Thermal infrared imager inhomogeneous correction coefficient generation and control method

A non-uniform correction and infrared thermal imaging camera technology, applied in the field of infrared thermal imaging, can solve the problems of slow flash reading and writing speed, slow loading and downloading process, etc., to avoid frequent pauses in the picture, reduce flash storage capacity, and improve circuit The effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

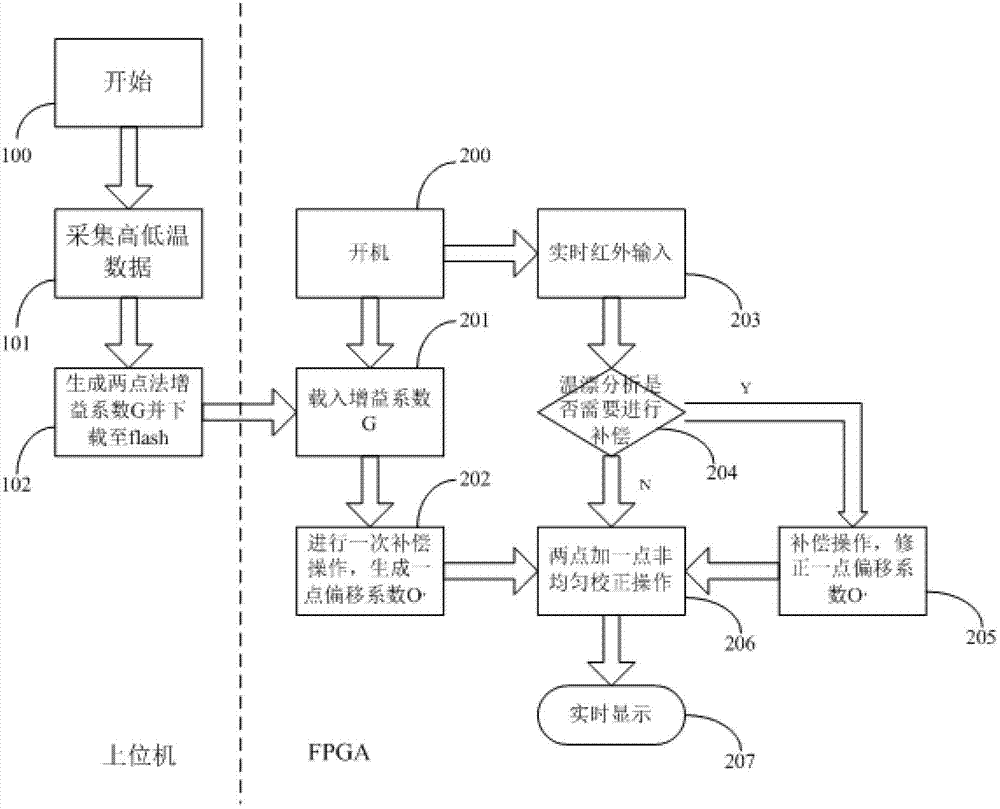

[0033] Below according to the attached figure 1 Illustrate the realization process of the present invention:

[0034] 1. Step 100 is to start the preparation phase.

[0035] 2. Step 101 is the data collection stage. The black body provides high and low temperature scenes respectively, and the responses of each pixel of the detector are converted into digital signals by ADC and collected to the host computer.

[0036] 3. Step 102 obtains the gain coefficient G of the two-point method through calculation. G is a 15-bit unsigned number, and the obtained gain coefficient generally does not exceed the range of 20%. At the same time, step 102 downloads the gain coefficient G to the parallel flash through the serial port. The baud rate is selected as 115200. The writing speed of the selected parallel flash is faster than that of the serial port, so the gain can be directly written into the flash without buffering.

[0037] 4. Step 200 is the start-up phase of the thermal imager.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com