Preparation method of porous nickel titanium shape memory alloy

A memory alloy and porous nickel technology, which is applied in the field of preparation of porous nickel-titanium shape memory alloy, can solve the problems of short process and low cost, and achieve the effects of controllable pore structure, low cost, simple, stable and efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

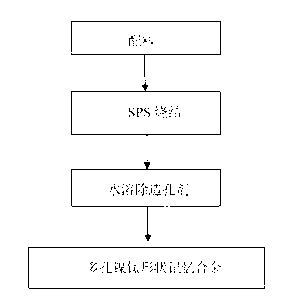

Method used

Image

Examples

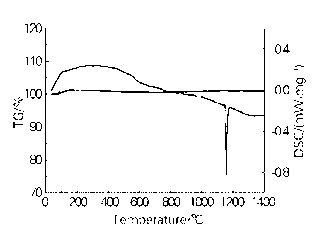

Embodiment 1

[0038] (1) First determine the volume V of the porous nickel-titanium shape memory alloy as required 总 (Using a mold with an inner diameter of Φ20mm x a height of 40mm, V 总 =12.56cm 3 ) and porosity of 40%, and then calculate the mass m of each raw material according to the following formula, weigh Ni powder with a particle size of 21-44 μm and a purity of 98.8-99.9%, and Ti powder with a particle size of 21-44 μm and a purity of 99.5-99.9% and SrSO 4 (The melting point is higher than 750°C, and thermal decomposition does not occur within the SPS sintering temperature range, the particle size is 75-150 μm, and the purity is ≥98%), and mixed for 40 minutes:

[0039] (1)

[0040] (2)

[0041] (3)

[0042] (4)

[0043] (5)

[0044] (6)

[0045] In the formula, V represents volume; ρ represents density; m represents ...

Embodiment 2

[0050] (1) First determine the volume V of the porous nickel-titanium shape memory alloy as required 总 (Using a mold with an inner diameter of Φ10mm×a height of 25mm, V 总 =1.96cm 3 ) and porosity of 60%, and then calculate the mass m of each raw material according to the following formula, weigh Ni powder with a particle size of 21-44 μm and a purity of 98.8-99.9%, and Ti powder with a particle size of 21-44 μm and a purity of 99.5-99.9% and analytically pure K 2 CO 3 (The melting point is higher than 750°C, and no thermal decomposition occurs within the SPS sintering temperature range, the particle size is 200-400μm, and the purity is ≥98%), and mixed for 150min:

[0051] (1)

[0052] (2)

[0053] (3)

[0054] (4)

[0055] (5)

[0056] (6)

[0057] In the formula, V represents volume; ρ represents density; m re...

Embodiment 3

[0062] (1) First determine the volume V of the porous nickel-titanium shape memory alloy as required 总 (Using a mold with an inner diameter of Φ20mm x a height of 40mm, V 总 =12.56cm 3 ) and porosity of 70%, and then calculate the mass m of each raw material according to the following formula, weigh Ni powder with a particle size of 21-44 μm and a purity of 98.8-99.9%, and Ti powder with a particle size of 21-44 μm and a purity of 99.5-99.9% and BaC 2 (The melting point is higher than 750°C, and thermal decomposition does not occur within the SPS sintering temperature range, the particle size is 300-1000μm, and the purity is ≥98%), and mixed for 30 minutes:

[0063] (1)

[0064] (2)

[0065] (3)

[0066] (4)

[0067] (5)

[0068] (6)

[0069] In the formula, V represents volume; ρ represents density; m represents ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com