Synchronous saccharification and ethanol fermentation method with lignocelluloses treated by steam explosion method as raw material

A lignocellulose and ethanol fermentation technology, applied in the field of simultaneous saccharification and ethanol fermentation, can solve the problems of increasing equipment investment and cost, low ethanol content, etc., and achieve the effects of simplifying the production process, reducing water consumption, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. Unless otherwise specified, the technical means used in the examples are conventional means well known to those skilled in the art, and the raw materials used are all commercially available products.

[0026] The Saccharomyces cerevisiae Y5 with the preservation number CGMCC No. 2660 involved in the present invention was provided by the School of Life Sciences, Capital Normal University.

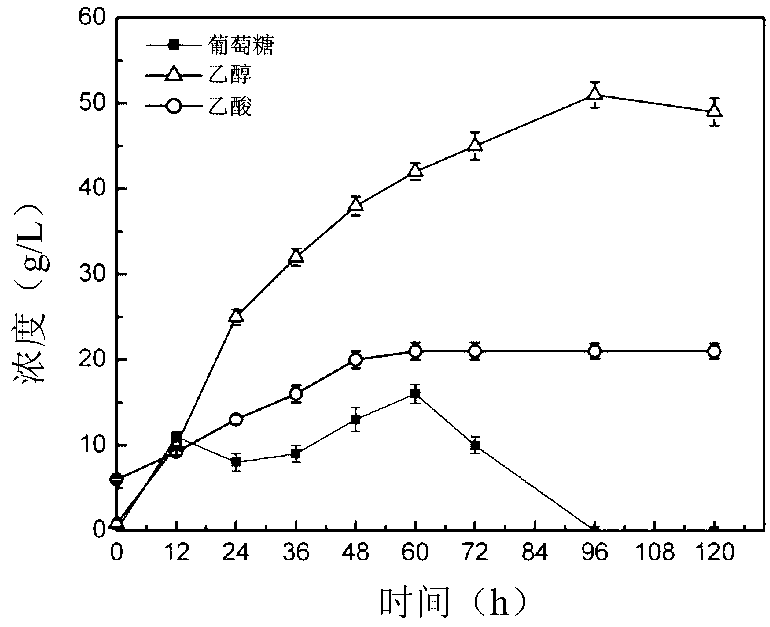

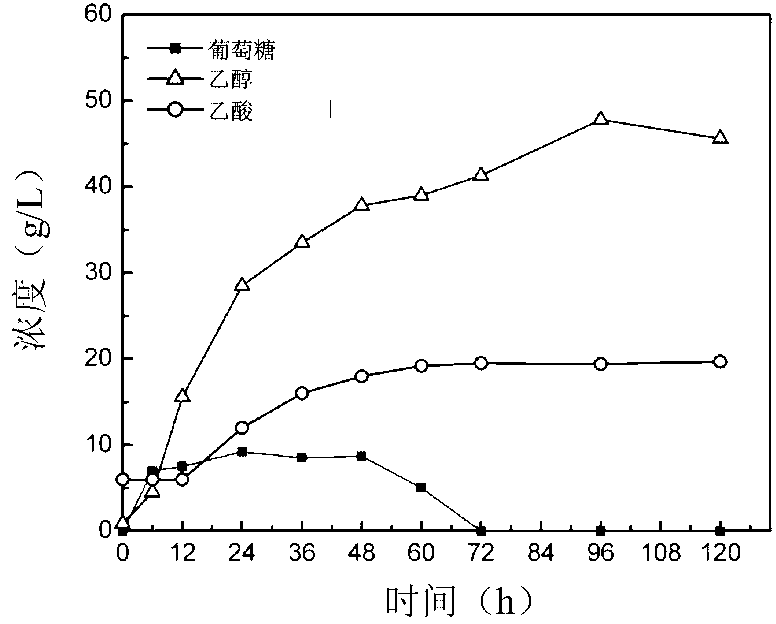

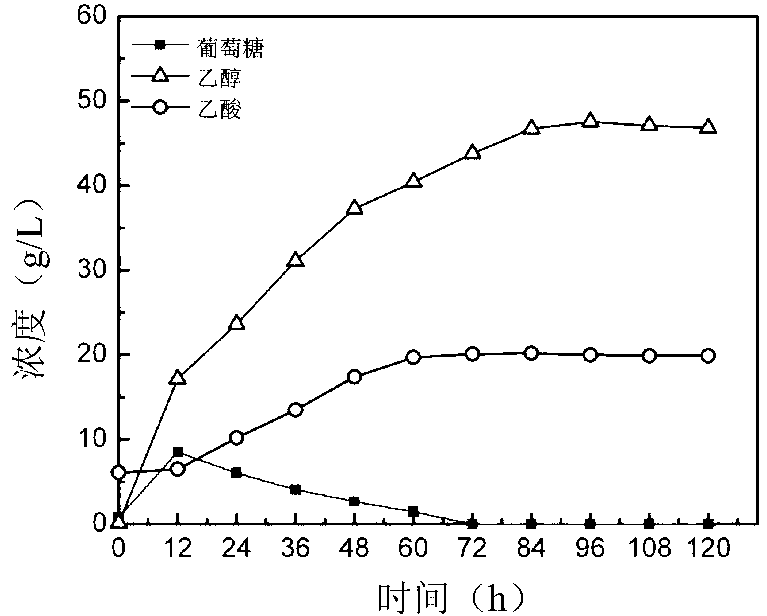

[0027] Embodiment Synchronous saccharification and ethanol fermentation method using steam explosion pretreated lignocellulose as raw material

[0028] 1.1 Materials and instruments

[0029] Corn straw used for steam explosion pretreatment was provided by Henan Tianguan Enterprise Group Co., Ltd. KYC type constant temperature culture shaker, German Sartorius BIOSTAT B plus5L automatic fermenter.

[0030] 1.2 Steam explosion pretreatment of corn stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com