Samarium-containing praseodymium and neodymium-free hydrogen storage alloy for nickel-hydrogen power battery

A hydrogen storage alloy and power battery technology, which is applied in the field of samarium-containing, praseodymium-free and neodymium-containing hydrogen storage alloys for nickel-hydrogen power batteries, can solve the problems of unmentioned alloys, high production costs, decreased competitiveness, etc., and achieves high discharge voltage and capacity, good high-current discharge, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

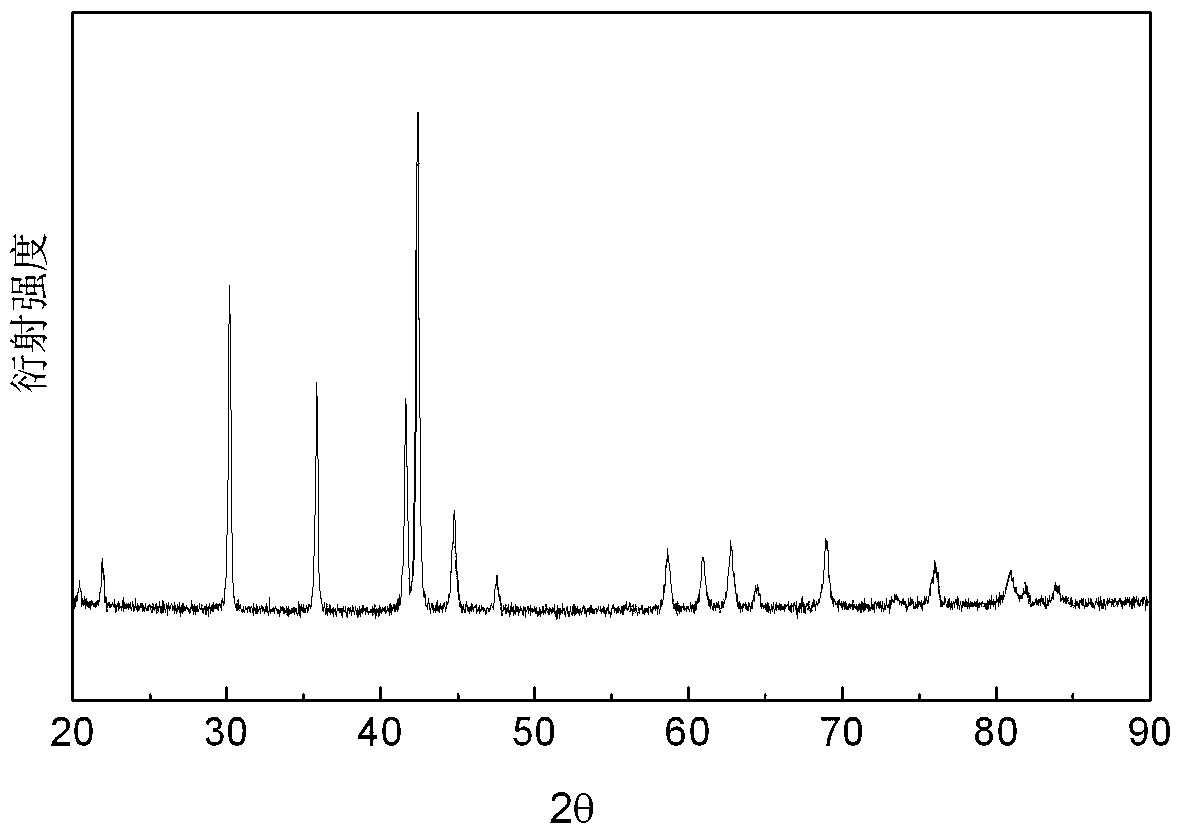

[0009] surface The composition of the hydrogen storage alloy

[0010]

[0011] According to the alloy composition ratio, the rare earth element is in the form of lanthanum-rich rare earth alloy, the element Sm is added in the form of simple substance, and the purity of other metals is above 99.5%. The prepared raw materials are vacuumed to 0.05Pa in a vacuum quenching furnace, and then passed Argon protection, pressure about 0.05MPa, melting and throwing into 0.05~0.1mm hydrogen storage alloy sheet, heat treatment at 800~1050°C for 4~8 hours, after cooling, mechanical ball milling and sieving , to obtain hydrogen storage alloy powder with particle size less than 0.08mm.

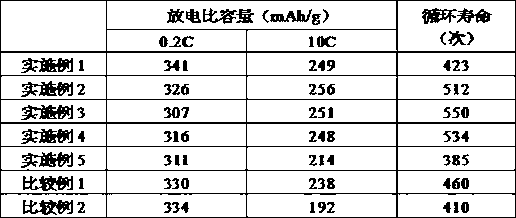

[0012] According to the above hydrogen storage alloy powder preparation process, the hydrogen storage alloy powder Examples 1 to 6 with the composition shown in Table 1 were obtained, and the comparative example used commercially available hydrogen storage alloy powder for power nickel-hydrogen batter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com