A kind of water-based two-component anti-icing and snow coating and production method thereof

An anti-icing and snow coating, water-based two-component technology, applied in the field of coatings, can solve the problems of low durability of coating anti-icing and snow performance, affecting the health of construction workers, and high VOC emissions, achieving low VOC emissions and stable storage. sex, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

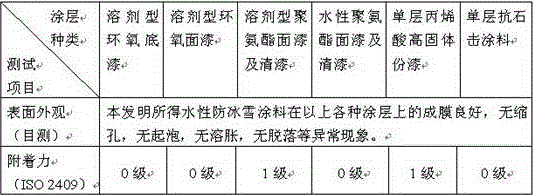

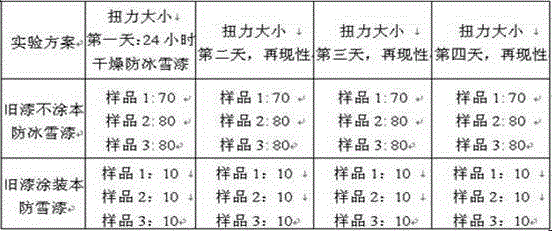

Examples

Embodiment 1

[0048] A water-based anti-icing and snow coating and a production method thereof, comprising the following process steps, the proportions of which are in parts by weight:

[0049] (1) Part A of main ingredient: Add 42 parts of acrylic polyol polymer aqueous emulsion (product of Nuplex Company) and 30 parts of polytetrafluoroethylene TF 5050 (product of 3M Company) in sequence under low-speed (300rpm) stirring, slowly in order (flowing down in thin lines) add 18 parts of deionized water and 0.2 parts of PH regulator AMP 95 organic amine, stir at high speed (800rpm) for 5 minutes; slowly (flowing down in thin lines) add non-ionic surfactant (BYK company product) 1.5 parts, and stirred at high speed (800rpm) for 5 minutes;

[0050] Pre-disperse 0.8 parts of IBA and Isoparaffin film-forming aid mixture under low-speed (300rpm) stirring and add to the previous emulsion, and disperse at high-speed (800rpm) for 5 minutes;

[0051] 6 parts of pre-dispersed film-forming aids DMM, DAA,...

Embodiment 2

[0057] A water-based anti-icing and snow coating and a production method thereof, comprising the following process steps, the proportions of which are in parts by weight:

[0058] (1) Part A of the main agent: Mix 28 parts of acrylic polyol polymer aqueous emulsion (Nuplex company product) and 26 parts of water-based hydroxyl polyacrylic acid dispersion (Bayer company product) with polytetrafluoroethylene TF 5050 under low speed (300rpm) stirring (product of 3M company) 27 parts are added in sequence, slowly (flowing down in a thin line) in order, add 10 parts of water and 0.1 part of PH regulator DMEA, stir at high speed (800rpm) for 5 minutes; slowly (flowing down in a thin line) add 0.5 parts of polyether modified silicone leveling agent (product of BYK company), and stir at high speed (800rpm) for 5 minutes;

[0059] Pre-disperse IBA and 0.8 parts of Isoparaffin film-forming aid mixture under low-speed (300rpm) stirring and add to the previous emulsion, and disperse at hig...

Embodiment 3

[0066] A water-based anti-icing and snow coating and a production method thereof, comprising the following process steps, the proportions of which are in parts by weight:

[0067] (1) Part A of the main agent: 70 parts of water-based hydroxyl polyacrylic acid dispersion (product of BAYER company) and 19 parts of polytetrafluoroethylene TF 5035 (product of 3M company) were added in sequence under low speed (500rpm) stirring, and slowly (formed) in order Thin line flowing down) add 5 parts of water and 0.02 part of PH regulator DMEA, stir at high speed (800rpm) for 5 minutes; slowly (flowing down in thin line) add polyether modified polydimethylsiloxane solution to wet the dispersant (BYK company product) 1.6 parts, and stir at high speed (800rpm) for 5 minutes;

[0068] Pre-disperse IBA and 0.8 parts of Isoparaffin film-forming aid mixture under low-speed (300rpm) stirring and add to the previous emulsion, and disperse at high-speed (800rpm) for 5 minutes;

[0069] Pre-dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com