High-strength magnetic calcium-phosphate-based bone cement and preparation method thereof

A calcium phosphate, high-strength technology, applied in medical science, prosthesis, etc., can solve the problems of high bone cement preparation process requirements, prone to danger, low mechanical strength, etc., and achieve good injectability, safe operation, and easy preparation The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

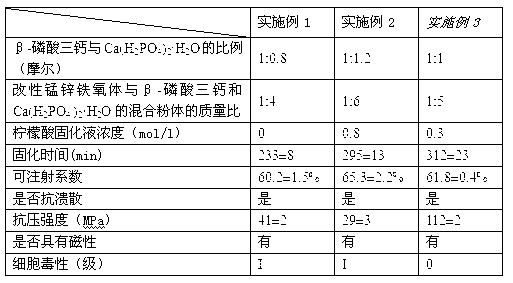

Examples

preparation example Construction

[0031] The preparation method of the high-strength magnetic calcium phosphate-based bone cement comprises the following steps:

[0032] 1) Preparation of manganese zinc ferrite

[0033] 1) According to Mn 0.4 Zn 0.6 Fe 2 o 4 The stoichiometric ratio weighs FeCl 3 ·6H 2 O, ZnCl 2 and MnCl 2 4H 2 O is made into a mixture, and ultrapure water is added to make a solution with a total concentration of metal ions of 0.3mol / L, and the reaction is carried out at a constant temperature of 90°C for 4 hours;

[0034] During the reaction, under the condition of strong stirring, the NaOH solution with a concentration of 1mol / L was added dropwise to the solution to control the pH value of the reaction solution to be 9.5-10.5;

[0035] The strong stirring here is mainly to dissipate the heat generated by the reaction, and stir at a stirring speed of 3000rpm in actual operation;

[0036] 2) Wash the reaction solution and the generated precipitate in step 1), centrifuge, and vacu...

Embodiment 1

[0053] A preparation method of high-strength magnetic calcium phosphate-based bone cement, comprising the following steps:

[0054] 1) Preparation of manganese zinc ferrite

[0055] 1) According to Mn 0.4 Zn 0.6 Fe 2 o 4 The stoichiometric ratio weighs FeCl 3 ·6H 2 O, ZnCl 2 and MnCl 2 4H 2 O is made into a mixture, and ultrapure water is added to make a solution with a total concentration of metal ions of 0.3mol / L, and the reaction is carried out at a constant temperature of 90°C for 4 hours;

[0056] During the reaction, under the condition of strong stirring, the NaOH solution with a concentration of 1mol / L was added dropwise to the solution to control the pH value of the reaction solution to be 9.5-10.5;

[0057] 2) Wash the reaction solution and the generated precipitate in step 1), centrifuge, and vacuum-dry at 60°C to obtain the manganese-zinc-ferrite precursor, which is set aside;

[0058] 3) Calcining the manganese-zinc-ferrite precursor obtained in step...

Embodiment 2

[0068] A preparation method of high-strength magnetic calcium phosphate-based bone cement, comprising the following steps:

[0069] 1) Preparation of manganese zinc ferrite, as in Example 1;

[0070] 2) Preparation of solid phase mixture

[0071] Weigh β-tricalcium phosphate and Ca(H 2 PO 4 ) 2 ·H 2 O powder is put into mortar and grinds 15min, makes mixed powder, for subsequent use;

[0072] Take the modified manganese zinc ferrite powder prepared in step 1) and the mixed powder prepared in step 2) according to the weight ratio of 1: 6, mix them in a mortar and grind for 15 minutes, and mix them evenly to obtain a solid phase mixture ,spare;

[0073] c) Liquid phase preparation

[0074] Preparation concentration is that the citric acid solution of 0.8mol / L is standby as liquid phase;

[0075] 4) Solid phase mixture and liquid phase reconciliation

[0076] Add the citric acid solution in step 3) to the solid phase mixture prepared in step 2) according to the rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com