Production method and application of immune globulin G

A technology of immunoglobulin and products, applied in the direction of immunoglobulin, immunoglobulin from serum, application, etc., can solve the problems of not being suitable for large-scale industrial production, small production scale, and cumbersome production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0135] small amount of immunoglobulin G

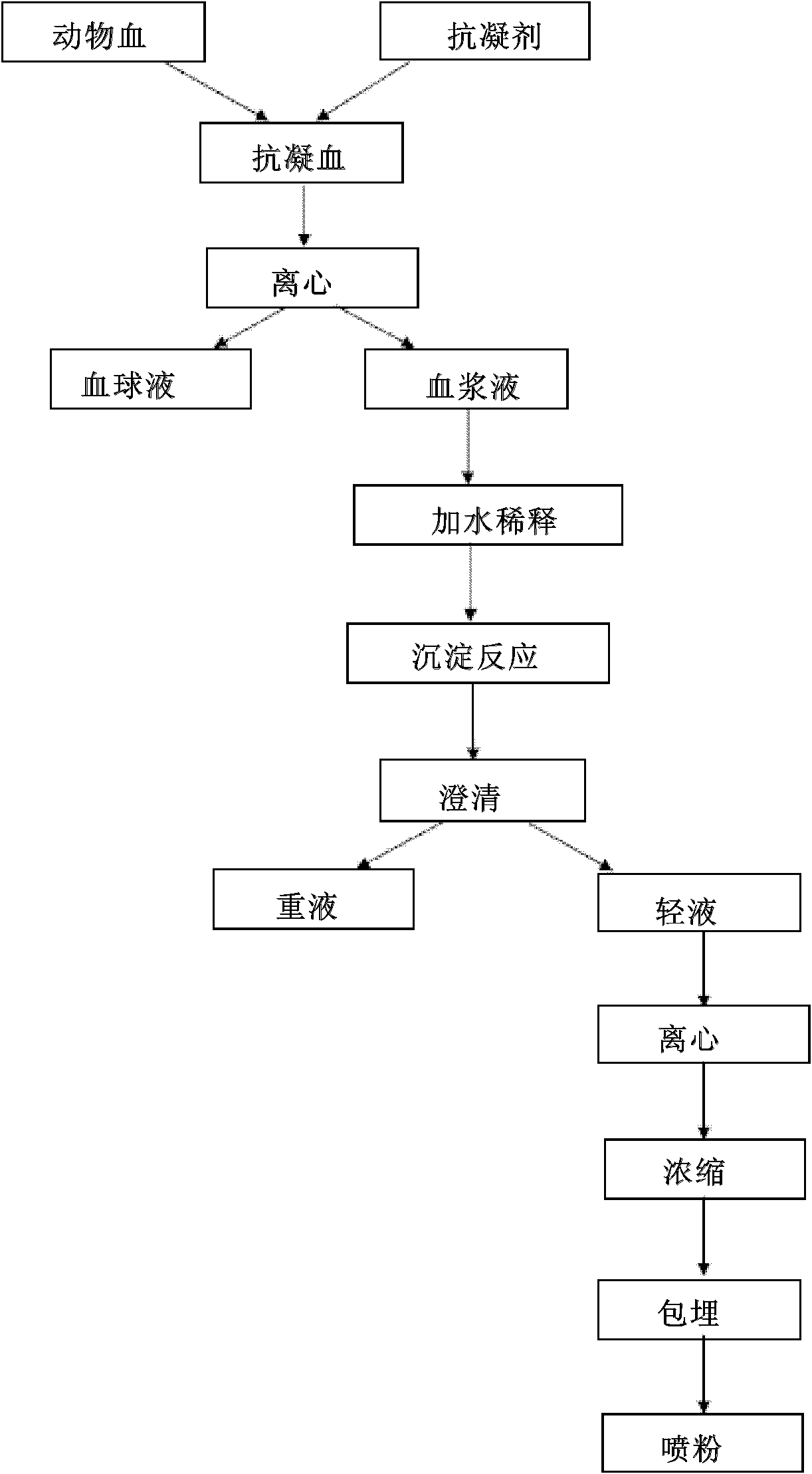

[0136] 1. Whole blood anticoagulation

[0137] The anticoagulant potassium oxalate, sodium chloride, and sodium citrate were mixed according to the ratio of 3:2:5 to configure an anticoagulant solution with a concentration of 10%, with a total volume of 1 kg, and added to 9 kg of whole blood to obtain Anticoagulated whole blood;

[0138] 2. Centrifuge

[0139] Centrifuge the anticoagulated whole blood through a tube centrifuge (16,000 rpm) to obtain 5.3 kg of light liquid plasma and 4.7 kg of heavy liquid blood cells;

[0140] 3. Dilution

[0141] Add 40 kg of pure water to the centrifuged light plasma to obtain the diluted plasma;

[0142] 4. Precipitation reaction

[0143] Addition of FeCl to diluent plasma 3 , so that FeCl in the liquid 3 The concentration is 5mmol / L, the pH of the material is adjusted to 3.5, the temperature is 45°C, and the precipitation reaction is carried out for 1 hour to obtain the reaction solution;

...

Embodiment 2

[0158] mass production of immunoglobulin G

[0159] 1. Whole blood anticoagulation

[0160] Take 1 ton of pig blood, mix the anticoagulants potassium oxalate, sodium chloride, and sodium citrate in a ratio of 3:2:5, take 8 kilograms to prepare an anticoagulant solution with a concentration of 10%, and add it while stirring. Obtain anticoagulated whole blood;

[0161] 2. Centrifuge

[0162] Centrifuge the anticoagulated whole blood through a tube centrifuge (16,000 rpm) to obtain 600 kg of light liquid plasma and 480 kg of heavy liquid blood cells;

[0163] 3. Dilution

[0164] Add 4000 kg of pure water to 600 kg of plasma obtained by centrifugation to obtain the diluted plasma;

[0165] 4. Precipitation reaction

[0166] Addition of FeCl to diluent plasma 3 , so that FeCl in the liquid 3 The concentration is 5mmol / L, the pH of the material is adjusted to 5, the temperature is 40°C, and the precipitation reaction is carried out for 2 hours to obtain the reaction solution...

Embodiment 3

[0181] Preparation of Feed Containing Immunoglobulin G and Its Effect

[0182] Feed 1

[0183] There are 99 parts of commercially available suckling pig feed and 1 part of immunoglobulin G.

[0184] Feed 2

[0185] 100 parts of commercially available suckling pig feed.

[0186] The above two feeds were fed to piglets, and the results showed that the diarrhea rate of piglets fed with immunoglobulin products could be reduced by more than 50%, and the blood immunoglobulin content increased by more than 40%. It shows that the immunoglobulin G prepared by the method of the invention has significant curative effect on intestinal diseases of young animals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com