Microencapsulation red phosphorus fire retardation antistatic polyethylene pipe composition

A technology for microencapsulating red phosphorus and polyethylene pipes, applied in the field of plastic processing, can solve problems such as poor flame retardant effect, and achieve the effects of good physical and mechanical properties, low raw material cost and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

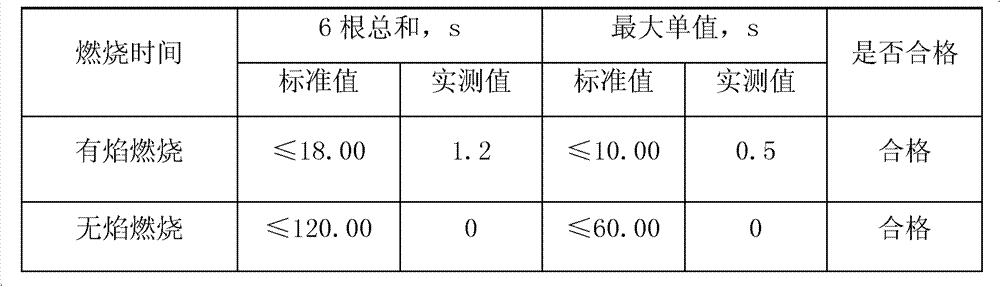

[0032] Table 1 is the embodiment of the present invention and comparative example

[0033] raw material

Example 1

Example 2

Example 3

Comparative example 4

Comparative example 5

High-density polyethylene

53.2

54.2

43.2

100

100

Linear Low Density Polyethylene

10

20% conductive carbon black masterbatch

30

30

30

30

30

Microencapsulated red phosphorus

6

7

9

12

14

MCA

8

10

6

Dispersant

1.5

1.5

1.5

1.5

1.5

1.0

1.0

1.0

1.0

1.0

Antioxidant 1010

0.15

0.15

0.15

0.15

0.15

Antioxidant 168

0.15

0.15

0.15

0.15

0.15

[0034] The sample preparation method of embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com