Floating type lithium niobate optical waveguide

A technology of lithium niobate and optical waveguide, which is applied in the direction of optical waveguide, light guide, optics, etc., can solve the problems of reducing transmission loss and difficulty in processing lithium niobate crystals with different ratios, so as to achieve reduced transmission loss, low transmission loss, Improve the effect of transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

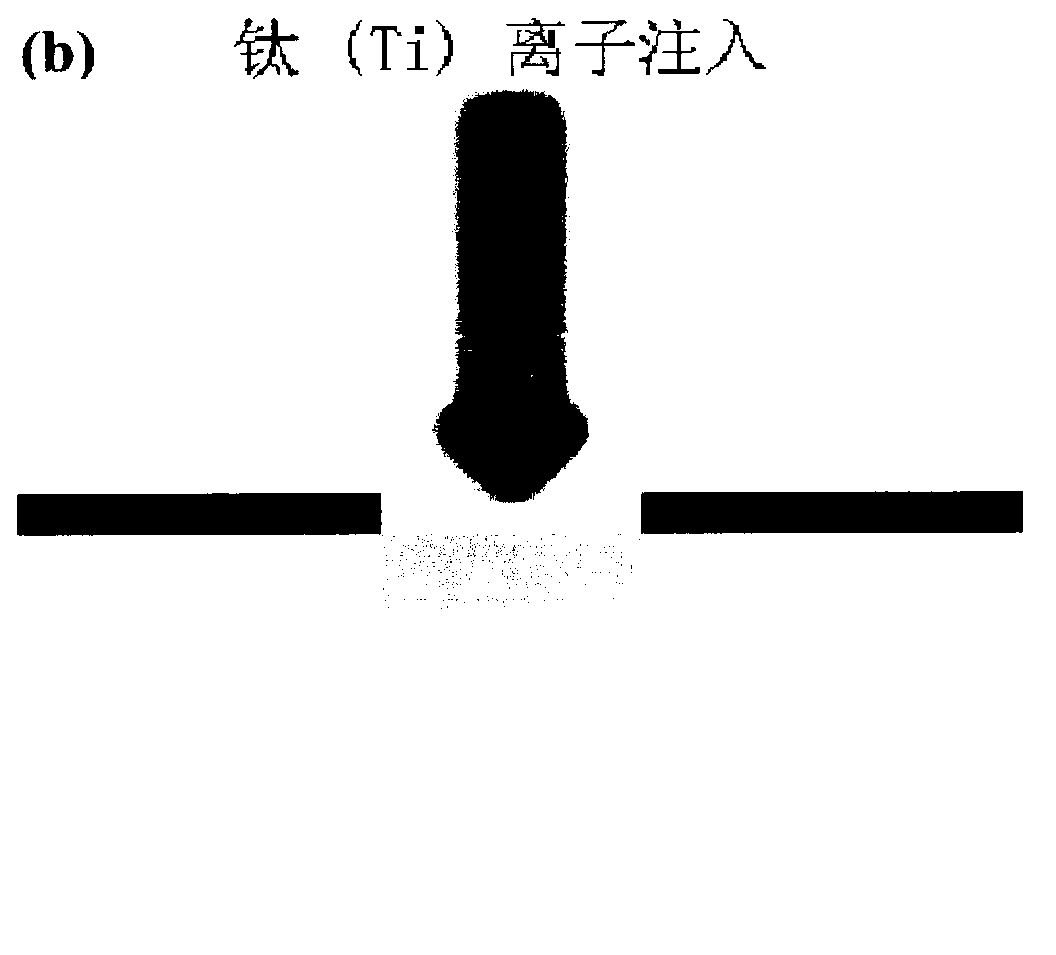

[0027] Example: see attached Figure 6 , Suspended lithium niobate optical waveguide, characterized in that: select lithium niobate sample as the substrate and operate according to the following steps, first, use a helium ion (He+) beam with an energy of 1 megaelectron volt (MeV) to bombard lithium niobate In the sample, lattice damage is formed in a certain area under the sample surface, and the portion where the lattice damage is formed has a refractive index smaller than the portion without damage, so a difference in refractive index can be formed, and then a waveguide is formed to confine the beam to propagate in the waveguide area. However, similar to the traditional proton exchange and titanium diffusion methods, the refractive index contrast difference caused by the lattice damage caused by helium ion bombardment is small, especially in the vertical direction, where light can easily leak to the substrate during transmission. direction and dissipate to form losses. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com