A kind of preparation method of high-adhesive non-adhesive flexible copper clad laminate

A flexible copper-clad laminate and glue-type technology, which is applied in the field of preparation of high-adhesive non-adhesive flexible copper-clad laminates, can solve the problems of inability to obtain ultra-thin flexible copper-clad laminates, difficulty in large-scale continuous production, and high production costs , to achieve good solubility and film-forming properties, low production cost, and low post-treatment temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

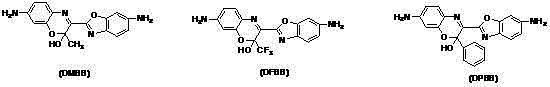

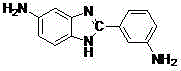

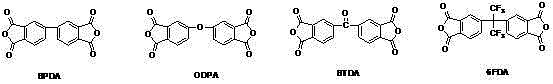

[0029] with N 2 In a 500mL four-neck flask with vent tube, thermometer and mechanical stirrer, under N 2 In the atmosphere, first add BIA5.6066g (0.025mol) and DMBB7.4050g (0.025mol), then add NMP250g, after the diamine is completely dissolved, add BPDA14.7112g (0.05mol). at 0 o C for 6 hours to generate the corresponding polyamic acid. Then add an appropriate amount of xylene to keep the reflux temperature at 150 o C. After continuing to heat for 24 hours, the xylene was completely distilled off, and the heating was stopped. After cooling down naturally, the reaction solution was poured into high-speed stirring methanol to obtain a precipitate. The obtained precipitate was thoroughly washed successively with methanol and anhydrous ether, filtered, dried naturally, and then dried in vacuum at 120°C for 24 hours to obtain polyimide powder. Using NMP as the mobile phase, the number average molecular weight (Mn) was 121325 and the weight average molecular weight (Mw) was 4003...

Embodiment 2

[0032] with N 2 In a 500mL four-neck flask with vent tube, thermometer and mechanical stirrer, under N 2 In the atmosphere, first add BIA6.7279g (0.030mol) and DFBB7.0040g (0.0020mol), then add NMP250g, after the diamine is completely dissolved, add ODPA15.5320g (0.05mol). at 15 o C for 8 hours to generate the corresponding polyamic acid. Add an appropriate amount of chlorobenzene to keep the reflux temperature at 180 o C. After continuing to heat for 18 hours, the chlorobenzene was completely distilled off, and the heating was stopped. After cooling down naturally, the reaction liquid was poured into high-speed stirring methanol to obtain a precipitate. The obtained precipitate was thoroughly washed successively with methanol and anhydrous ether, filtered, dried naturally, and then dried in vacuum at 120°C for 24 hours to obtain polyimide powder. Using NMP as the mobile phase, the number average molecular weight (Mn) was 78325 and the weight average molecular weight (Mw) ...

Embodiment 3

[0035] with N 2 In a 500mL four-neck flask with vent tube, thermometer and mechanical stirrer, under N 2 In the atmosphere, first add BIA7.8493g (0.0350mol) and DPBB5.3741g (0.0150mol), then add NMP250g, after the diamine is completely dissolved, add BTDA16.1325g (0.0500mol). at 40 o C for 10 hours to generate the corresponding polyamic acid. Then add an appropriate amount of xylene to keep the reflux temperature at 160 o C. After continuing to heat for 48 hours, completely distill out the xylene, stop heating, wait for it to cool naturally, pour the reaction solution into high-speed stirring methanol, and obtain a precipitate. The obtained precipitate was thoroughly washed successively with methanol and anhydrous ether, filtered, dried naturally, and then dried in vacuum at 120°C for 24 hours to obtain polyimide powder. Using NMP as the mobile phase, the number average molecular weight (Mn) was 58354 and the weight average molecular weight (Mw) was 97546 as measured by ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com