Tin-oxide coated and vanadium-doped lithium iron phosphate material and preparation method thereof

A lithium iron phosphate and tin oxide technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of poor high temperature cycle stability, poor electrical conductivity, low tap density, etc., and achieve high tap and compaction density and low internal resistance. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

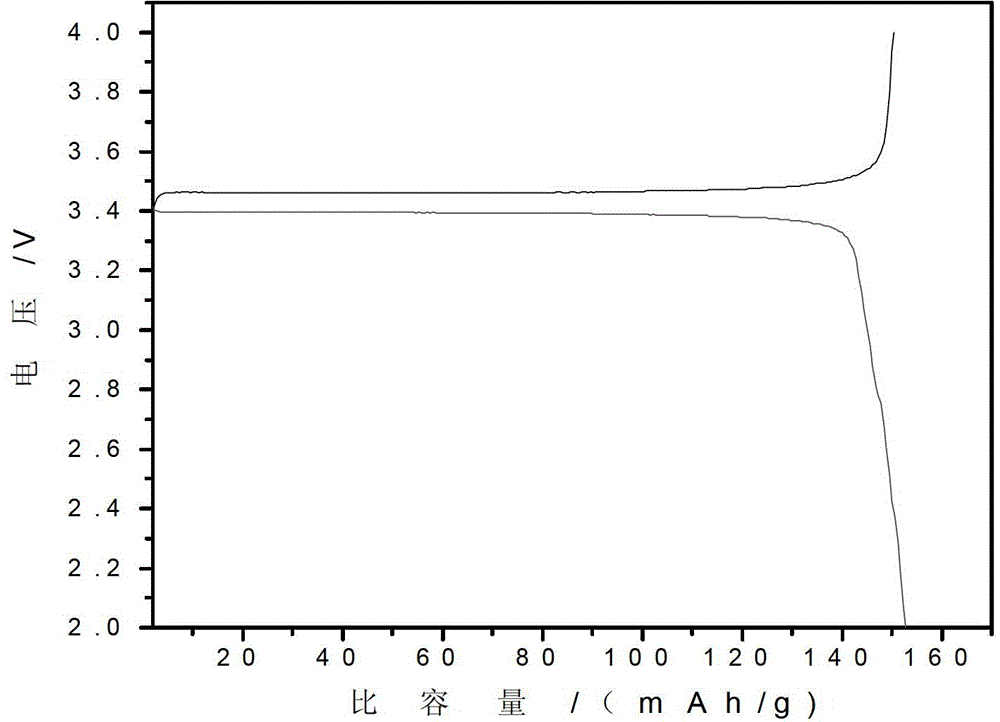

Embodiment 1

[0028] 4.7g ammonium metavanadate (NH 4 VO 3 ) and 21g tin tetrachloride (SnCl 4 ), dissolved in 100mL water to form a solution; the obtained solution was fully mixed with 360g ferrous oxalate, 230g ammonium dihydrogen phosphate and 74g lithium carbonate, ball milled, and dried to obtain a precursor material; the precursor material was finely crushed And heated to 680°C at a heating rate of 2°C / min under a nitrogen protective atmosphere, held for 12 hours, and cooled with the furnace to obtain lithium iron phosphate products, which were crushed by airflow to obtain tin oxide-coated vanadium-doped iron phosphate lithium material.

[0029] The obtained vanadium-doped tin oxide-coated lithium iron phosphate composite material was observed by scanning electron microscope, and the results were as follows: figure 1 shown. From figure 1 It can be seen that the primary particle size of the obtained vanadium-doped tin oxide-coated lithium iron phosphate composite material is 200-...

Embodiment 2

[0033] 3.64g vanadium pentoxide (V 2 o 5) and 21g tin tetrachloride (SnCl 4 ), dissolved in 100mL of water to form a solution; the obtained solution was fully mixed with 160g of iron oxide, 230g of ammonium dihydrogen phosphate and 74 grams of lithium carbonate, ball milled, and dried to obtain the precursor material. Heating at a heating rate of 3°C / min to 730°C, holding the temperature for 8 hours, and cooling with the furnace, the lithium iron phosphate product was obtained, and after jet crushing, a tin oxide-coated vanadium-doped lithium iron phosphate material was obtained.

Embodiment 3

[0035] 3g vanadium trioxide (V 2 o 3 ) and 10.8g of stannous oxide (SnO) were dissolved in 100mL of water using oxalic acid to form a solution; the obtained solution was fully mixed with 156g of iron oxide, 230g of ammonium dihydrogen phosphate and 74g of lithium carbonate, ball milled, and dried to obtain a precursor Materials, after fine crushing, in nitrogen-hydrogen mixed atmosphere with 3

[0036] The heating rate of ℃ / min is heated to 730 ℃, kept for 8 hours, and cooled with the furnace to obtain the lithium iron phosphate product. After jet crushing, the tin oxide-coated vanadium-doped lithium iron phosphate material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com