Preparation method for improving positive electrode material LiCoO2 electrical performance

A technology of positive electrode material and electrical performance, which is applied in the field of preparation of lithium cobalt oxide conductivity modification for lithium ion battery positive electrode material, can solve the problems of low capacity, inability to realize high-rate charge and discharge, poor conductivity, etc., and achieve high capacity, Superior rate charge and discharge performance, excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

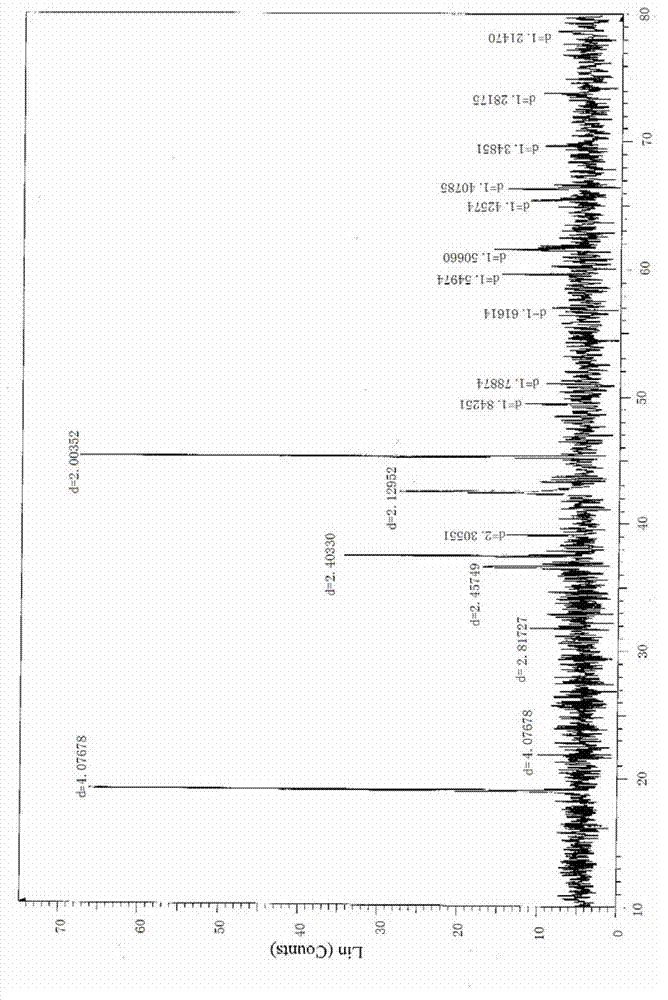

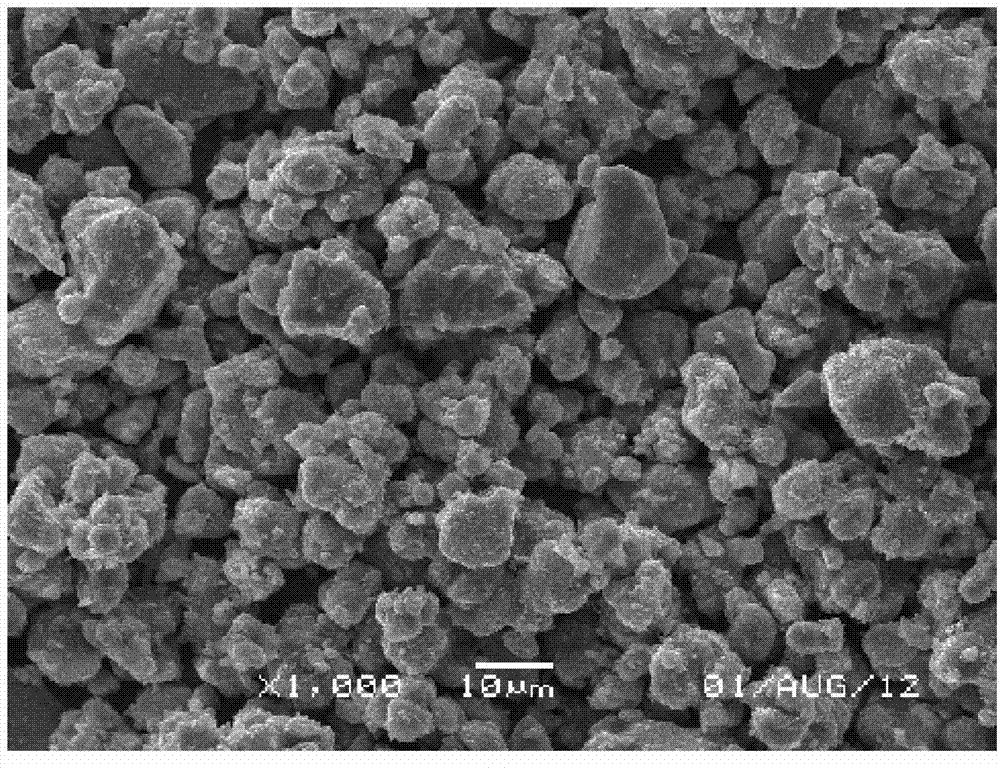

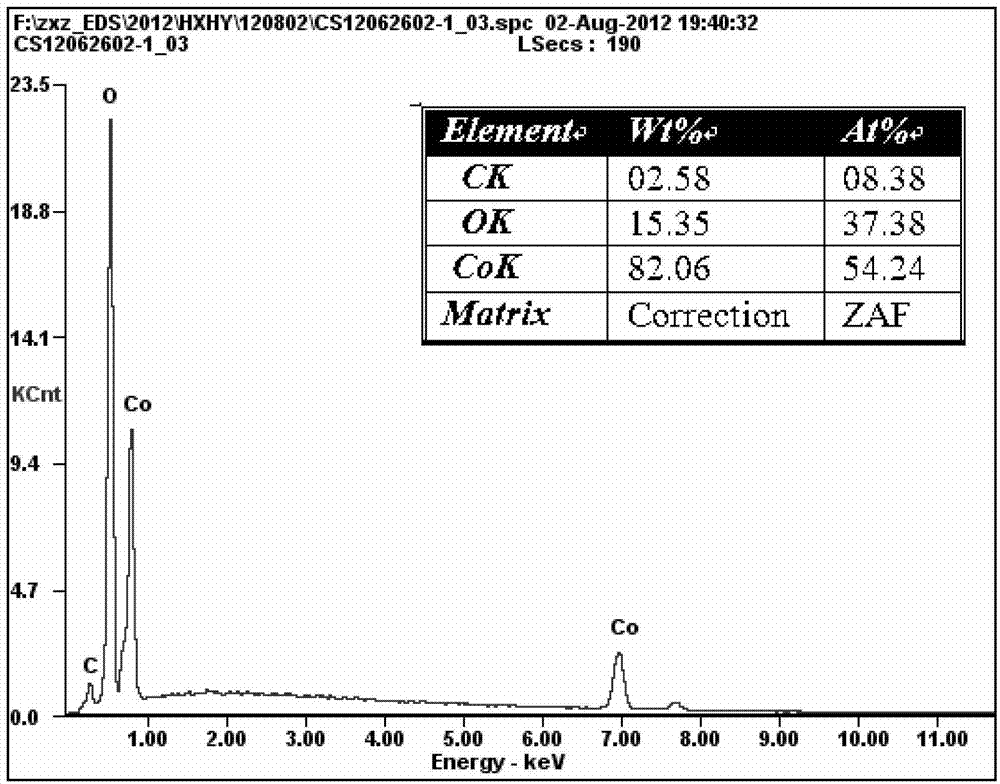

[0021] Example 1: An improved cathode material LiCoO 2 The preparation method of electrical properties is characterized in that: it is completed according to the following steps:

[0022] 1) Select battery-grade lithium carbonate from Sichuan Tianqi Lithium Industry Co., Ltd. and GB-100 model cobalt tetroxide from Ningbo Kebot Cobalt and Nickel Co., Ltd. as raw materials, and make the ratio according to the molar ratio of lithium to cobalt 1.035:1. Add TiO 2 , ZrO 2 and Nb 2 o 5 As additive T1, where TiO 2 The added weight is 0.12% of the weight of tricobalt tetroxide, ZrO 2 The added weight is 0.1% of the weight of tricobalt tetroxide, Nb 2 o 5 The added weight of is 0.15% of the weight of tricobalt tetroxide. The battery-grade lithium carbonate, GB-100 model cobalt tetroxide, TiO 2 , ZrO 2 and Nb 2 o 5 Perform doping and mixing, and mix well.

[0023] 2) Put the uniformly mixed material obtained in 1) into a refractory sagger, push it into a high-temperature pus...

Embodiment 2

[0028] Example 2: An improved cathode material LiCoO 2 The preparation method of electrical properties is characterized in that: it is completed according to the following steps:

[0029] 1) Select battery-grade lithium carbonate from Sichuan Tianqi Lithium Industry Co., Ltd. and GB-100 model cobalt tetroxide from Ningbo Kebot Cobalt Nickel Co., Ltd. as raw materials, and mix according to the molar ratio of lithium to cobalt 1.045:1. Add TiO 2 , CeO 2 and Nb 2 o 5 As additive T1, where TiO 2 The added weight is 0.12% of the weight of tricobalt tetroxide, ZrO 2 The added weight is 0.1% of the weight of tricobalt tetroxide, Nb 2 o 5 The added weight of is 0.15% of the weight of tricobalt tetroxide. The battery-grade lithium carbonate, GB-100 model cobalt tetroxide, TiO 2 , ZrO 2 and Nb 2 o 5 Perform doping and mixing, and mix well.

[0030] 2) Put the homogeneously mixed material obtained in 1) into a refractory sagger, push it into a high-temperature pusher kiln, k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com