Backplane for solar energy assembly and preparation method thereof

A solar backsheet and composition technology, applied in chemical instruments and methods, synthetic resin layered products, photovoltaic power generation, etc., can solve problems such as poor moisture and heat aging resistance, unguaranteed adhesion, and easy embrittlement, etc., to achieve The preparation method is simple and easy, the effect of excellent interlayer peeling force and low water vapor transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

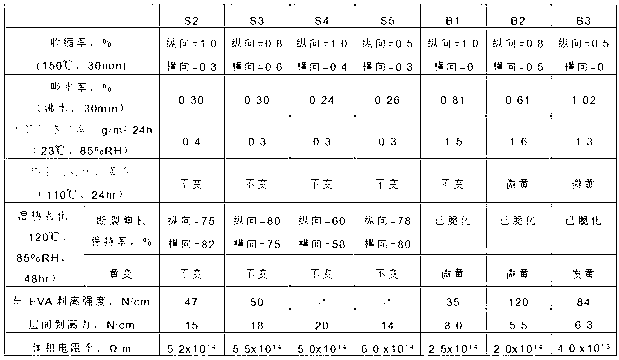

Examples

Embodiment 1

[0059] A modified polyethylene resin composition, its preparation method is as follows:

[0060] (1) Preparation of grafted polyethylene PE-MA

[0061] 100 parts (parts by mass) of LLDPE7042 (Beijing Yanshan Petrochemical Company), 1 part of maleic anhydride (chemical reagent, analytical grade), and 0.05 parts of DCP initiator (Tianjin Aksu Company) were measured and added to the mixer for mixing and homogenization. After homogenizing for two hours, put it into a twin-screw extruder for melt extrusion and granulation; cool and granulate to obtain granular grafted polyethylene PE-MA, and its melt flow rate at 190°C / 2.16kg is 0.5g / 10min. The diameter of the screw is 75mm, the aspect ratio is 33, the temperature of the screw is controlled at 160-220°C, the rotational speed of the screw is controlled at 100 rpm, and the residence time of the material in the screw is 2-4 minutes.

[0062] The LLDPE7042 (Beijing Yanshan Petrochemical Company) is a linear low-density polyethylene wi...

Embodiment 2

[0066] A kind of solar back plate, its preparation method is as follows:

[0067] (1) Preparation of inner and surface materials: Add 100 parts of polyhexamethylene dodecamide (PA612) into the dryer, dry at 80°C for 4 hours, put it into a high mixer, add 20 parts of rutile titanium dioxide R960, 0.2 parts of antioxidant tetrakis[?-(3',5'-di-tert-butyl-4'-hydroxyphenyl) propionate] pentaerythritol ester, 0.2 parts of UV absorber 2-hydroxy-4-n-octyloxy Benzophenone, 0.1 part of light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, stirred for 30 minutes at a speed of 600 rpm, and mixed the materials evenly; Then put the above-mentioned materials into the A screw rod of the three-layer co-extruded sheet material unit, the screw rod diameter is 60 mm, and the length-to-diameter ratio is 33.

[0068] (2) Preparation of core layer material: Put the finished product S1 prepared in Example 1 into the B screw of the three-layer co-extrusion sheet unit, the screw diameter i...

Embodiment 3

[0072] A kind of solar back plate, its preparation method is as follows:

[0073] (1) Preparation of inner and surface materials: Add 100 parts of polydecanediamide sebacamide (PA1010) into the dryer, dry at 80°C for 4 hours and put it into a high mixer, add 20 parts of rutile titanium dioxide R960, 0.2 parts Antioxidant tetrakis[?-(3',5'-di-tert-butyl-4'-hydroxyphenyl)propionate]pentaerythritol ester, 0.2 parts of UV absorber 2-hydroxy-4-n-octyloxydiphenyl Methanone, 0.1 part of light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, stirred for 30 minutes at a speed of 600 rpm, and mixed the materials evenly; then The above-mentioned materials are put into the A screw of the three-layer co-extruded sheet material unit, the diameter of the screw is 60 mm, and the aspect ratio is 33.

[0074] (2) Preparation of core layer material: Put the finished product S1 prepared in Example 1 into the B screw of the three-layer co-extrusion sheet unit, the screw diameter is 90 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com