Preparation method of nitrogen-doping ordered mesoporous carbon materials

A mesoporous carbon and nitrogen doping technology, which is applied in the preparation/purification of carbon, etc., can solve the problems of affecting performance, low doping amount of nitrogen-doped ordered carbon materials, etc., and achieve high mesopority and doping amount High, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

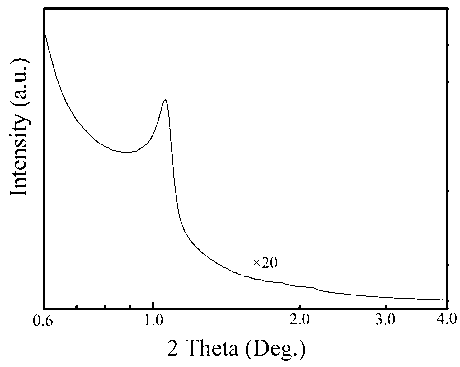

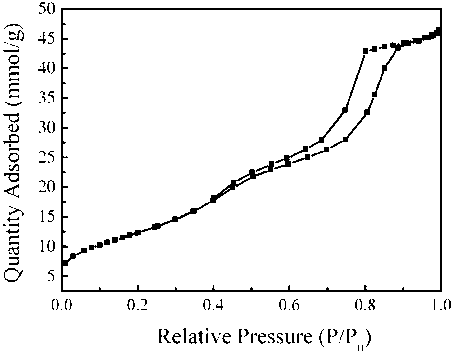

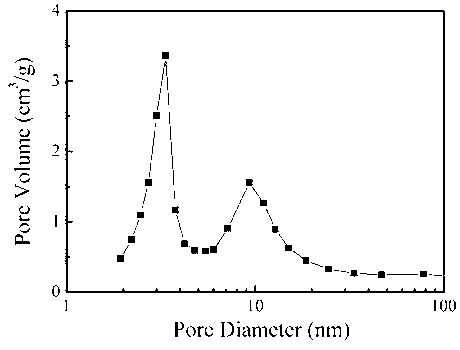

Embodiment 1

[0021] Take 5.0 g of sucrose, dissolve it in 60 mL of concentrated ammonia water, place the solution in a polytetrafluoroethylene-lined hydrothermal reaction kettle, react at 160 °C for 24 hours, and dry at 120 °C for 24 hours to obtain the precursor. The nitrogen content is 18.9%. Take 1.0 g of the above precursor, dissolve it in 2.0 g of absolute ethanol, add it dropwise on the surface of SBA-15 mesoporous molecular sieve at room temperature, and dry it under vacuum at 80 °C for 6 hours. Repeat the above steps, the amount of precursor is 0.8 g, and the amount of absolute ethanol is 1.6 g, to obtain the precursor / SBA-15 molecular sieve composite. The above compound was placed in an atmosphere tube furnace, and under the protection of argon, the temperature was raised to 350 °C at a rate of 1 °C / min, calcined for 2 hours, and then heated to 950 °C at a rate of 2 °C / min, and pyrolyzed for 2 hours. Cool to room temperature under the protection of argon atmosphere, soak in 30 mL...

Embodiment 2

[0024] Take 5.0 g of sucrose, dissolve it in 50 mL of concentrated ammonia water, place the solution in a polytetrafluoroethylene-lined hydrothermal reaction kettle, react at 180 °C for 18 hours, and dry at 120 °C for 24 hours to obtain the precursor. The nitrogen content is 17.4%. Take 1.0 g of the above precursor, dissolve it in 2.0 g of absolute ethanol, add it dropwise on the surface of SBA-15 mesoporous molecular sieve at room temperature, and dry it under vacuum at 80 °C for 6 hours. Repeat the above steps, the amount of precursor is 0.8 g, and the amount of absolute ethanol is 1.6 g, to obtain the precursor / SBA-15 molecular sieve composite. The above compound was placed in an atmosphere tube furnace, and under the protection of argon, the temperature was raised to 375 °C at a rate of 1.5 °C / min, calcined for 2 hours, and then heated to 800 °C at a rate of 3.5 °C / min, and pyrolyzed for 2 hours. Cool to room temperature under the protection of argon atmosphere, soak in 3...

Embodiment 3

[0027] Take 5.0 g of sucrose, dissolve it in 40 mL of concentrated ammonia water, place the solution in a polytetrafluoroethylene-lined hydrothermal reaction kettle, react at 200 °C for 12 hours, and dry at 120 °C for 24 hours to obtain the precursor. The nitrogen content is 16.7%. Take 1.0 g of the above precursor, dissolve it in 2.0 g of absolute ethanol, add it dropwise on the surface of SBA-15 mesoporous molecular sieve at room temperature, and dry it under vacuum at 80 °C for 6 hours. Repeat the above steps, the amount of precursor is 0.8 g, and the amount of absolute ethanol is 1.6 g, to obtain the precursor / SBA-15 molecular sieve composite. The above compound was placed in an atmosphere tube furnace, and under the protection of argon, the temperature was raised to 400 °C at a rate of 2 °C / min, calcined for 2 hours, and then heated to 650 °C at a rate of 5 °C / min, and pyrolyzed for 2 hours. Cool to room temperature under the protection of argon atmosphere, soak in 5% HF...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com