Hydrogenation method of C4 fraction containing rich alkynes and dialkenes

A technology for carbon four fractions and diolefins, which is applied in the field of selective hydrogenation of alkyne-rich residual materials, can solve the problems of harsh operating conditions, high catalyst selectivity requirements, losses, etc., and achieves improved operating time and long cycle The effect of stable operation and increased effective contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

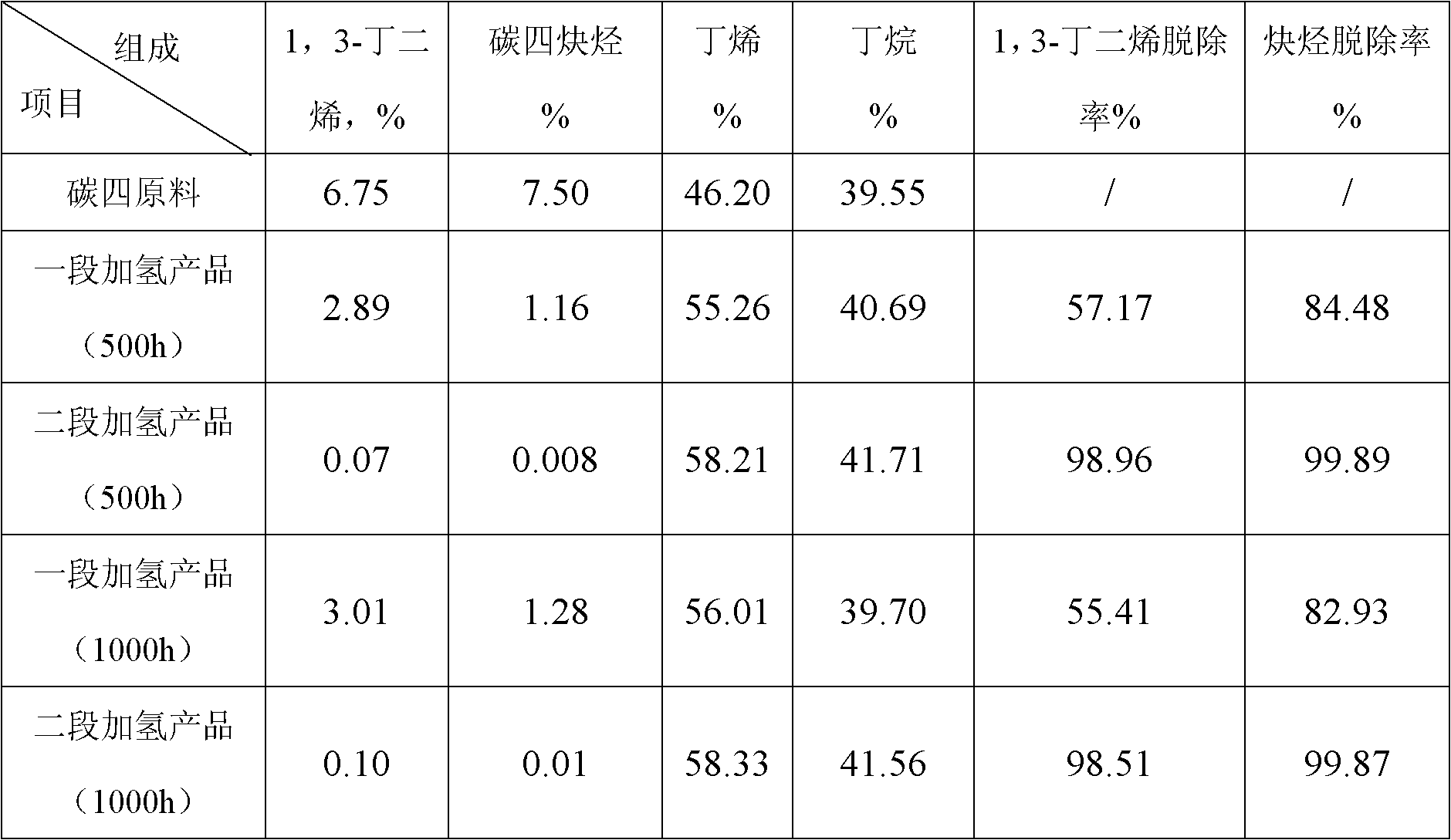

[0019] The raw material is the residual C4 material of butadiene extraction rich in alkyne and diene and the remaining C4 material of MTBE plant, the weight ratio of the remaining C4 material and the residual C4 material rich in alkyne and diene is 2: 1. The hydrogenation reactor adopts α-Al catalyst 2 o 3 Loading 0.2% palladium-based catalyst, and adding additives X1 (0.05% Au, 0.1% Ag and 1% Cu) and X2 (0.1% lanthanum); the reactor is a two-stage isothermal type in series Fixed bed, reactor inlet temperature is 30°C, reaction pressure is 1.5MPa, liquid hourly space velocity is 2.0h -1 The molar ratio of hydrogen to the total amount of alkynes and dienes in the first reactor is 1, and the molar ratio of hydrogen to the total amount of alkynes and dienes in the second reactor is 3. Table 1 is the composition of materials before and after the reaction .

[0020] Material composition before and after table 1 reaction

[0021]

Embodiment 2

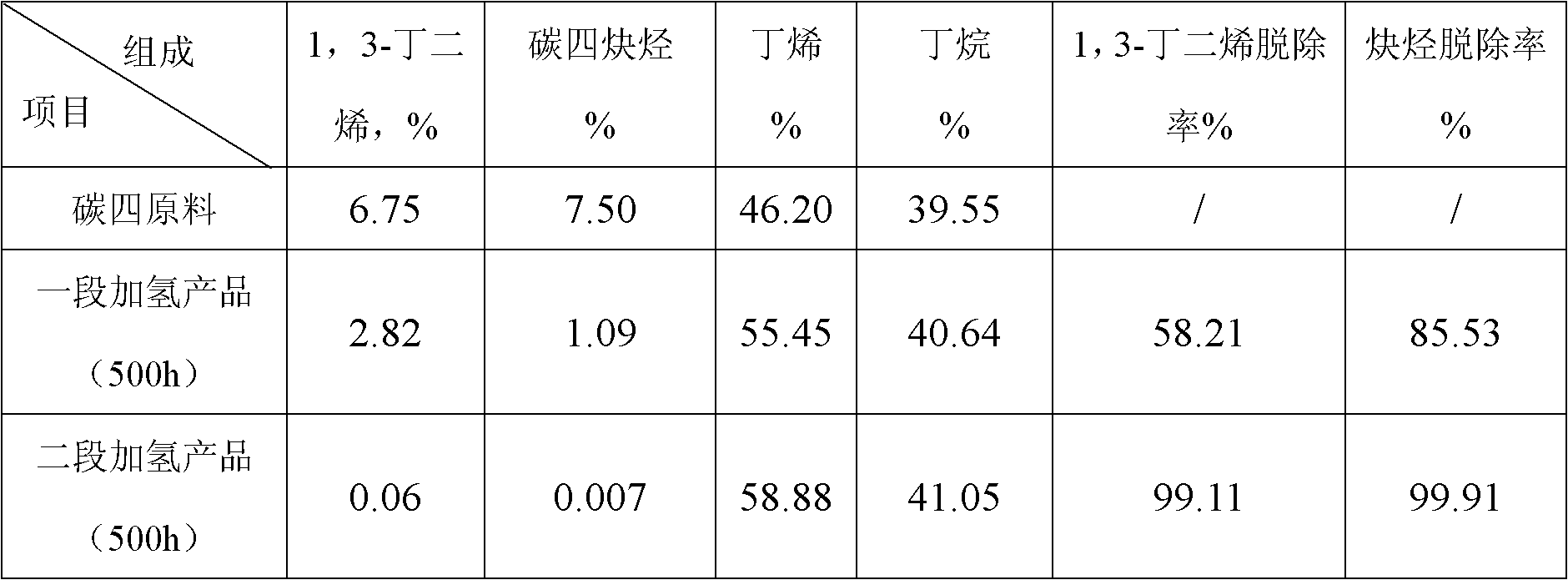

[0023] The raw material is the residual C4 material of butadiene extraction rich in alkyne and diene and the remaining C4 material of MTBE plant, the weight ratio of the remaining C4 material and the residual C4 material rich in alkyne and diene is 2: 1. The hydrogenation reactor adopts α-Al catalyst 2 o 3 Loaded with 0.2% palladium-based catalyst, and added promoters X1 (0.05% Au, 0.1% Ag and 1% Cu), X2 (0.1% Lanthanum) and X3 (0.2% Li and 0.1% K ); the reactor is two series-connected two-stage isothermal fixed beds, the reactor inlet temperature is 30°C, the reaction pressure is 1.5MPa, and the liquid hourly space velocity is 2.0h -1 The molar ratio of hydrogen to the total amount of alkynes and dienes in the first reactor is 1, and the molar ratio of hydrogen to the total amount of alkynes and dienes in the second reactor is 3. Table 2 is the composition of materials before and after the reaction .

[0024] Material composition before and after table 2 reaction

[0025...

Embodiment 3

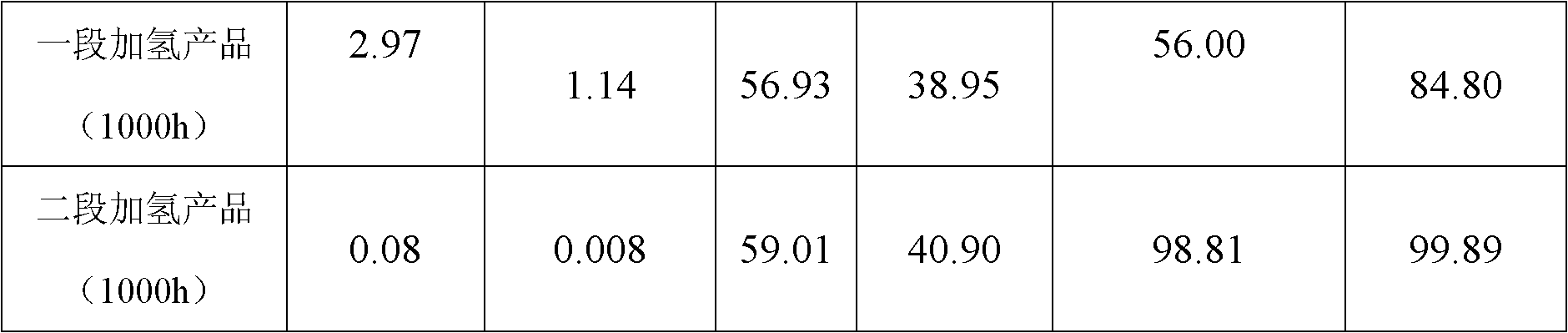

[0028] The raw material is the residual C4 material of butadiene extraction rich in alkyne and diene and the remaining C4 material of MTBE plant, the weight ratio of the remaining C4 material and the residual C4 material rich in alkyne and diene is 2: 1. The hydrogenation reactor adopts α-Al catalyst 2 o 3 A 15% copper-based catalyst was loaded with additives X1 (0.1% Au, 0.2% Ag), X2 (0.1% Lanthanum and 0.1% Ce) and X3 (0.2% Li, 0.2% K ); the reactor is two serially connected two-stage isothermal fixed beds, the inlet temperature of the reactor is 30°C, the reaction pressure is 1.5MPa, and the liquid hourly space velocity is 1.5h -1 The molar ratio of hydrogen to the total amount of alkynes and dienes in the first reactor is 1.5, and the molar ratio of hydrogen to the total amount of alkynes and dienes in the second reactor is 3. Table 3 is the composition of materials before and after the reaction .

[0029] Table 3 Composition of materials before and after reaction

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com