Foamed water glass expanded perlite thermal insulating board

A technology of expanded perlite and foamed water, which is applied in the field of foamed water glass expanded perlite insulation board and its preparation, can solve the problems of poor water resistance, low bonding strength and long curing time of pure water glass binder, Achieve the effects of good thermal insulation performance, low price and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] The composition of the present example inorganic binder raw material is as follows:

[0018] Sodium water glass 33.95% Potassium silicate 39.30% Silica sol 7.32% Silicone waterproofing agent NYY 2.05% Vinyltriethoxysilane Aqueous solution of acetic acid (pH=5) 4.03% High aluminum powder 11.92% rosin 1.46%

[0019] The preparation process is as follows:

[0020] 1. Mix sodium water glass and potassium water glass in a water bath and heat at 80°C with a stirring speed of 1000 rpm, and stir for 15 minutes to heat and age for modification. Cool to room temperature and set aside.

[0021] 2. Add silica sol and stir for 5 minutes.

[0022] 3. Slowly add waterproofing agent and stabilizer, and stir for 25 minutes.

[0023] 4. Add high alumina powder and cement foaming agent, stir for 20 minutes, (step 2-4 water bath heating temperature is 50 ℃, and the speed is 1000 rpm);

[0024] 5. Pour out, mix and stir with expande...

example 2

[0027] Sodium water glass 45.95% Potassium silicate 23.30% Silica sol 5.32% Sodium methyl silicate 2.95% Vinyltriethoxysilane Acetic acid aqueous solution (pH=3.2) 4.95% High aluminum powder 14.72% Hydrogen peroxide foaming agent 2.56%

[0028] The preparation process is as follows:

[0029] 1. Sodium water glass and potassium water glass were mixed and stirred for 15 minutes for heating and aging modification. The whole preparation process was heated in a water bath at 80° C., and the stirring speed was 1000 rpm. Cool to room temperature and set aside.

[0030] 2. Heat and stir the modified water glass in a water bath, add silica sol, and stir for 5 minutes.

[0031] 3. Slowly add waterproofing agent and stabilizer, and stir for 25 minutes.

[0032] 4. Add high alumina and then drop hydrogen peroxide foaming agent, stir for 20 minutes, (step 2-4 water bath heating temperature is 60 ℃, and the speed is 1000 rpm)

[0033] 5...

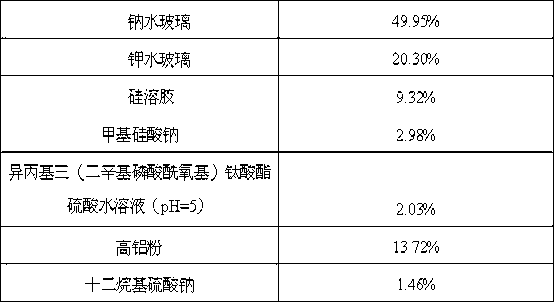

example 3

[0037] Sodium water glass 49.95% Potassium silicate 20.30% Silica sol 9.32% Silicone Water Repellent 2.98% KH560 Oxalic Acid Aqueous Solution (pH=5) 2.03% talcum powder 14.72% rosin 1.46%

[0038] The preparation process is as follows:

[0039] 1. Mix sodium water glass and potassium water glass and stir for 15 minutes to heat and age for modification. Heat in a water bath to 65°C, and the stirring speed is 1000 rpm. Cool to room temperature and set aside.

[0040] 2. Heat the modified water glass in a water bath and stir; add silica sol and stir for 5 minutes.

[0041] 3. Slowly add waterproofing agent and stabilizer, and stir for 25 minutes.

[0042] 4. Add talcum powder and rosin foaming agent, stir for 20 minutes, (step 2-4 water bath heating temperature is 70 ℃, speed is 1200 rpm), then pour it out, mix with expanded perlite 0.83:1, Pressing.

[0043] 5. Put it in the oven, dry at 150°C for 2.5 hours and take it out....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com