Inorganic foamed concrete insulation board and preparation method thereof

An inorganic foaming and thermal insulation board technology, which is used in ceramic products, other household appliances, household appliances, etc., can solve the problems of high bulk density, long condensation time, and poor thermal conductivity of thermal insulation boards, and achieves low thermal conductivity and good thermal insulation effect. , the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

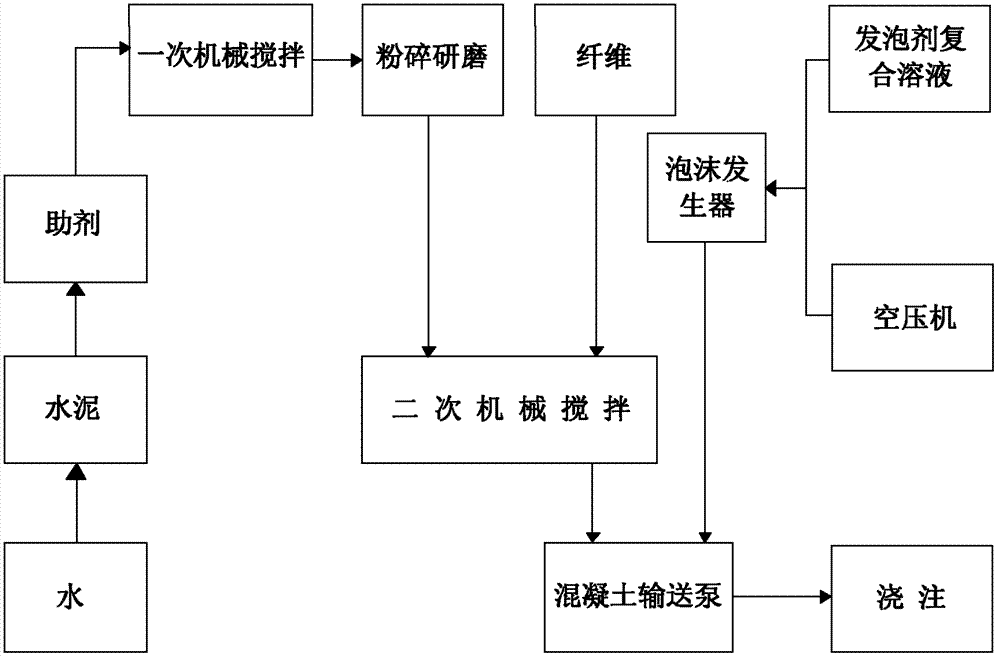

Embodiment 1

[0025] No. 32.5 cement, water, latex powder, early strength agent, calcium formate, water reducing agent, waterproofing agent and calcium stearate according to the ratio of 1: 0.6: 0.1: 0.2%: 0.2%: 0.2%: 0.2%: 0.2% Mixing by weight ratio, and stirring once until uniform; then, pulverizing the agitated material; then, mixing the pulverized material with fibers and then stirring again until uniform, the weight ratio of the fiber to the cement is 0.1%:1, Afterwards, the secondary mixture is foamed by a concrete foaming machine, and then poured.

Embodiment 2

[0027] No. 32.5 cement, water, latex powder, early strength agent, calcium formate, water reducing agent, waterproofing agent and calcium stearate according to the ratio of 1: 0.7: 0.5: 0.5%: 0.5%: 0.5%: 0.5%: 0.5% Mixing by weight ratio, and stirring once until uniform; then, pulverizing the agitated material; then mixing the pulverized material with fibers and stirring again until uniform, the weight ratio of the fiber to the cement is 0.3%: 1, and then Foam the secondary mixture through a concrete foaming machine before pouring.

Embodiment 3

[0029] No. 32.5 cement, water, industrial emulsion, early strength agent, calcium formate, water reducing agent, waterproofing agent and calcium stearate according to the ratio of 1: 0.65: 0.3: 0.4%: 0.4%: 0.4%: 0.4%: 0.4% Mixing by weight ratio, and stirring once until uniform; then, pulverizing the agitated material; then mixing the pulverized material with fibers and stirring again until uniform, the weight ratio of the fiber to the cement is 0.2%: 1, and then Foam the secondary mixture through a concrete foaming machine before pouring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com