ni 2+ 600~800mg / L, pH between 5~7.

[0047] The reactor used in this example is a new type of integrated reactor. The main body of the reaction devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com