Condensation enhancement and heating type seawater desalter

A heating type, water receiving tank technology, applied in the direction of heating water/sewage treatment, seawater treatment, general water supply saving, etc., can solve the problems of small contact area, large heat loss, slow heat dissipation, etc., to improve the contact area, Improved heating capacity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

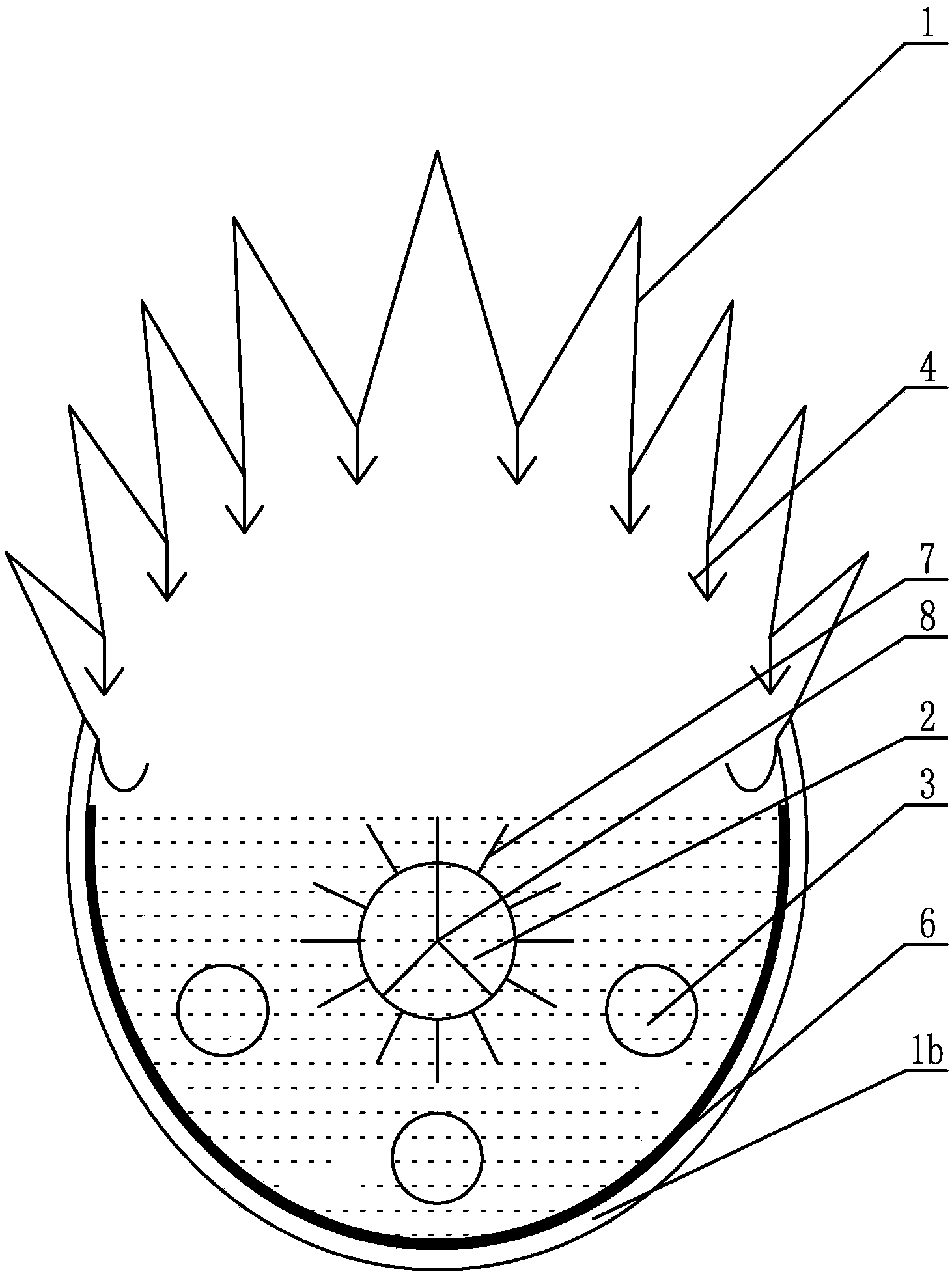

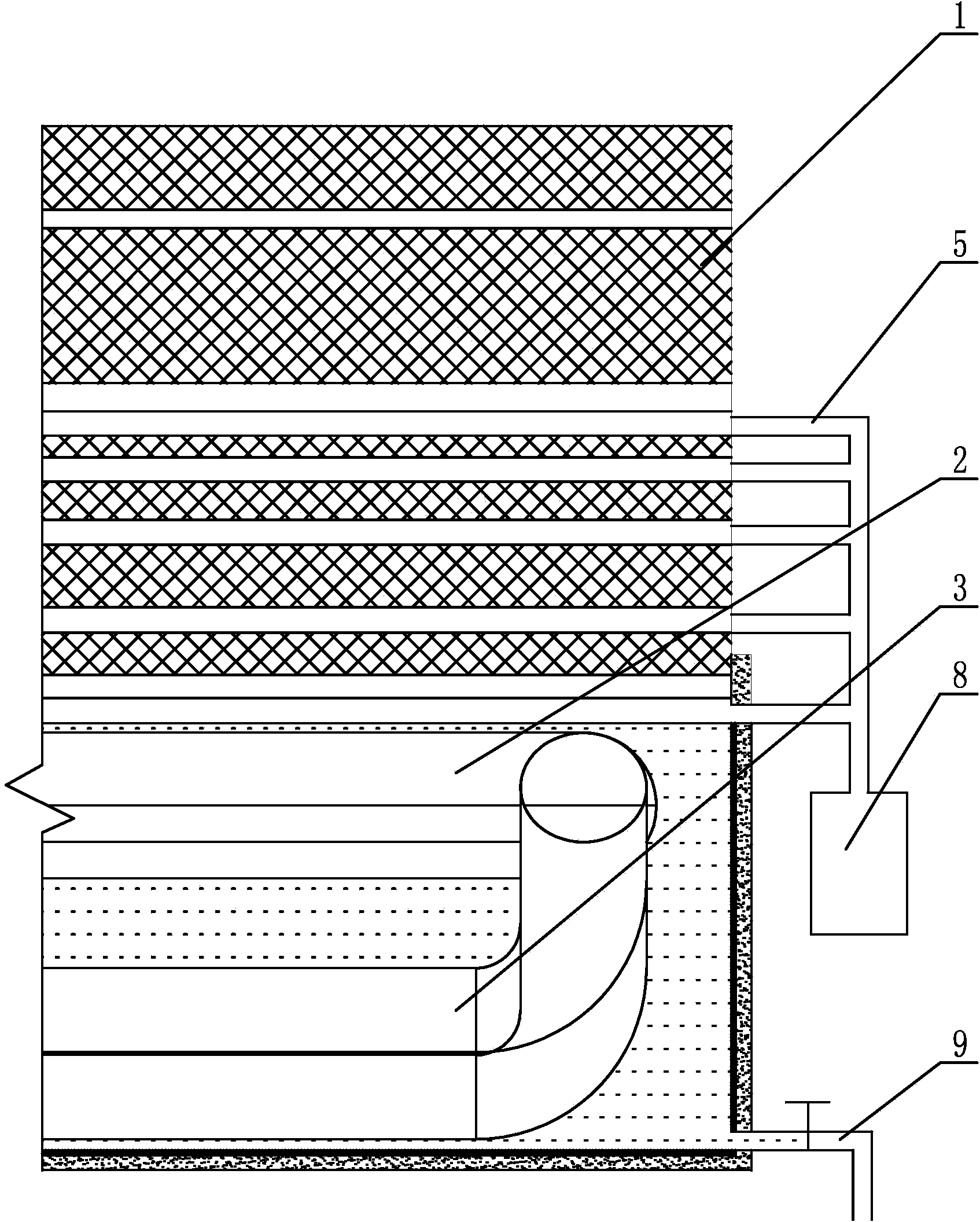

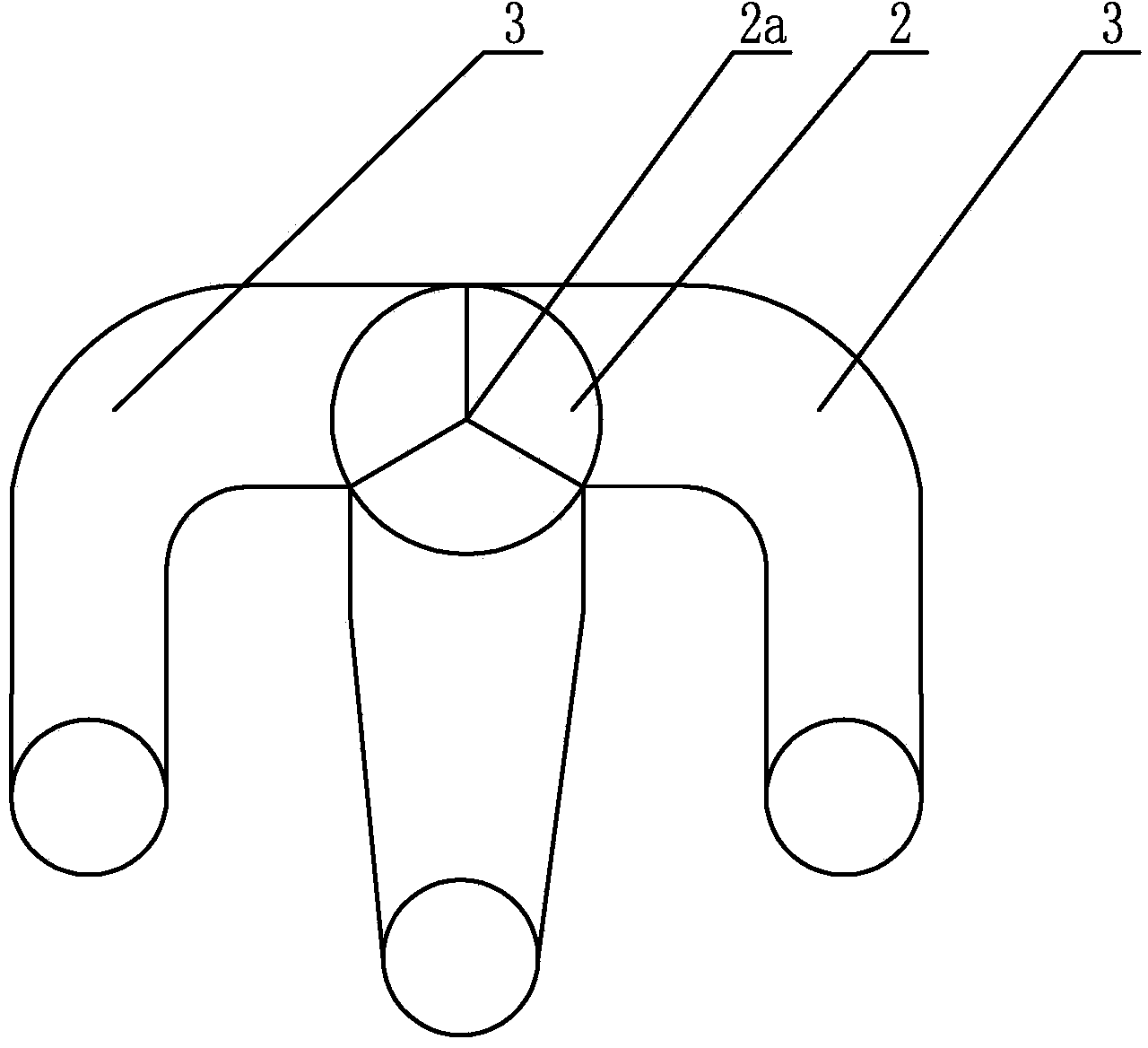

[0015] Such as figure 1 , figure 2 with image 3 As shown, the present invention is composed of shell 1, oil inlet pipe 2, oil outlet pipe 3, water receiving tank 4, fresh water output pipe 5, thermal insulation layer 6 and cooling ribs, and the upper half of the shell 1 is arc-shaped and sawtooth A water receiving tank 4 is arranged below each groove of the sawtooth, and the water receiving tank 4 is fixedly connected in the housing 1 along the axial direction, and one end of each of the water receiving tanks 4 is connected with the fresh water output pipe 5 . The bottom of the shell 1 is a vacuum chamber 1b, and an insulation layer 6 is installed on the inner wall of the bottom of the shell 1, and the bottom of the shell 1 is provided with a concentrated brine output pipe 9, and the concentrated brine output pipe 9 communicates the shell 1 with the outside world. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com