High-concentration erbium ion doped tellurium tungstate glass capable of emitting light at mid-infrared 2.7 microns

A technology of tellurtungstate and erbium ions, which is applied in the field of high-concentration erbium ion-doped mid-infrared 2.7μm luminescent tellurungstate glass, can solve the problems that have not been reported, and achieve high doping concentration and infrared transmittance. High, excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Composition as in Table 1 1 # As shown, the specific preparation process is as follows:

[0029] According to table 1 in 1 # The mole percentage of the glass composition, calculate the corresponding weight of each composition, weigh the raw materials and mix them uniformly; put the mixture into a corundum crucible and melt it in a silicon carbide rod electric furnace at 1200 ° C, and clarify it for 15 minutes after the mixture is completely melted. Minutes, pour the molten glass into the preheated mold; quickly move the glass into a muffle furnace that has been heated to 420°C, keep it warm for 10 hours, then lower it to room temperature at a rate of 10°C / hour, and take out the glass after cooling completely sample.

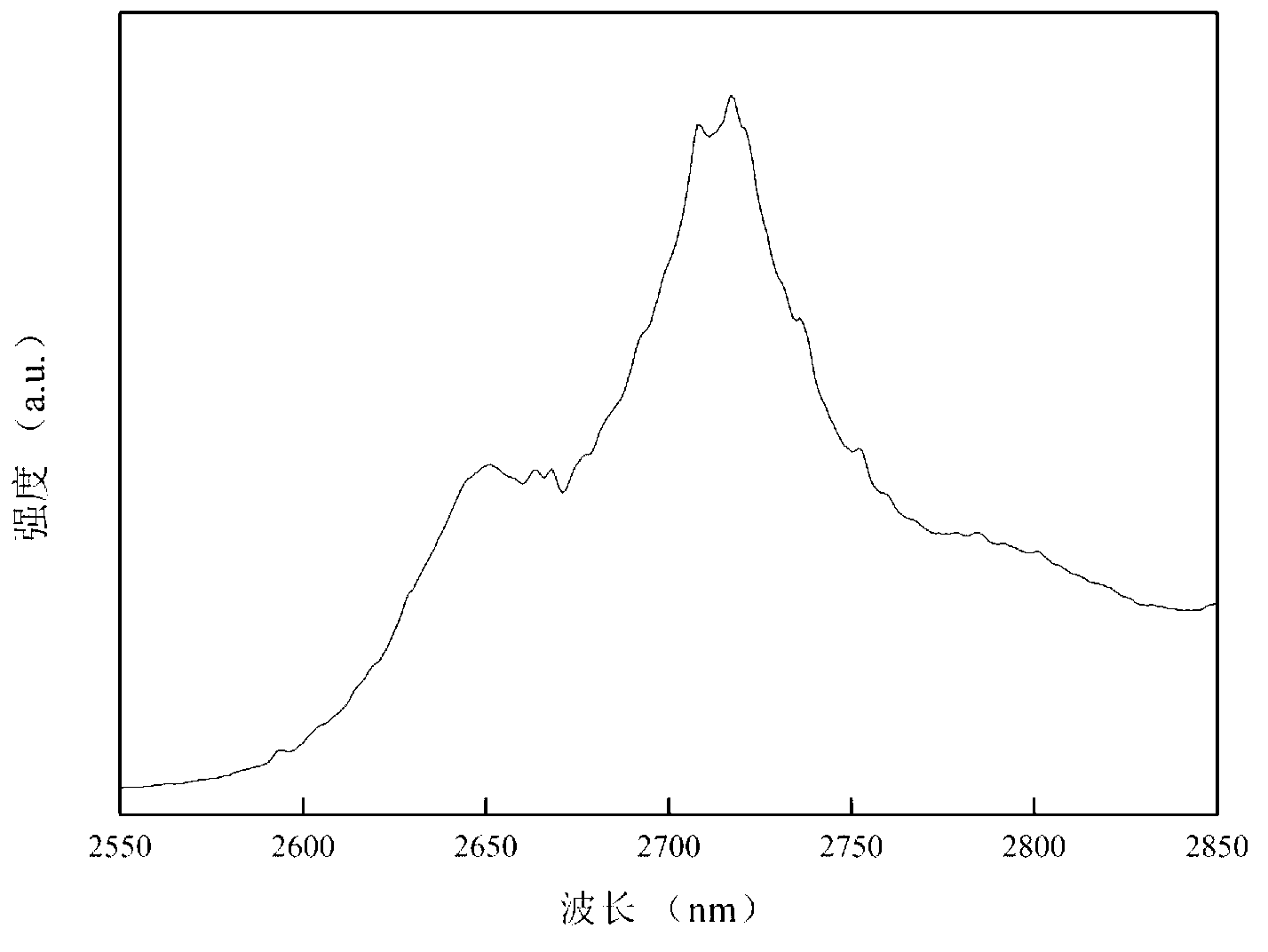

[0030] The test results for this glass are as follows:

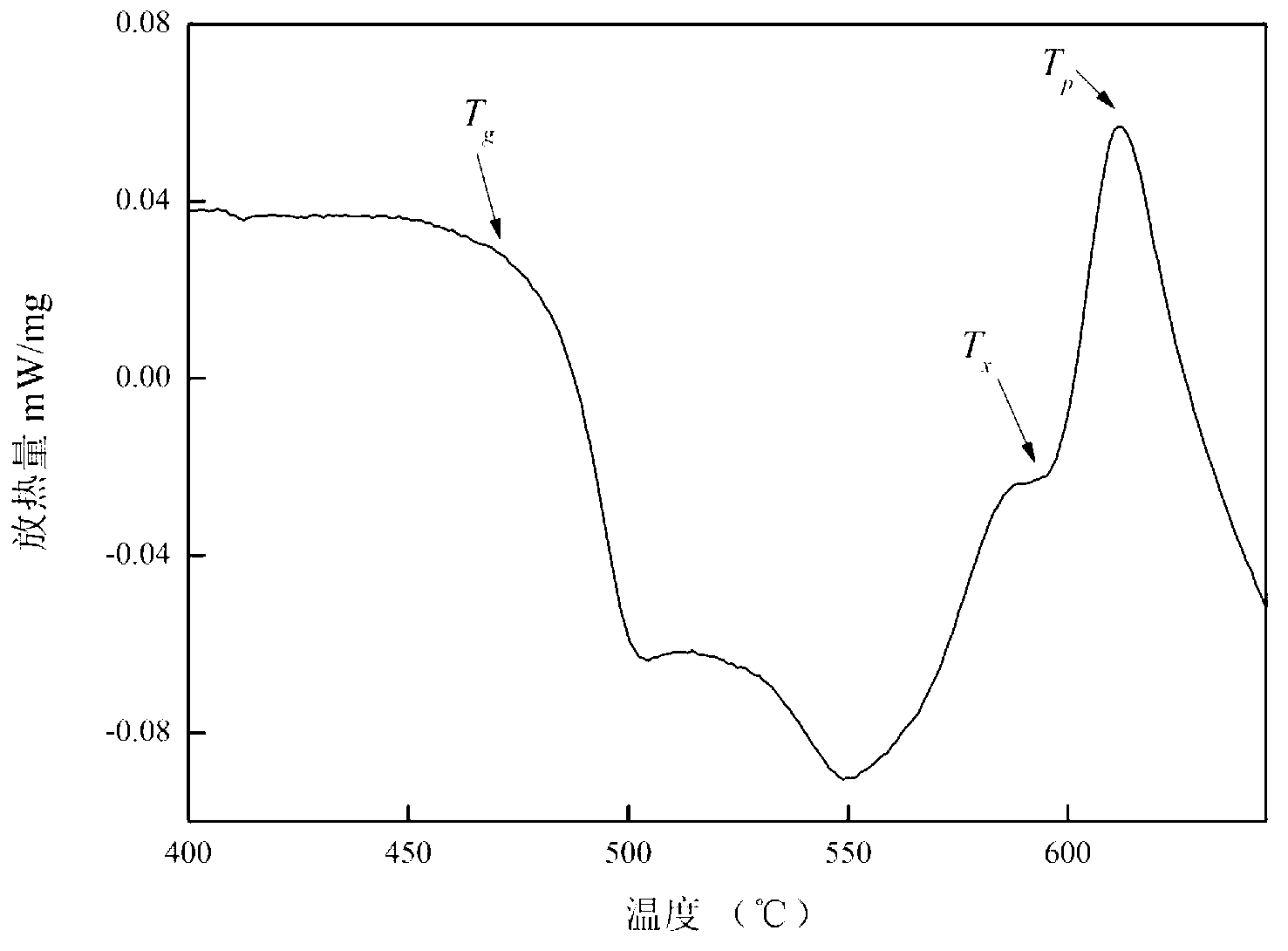

[0031] Take a small sample after annealing, grind it into a fine powder with an agate mortar, and conduct a differential thermal analysis test. The differential thermal curve of the mid-infrared ...

Embodiment 2

[0034] Composition as in Table 1 2 # As shown, the specific preparation process is as follows:

[0035] According to table 1 in 2 # The mole percentage of the glass composition, calculate the corresponding weight of each composition, weigh the raw materials and mix them uniformly; put the mixture into a corundum crucible and melt it in a silicon carbide rod electric furnace at 1200 ° C, and clarify it for 15 minutes after the mixture is completely melted. Minutes, pour the molten glass into the preheated mold; quickly move the glass into a muffle furnace that has been heated to 420°C, keep it warm for 10 hours, then lower it to room temperature at a rate of 10°C / hour, and take out the glass after cooling completely sample.

[0036] The test results for this glass are as follows:

[0037] Take a small sample after annealing, grind it into a fine powder with an agate mortar, and conduct a differential thermal analysis test.

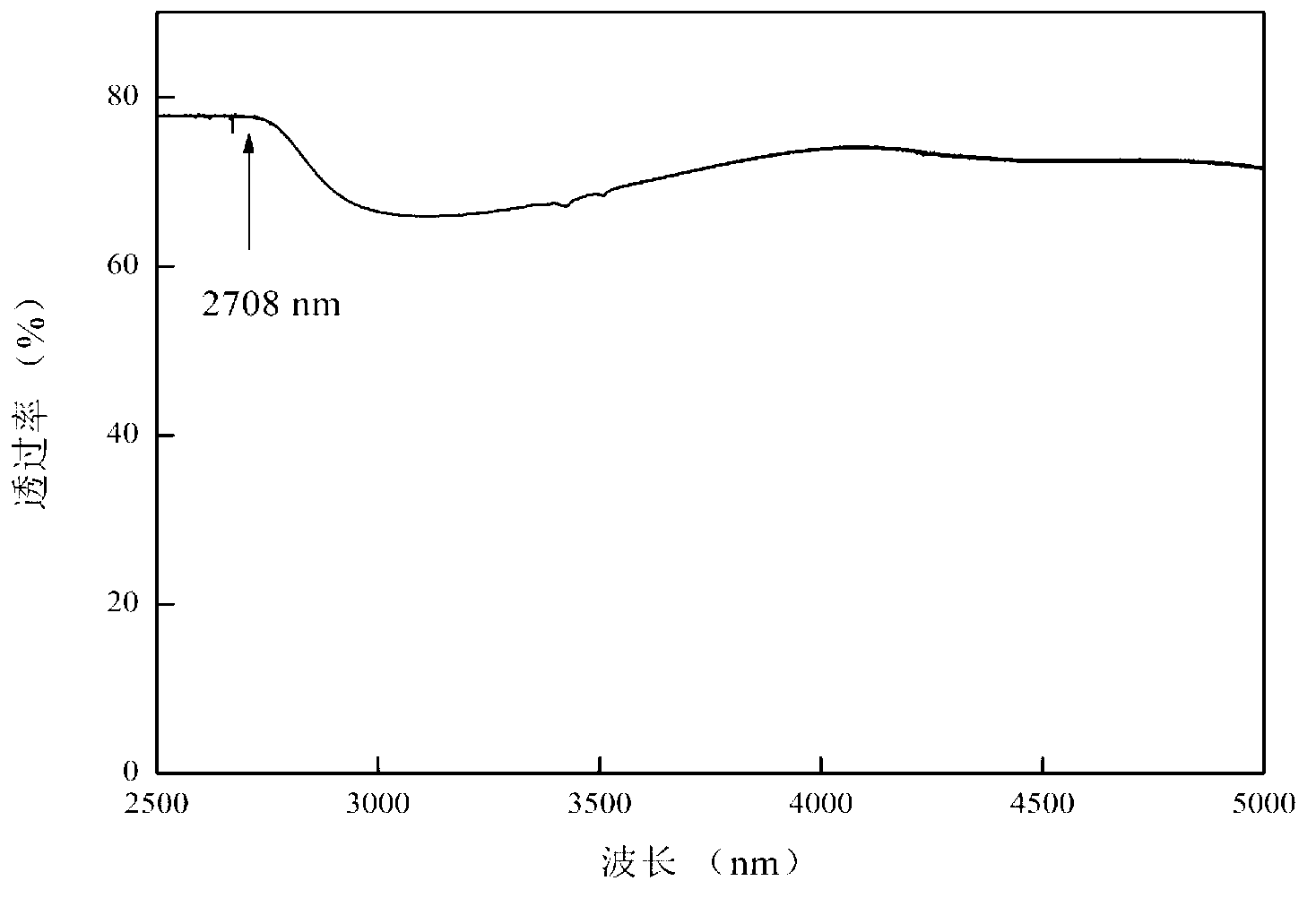

[0038] Process the annealed sample into a 20×10×1...

Embodiment 3

[0040] Composition as in Table 1 3 # As shown, the specific preparation process is as follows:

[0041] According to table 1 in 3 # The mole percentage of the glass composition, calculate the corresponding weight of each composition, weigh the raw materials and mix them uniformly; put the mixture into a corundum crucible and melt it in a silicon carbide rod electric furnace at 1200 ° C, and clarify it for 15 minutes after the mixture is completely melted. Minutes, pour the molten glass into the preheated mold; quickly move the glass into a muffle furnace that has been heated to 420°C, keep it warm for 10 hours, then lower it to room temperature at a rate of 10°C / hour, and take out the glass after cooling completely sample.

[0042] The test results for this glass are as follows:

[0043] Take a small sample after annealing, grind it into a fine powder with an agate mortar, and conduct a differential thermal analysis test.

[0044] Process the annealed sample into a 20×10×1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com