Ketobutyric acid and preparation method for ketobutyric acid salt

A technology of methyl butyronic acid and oxobutyrate, which is applied in the preparation of carboxylic acid esters, organic compounds, carboxylic acid esters/lactones, etc., can solve unfavorable industrial production and wide application, and low selectivity , high preparation cost, etc., to achieve the effect of being suitable for large-scale industrial application, high yield and purity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of 2-butanuonic acid.

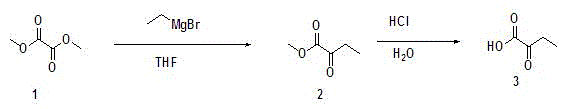

[0026] Dissolve 118 g of dimethyl oxalate in 2000 mL of anhydrous tetrahydrofuran, cool to -78°C, add 500 mL of 1 mol / L ethylmagnesium bromide solution, stir, react for 2 hours, and distill off the solvent under reduced pressure, leaving The mixture was then rectified under reduced pressure, and the intermediate product 2-oxobutyric acid methyl ester was collected to obtain 50 g, and the yield of 2-oxobutyric acid methyl ester was 76%. Dissolve 50 g of methyl 2-oxobutyrate collected in 2.5 L of 1 mol / L hydrochloric acid, heat to reflux, and stir for 2 h. After the reaction is monitored by TLC, extract three times with 3 L of ethyl acetate, collect The organic phase was dried by adding anhydrous magnesium sulfate, filtered, and the filtrate was distilled off under reduced pressure to obtain 43 g of crude product 2-butanuonic acid. The preparation process is as figure 1 As shown, the yield of 2-butyronic acid prepared from...

Embodiment 2

[0030] Example 2 Preparation of sodium 2-butanone.

[0031] Weigh 20 g of the crude product 2-butanuonic acid prepared in Example 1, dissolve it in 50 mL of methanol, cool to 0 °C, add 70 mL of 10% sodium hydroxide methanol solution, and react at this temperature for 10 min. Then the solvent was distilled off under reduced pressure at 25°C, the remaining solid was washed with 500 mL of ethyl acetate, and filtered to obtain a white solid. The solid was dried in a vacuum drying oven at room temperature for 2 h, and the final product was 17 g. The yield of sodium 2-butyruvate prepared from 2-butanuonic acid was 70%.

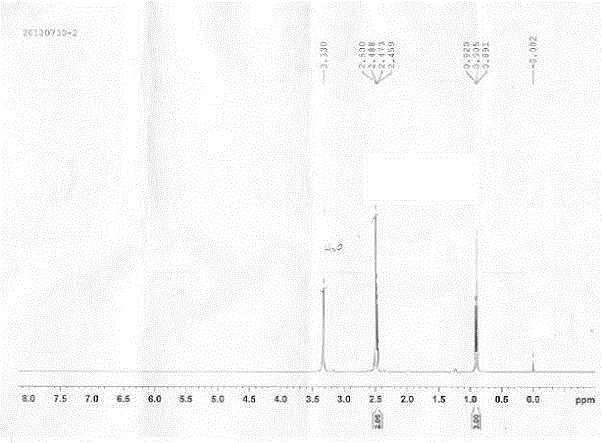

[0032] Therefore, the total productive rate of the preparation method of sodium 2-butyruvate provided by the invention is 52.1%, and the preparation process is as follows figure 2 shown. The prepared sodium 2-butanone is detected, and the result is as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com