Lithium ion battery film in situ preparation method, lithium ion battery film, and lithium ion battery

A lithium-ion battery, in-situ preparation technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of low longitudinal tensile strength of nanofiber films, difficult lamination and winding, and low puncture strength, etc. Achieve good thermal stability, avoid weak adhesion, and easily adjust the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Taking the preparation of a lithium-ion battery film with a PVDF separator as an example, the in-situ preparation method of the present invention is further described.

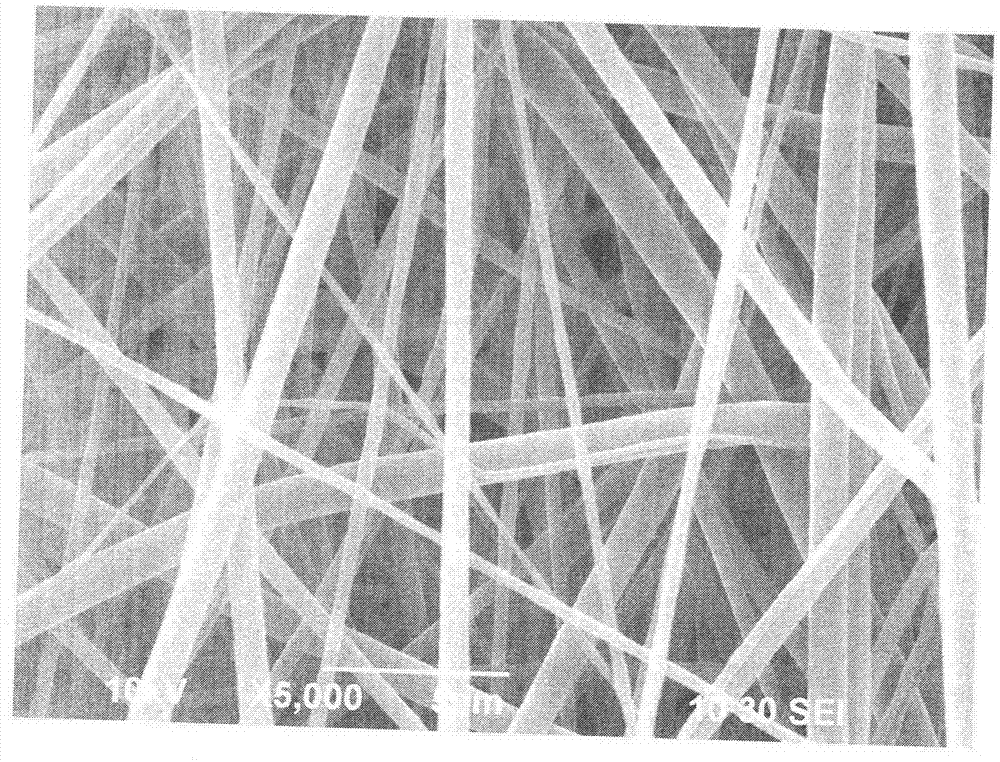

[0029] Select the intrinsic viscosity as 5.0-15 10 2 mL / g, PVDF resin with a rotational viscosity of 2.5-7.5Pa·s and a moisture content of not more than 0.2% is used to prepare a polyvinylidene fluoride solution with a weight concentration of 7.2%. Coating LiFePO on the surface of metal aluminum foil 4 The electrode sheet is conveyed circularly between the discharge roller and the take-up roller, and the electrode sheet conveying speed is 100cm / min. The electric field strength applied between the nozzle and the take-up roller is 1500V / cm, the distance is 15cm, and the moving speed of the nozzle is 20-50cm / min; through the tension adjustment mechanism, the vertical section of the coating area is controlled to maintain the roller ratio of the vertical section of the coating area to maintain the tension o...

Embodiment 2

[0031] Compared with Example 1, the only difference is that LiFePO is coated on the surface of metal aluminum foil 4 Before the glow discharge treatment was carried out on the aluminum foil, the conditions of the glow discharge treatment were: the background vacuum degree was 5.0 10 -3 Pa, under the conditions of DC voltage 150V and current 0.5A, use argon gas to generate glow discharge treatment for 5min. The prepared film has uniform thickness, uniform pore distribution, 45% porosity, good thermal stability, and two-way shrinkage < 0.6% when kept at 90° C. for 4 hours.

Embodiment 3

[0033] Compared with Embodiment 2, the only difference is that the heat treatment device is an electron beam curing device. The prepared film has uniform thickness, uniform pore distribution, porosity of 52%, good thermal stability, and two-way shrinkage <0.5% when kept at 90° C. for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com