Porous lithium iron phosphate/carbon composite microspheres and preparation method thereof

A lithium iron phosphate and carbon composite technology, used in phosphorus compounds, chemical instruments and methods, structural parts, etc., can solve the problems of low output, inability to industrialize production, uniform molecular level, and inability to achieve solid-phase methods, and achieve high tap density. , The effect of improving energy density and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

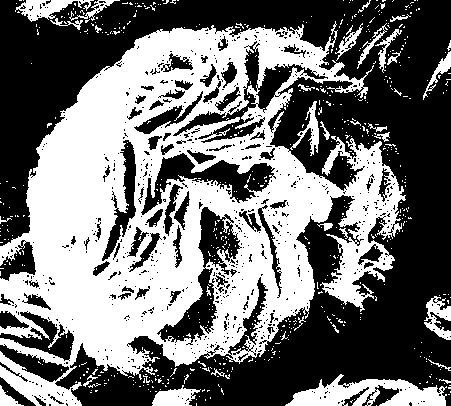

[0033] The preparation method of porous lithium iron phosphate / carbon composite microspheres described in this embodiment specifically includes the following steps:

[0034] (1) At room temperature, 0.1 mol of Fe(NO 3 ) 3 9H 2 O and 0.1 mol of H 3 PO 4 (H with a purity of 85% 3 PO 4 solution) mixed with 100 mL of ethanol, ultrasonically or stirred to dissolve, then added 0.1 mol LiOH and stirred until dissolved.

[0035] (2) Add 0.1L 1mol / L oxalic acid ethanol solution dropwise to the above mixed solution, accompanied by vigorous stirring during the addition. After reacting for 1 hour, a uniform yellow jelly was obtained, which was fully dried at 80° C. to obtain a yellow-white iron phosphate oxalate powder.

[0036] (3) Disperse 0.1 mol of iron phosphate oxalate powder and 8 g of glucose into 30 mL of water, mix and grind for 1 hour, then fully dry at 80°C, and then calcinate the mixture at 650°C under the protection of argon / hydrogen gas containing 5% hydrogen 24 h t...

Embodiment 2

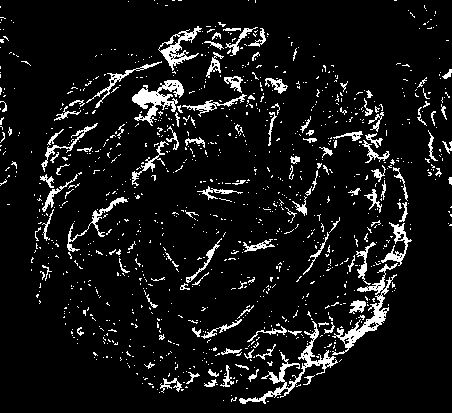

[0038] The preparation method of porous lithium iron phosphate / carbon composite microspheres described in this embodiment specifically includes the following steps:

[0039] (1) Add 0.1 mol Fe(NO 3 ) 3 9H 2 O and containing 0.1 mol LiH 2 PO 4 Aqueous solution (the amount of water used is only LiH 2 PO 4 Just dissolve it) mix and add to 200 mL ethanol and stir to dissolve.

[0040] (2) Add 100 mL of 1 mol / L oxalic acid ethanol solution dropwise to the above mixed solution, accompanied by vigorous stirring during the addition. After reacting for 3 hours, a uniform yellow jelly was obtained, which was fully dried at 60 °C to obtain a yellow-white powder.

[0041] (3) Add 50% of the precursor mass of sucrose, disperse it into 5 ml of water and grind it for 1 h, then fully dry it at 80 °C, and then calcinate the mixture at 700 °C for 10 h under the protection of argon / hydrogen gas containing 5% hydrogen to obtain the final product.

Embodiment 3

[0043] The preparation method of porous lithium iron phosphate / carbon composite microspheres described in this embodiment specifically includes the following steps:

[0044] (1) Mix 10 mmol iron acetate and 10 mmol H 3 PO 4 Mix and add 20 mL of ethanol, sonicate or stir to dissolve, then add 0.01 mol lithium acetate and stir until dissolved.

[0045] (2) Add 10 mL of 1.5 mol / L oxalic acid ethanol solution dropwise to the above mixed solution, accompanied by vigorous stirring during the addition. After 3 hours, a uniform yellow jelly was obtained, which was aged and dried at 60 °C to obtain a yellow-white powder.

[0046] (3) After adding citric acid with 50% of the mass of the precursor and mixing and milling for 1 h, the mixture was calcined at 750 °C for 10 h under the protection of argon / hydrogen gas containing 5% hydrogen to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com