Method for preparing 1,3-dihydric alcohol directly from olefin

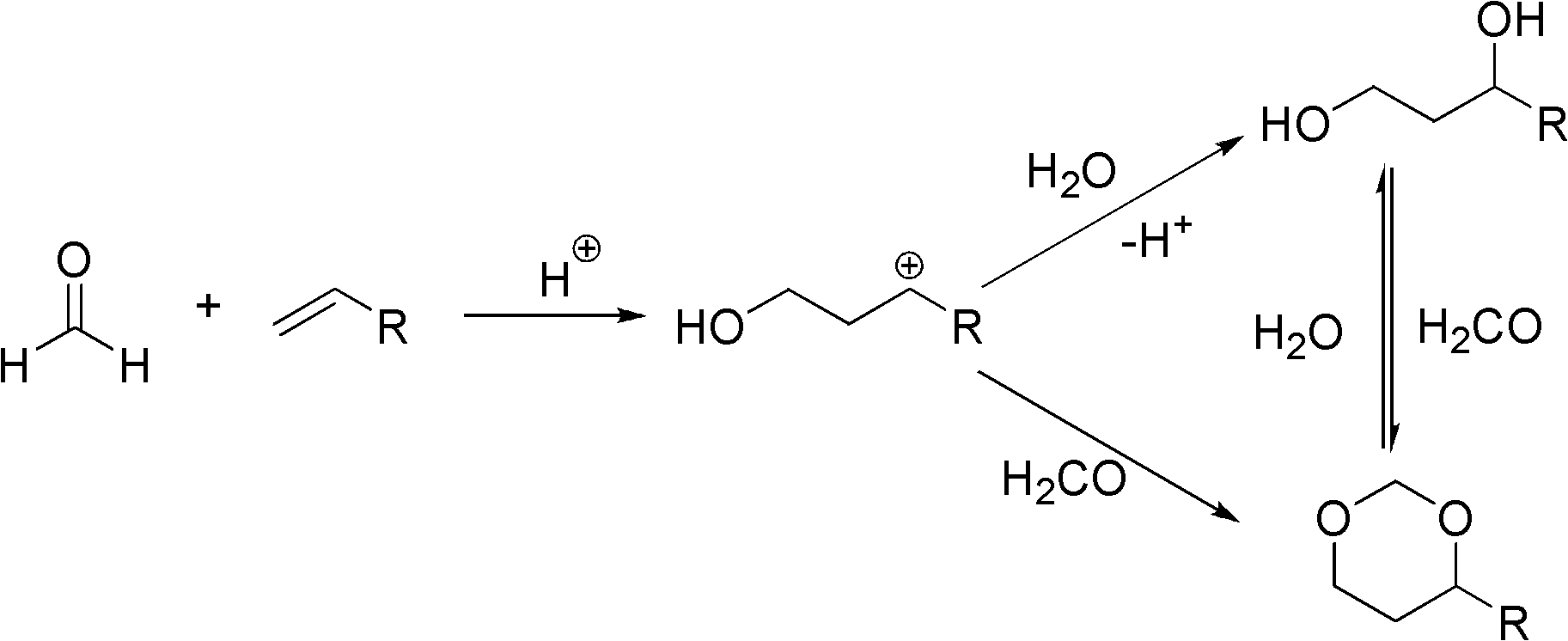

A technology of diols and olefins, which is applied in the field of direct preparation of 1,3-diols from olefins, which can solve the problems of easy deactivation of catalysts, difficulty in separation, and low yield, and achieve the effect of broadening product categories and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

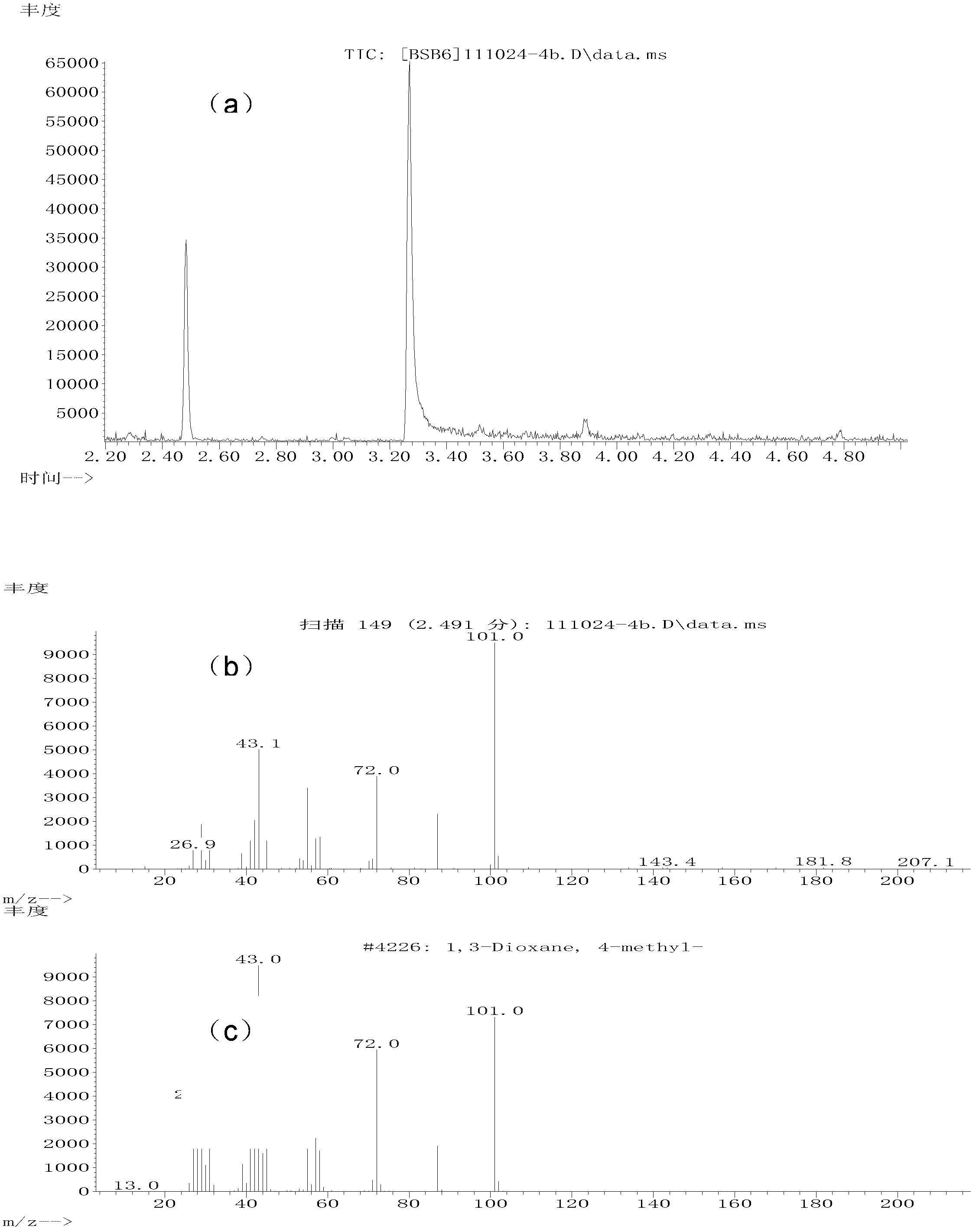

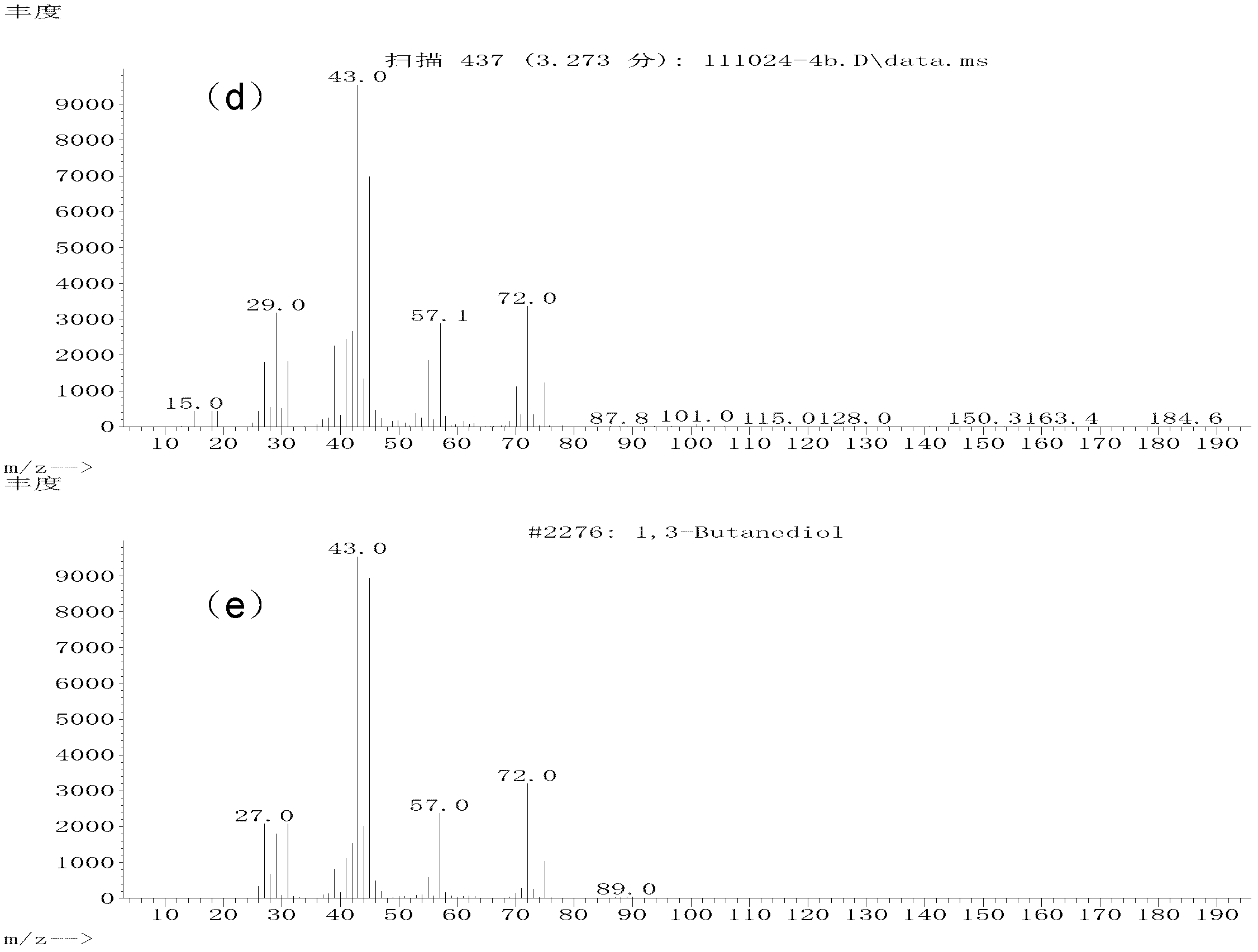

[0024] In a 250ml Teflon-lined reactor, add 60mmol 38% formaldehyde solution and 90mmol isobutylene respectively, weigh 3g SnO 2 Catalyze the reaction, add 10ml of water, and stir the reaction at 200°C for 10 hours. After the reaction, the product is detected by chromatography, and the mass spectrum of the product and the standard mass spectrum Figure 1 Sincerely. The yield of 3-methyl-1,3-butanediol is shown in Table 1.

Embodiment 2

[0026] In a 250ml Teflon-lined reactor, add 50mmol 38% formaldehyde solution and 90mmol ethylene respectively, and weigh 4g MoO 3 Catalyze the reaction, add 10ml of water, and stir the reaction at 170°C for 24 hours. After the reaction, the product is detected by chromatography, and the mass spectrum of the product and the standard mass spectrum Figure 1 Sincerely. 1,3-propanediol yield is shown in Table 1.

Embodiment 3

[0028] In a 250ml Teflon-lined reactor, add 0.12mol 38% formaldehyde solution and 60mmol ethylene respectively, weigh 5g WO 3 Catalyze the reaction, add 20ml of water, and stir the reaction at 150°C for 36 hours. After the reaction, the product is detected by chromatography, and the mass spectrum of the product is consistent with the standard mass spectrum Figure 1 Sincerely. 1,3-propanediol yield is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com