Rust removing composition

A technology of composition and mixture, applied in the direction of anti-corrosion composition, detergent composition, organic cleaning composition, etc., can solve the problems of slow rust removal speed and rust removal rate, achieve easy dilution, prevent secondary rust and corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0044] A: Experimental steps to determine the rust removal rate .

[0045] Experiments to determine the rust removal rate were carried out using tinplate. The tinplate was cut into 3 cm x 3 cm slices, and both sides of the slice were rubbed and polished using sandpaper. The tinplate slices were then kept in a salt spray box (ASTM B117) for 48 hours, so that rust layers appeared on both sides.

[0046] The composition described in Table 1 below was diluted seven times with water, and then the treated tinplate chips were soaked in the diluted solution for 15 minutes.

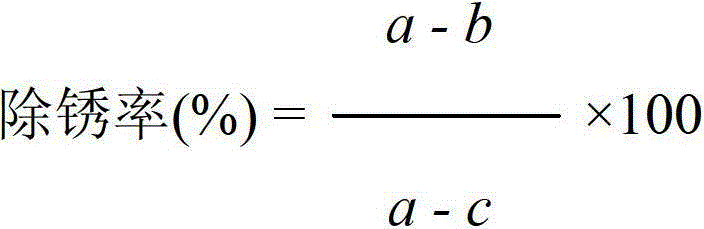

[0047] The rust removal rate (%) is expressed by the following formula:

[0048]

[0049] in:

[0050] The weight (g) of the tinplate slice that a=adheres to rust before derusting;

[0051] b = weight (g) of tinplate slices after derusting with rust remover, washing with water and drying;

[0052] c = weight of tinplate slices before rusting (g).

[0053] The higher the value of the rust removal rate, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com